Anti-backlash mode adjusting device

A mold adjustment device and anti-backlash technology, which is applied in the field of injection molding machine mold adjustment, can solve problems such as difficulty in adjusting the required clamping force, different template positions, and accumulation of processing errors, so as to eliminate the reciprocating rotation gap and avoid the accumulation of errors , The effect of convenient mold adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

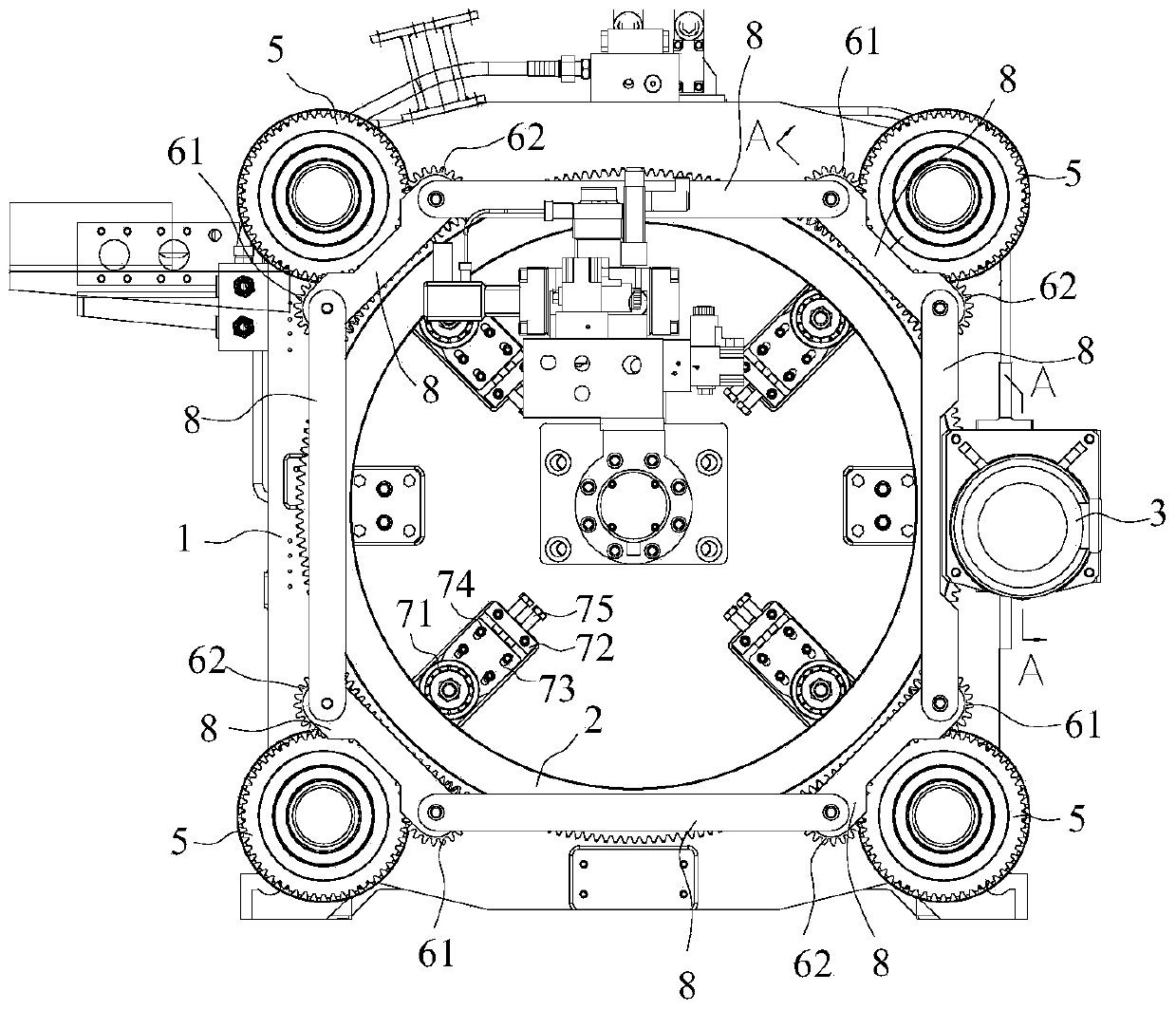

