Drilling positioning fixture for drilling flange disc mounting hole in multi-stage pump body

A technology for drilling jigs and mounting holes, which is applied to positioning devices, drilling molds for workpieces, clamping, etc., can solve the problems of inconvenient disassembly and low clamping degree, and achieve convenient disassembly and assembly, simple structure, The effect of high clamping degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

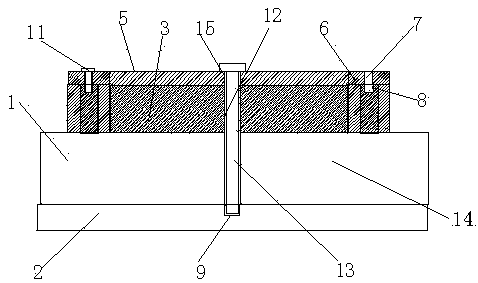

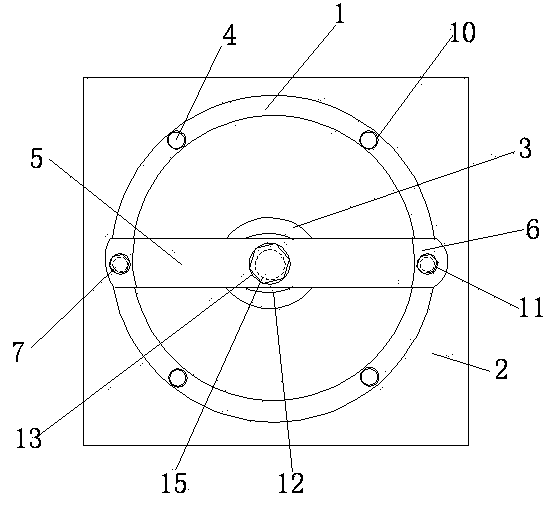

[0012] Examples such as figure 1 , figure 2 As shown, a drilling positioning jig for drilling flange mounting holes on the pump body of a multistage pump includes a drilling mold base 1 and a drilling mold base fixing device arranged on a base 2, and is characterized in that the drilling mold The base 1 is in the shape of a ring, and an inner support block 3 is provided in the middle of the jig base 1, and a group of positioning jig holes 4 are arranged in a ring around the jig base 1;

[0013] The fixing device of the drilling base is a connecting plate 5 with clamping blocks 6 at both ends and a through hole 15 in the middle. The clamping blocks 6 are reverse U-shaped, and fixing screw holes are set at the top of each clamping block 6 7. A second fixing screw hole 8 corresponding to the fixing screw hole 7 is provided on the peripheral position of the drilling base 1, and the middle part of the connecting plate 5 is provided with a middle locking hole 12, and the middle lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com