Offshore oil platform cabin tank circulating stirring flushing method and stirring flushing system thereof

An offshore oil and circulating stirring technology, which is applied in the field of offshore oil platform cleaning and stirring equipment, can solve the problem that the cleaning device and manual cleaning cannot effectively complete the tank cleaning and stirring, pollute the platform environment and the marine environment, large manpower and Material resources and other issues, to achieve ideal results, avoid personnel poisoning accidents, and use good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings, without limiting the protection scope of the present invention.

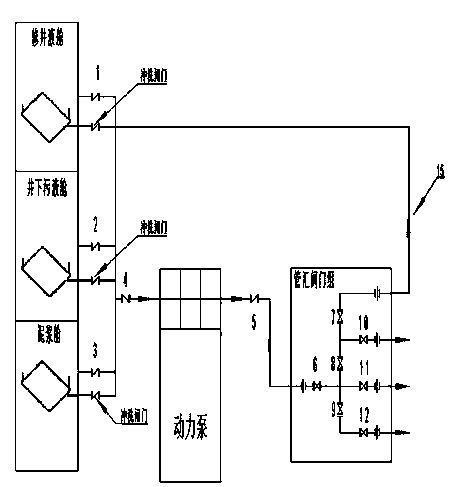

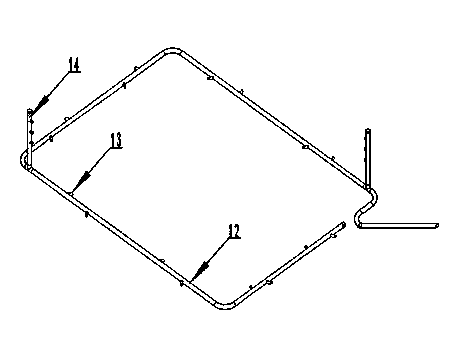

[0016] The method of circulating agitation and flushing for offshore oil platform tanks is to install a hydraulic jet agitation cleaning device in the offshore oil platform tanks, and use the offshore oil platform's own tanks, power pumps and manifold valves to pass through the water pipeline and the tank installed The hydraulic jet stirring cleaning device is connected to form a stirring flushing system.

[0017] see figure 1 with figure 2 , the agitation and flushing system includes tanks, power pumps and manifold valve groups, the tanks, power pumps and manifold valve groups are connected through water pipelines, a flushing gate is connected in parallel at the outlet gate of each tank, and the manifold valve group is added A stirring and flushing gate 7 and a stirring and flushing pipeline 15 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com