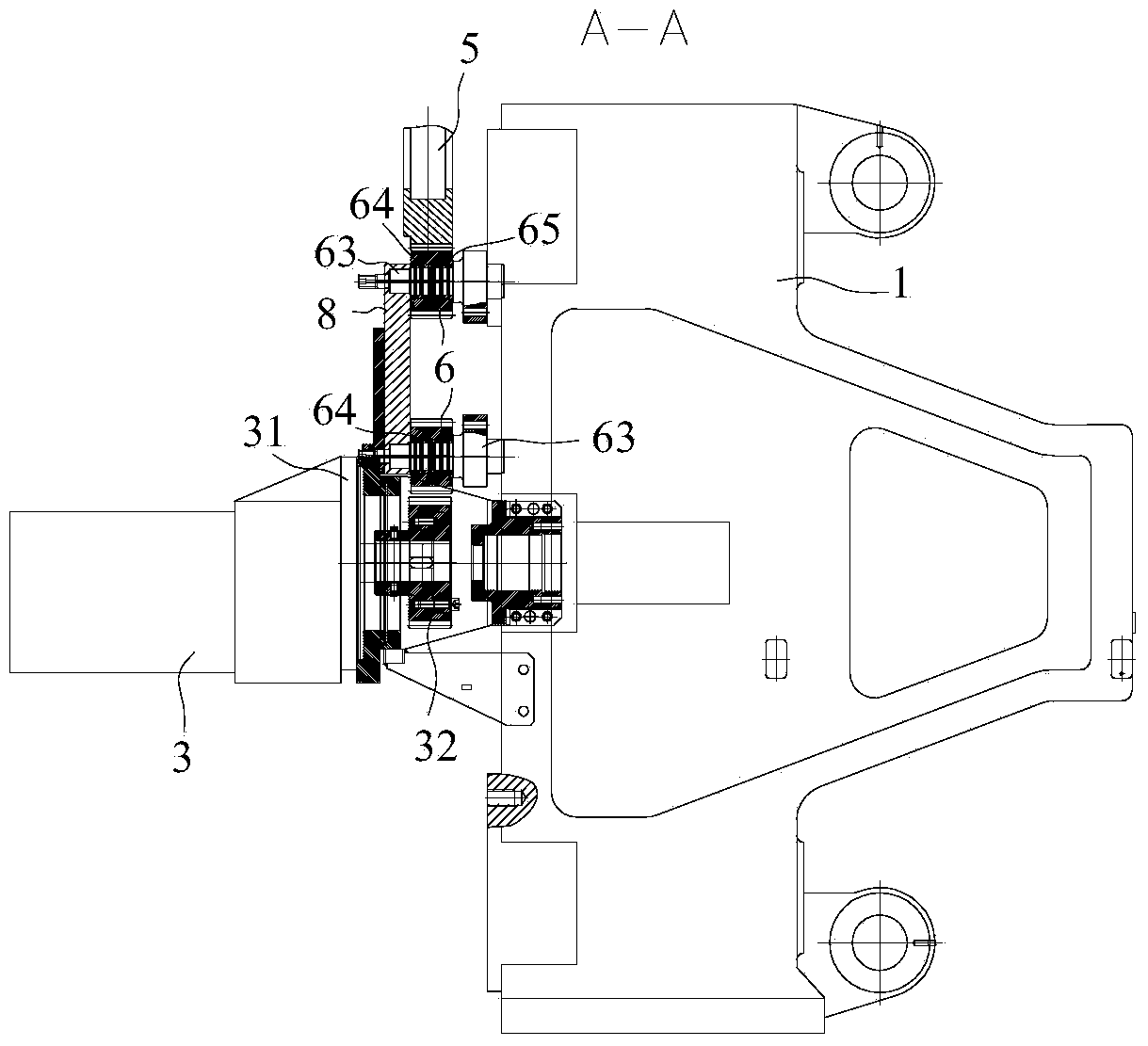

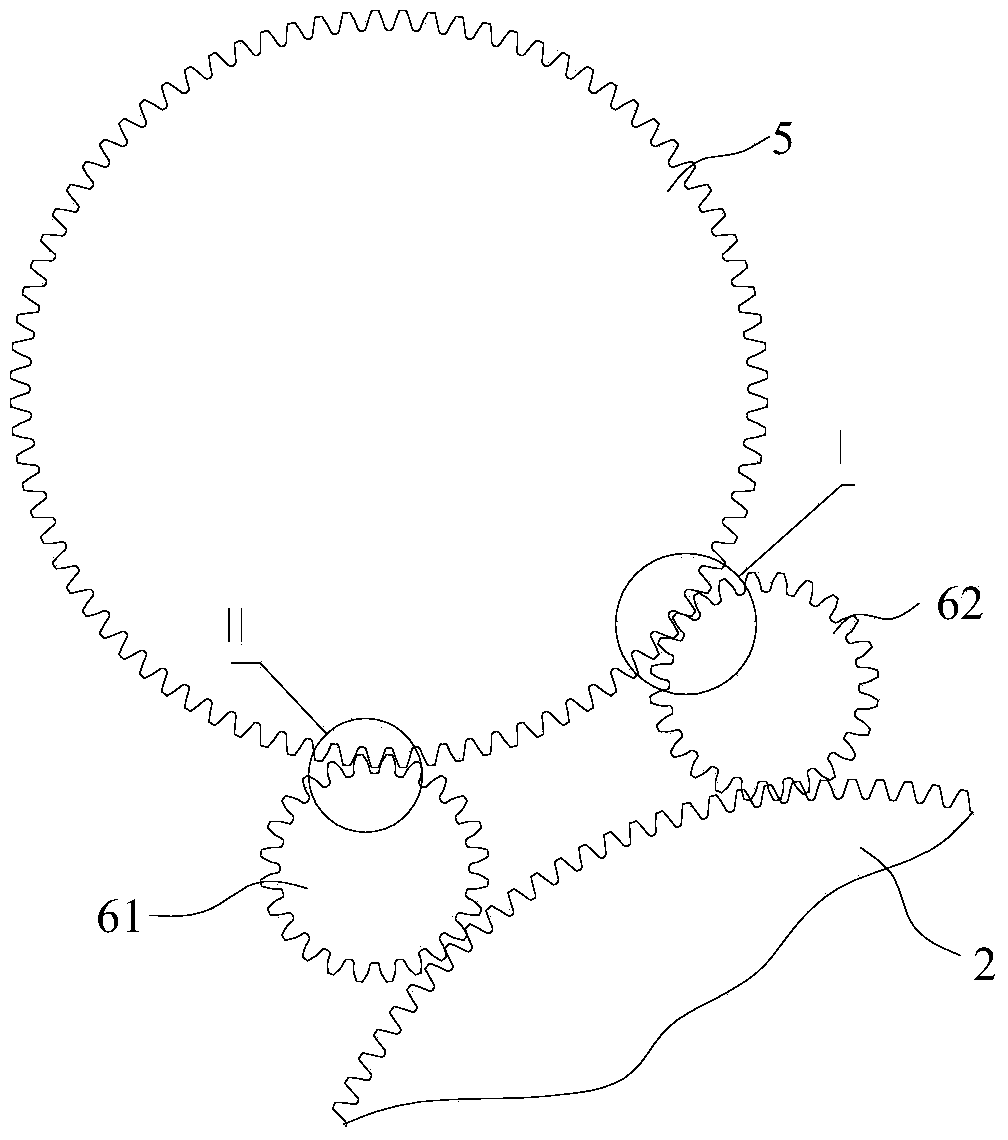

[0027] refer to Figure 1 to Figure 6 , the present invention provides an anti-backlash mold adjusting device, comprising a base 1, a mold adjusting gear 2 arranged on the end face of the base 1, a mold adjusting motor 3 driving the mold adjusting gear 2, and a mold adjusting gear located 2 a plurality of pull rods 4 around, each of the pull rods 4 is equipped with a mold adjustment nut 5 on the outside of the mold adjustment gear 2, and the end surface of the base 1 is provided with a transmission mold adjustment gear 2 and each mold adjustment nut 5 The intermediate gear 6, the intermediate gear 6 includes the first intermediate gear 61 and the second intermediate gear 62 arranged on both sides of each mold adjusting nut 5, the first intermediate gear 61 and the mold adjusting nut 5 and the mold adjusting bull gear 2 The tooth side clearance in the counterclockwise rotation direction of the first intermediate gear 61 is zero, and the tooth side clearance between the second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com