Worktable assembly of DLP (Digital Light Processing) photo-curing 3D printer

A 3D printer and workbench technology, applied in the field of workbench components of DLP light-cured 3D printers, can solve the problems of easy damage to the printer frame, affecting the service life of the 3D printer, and affecting the forming effect of objects, so as to improve economic benefits and improve printing quality. The effect of surface finish on objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

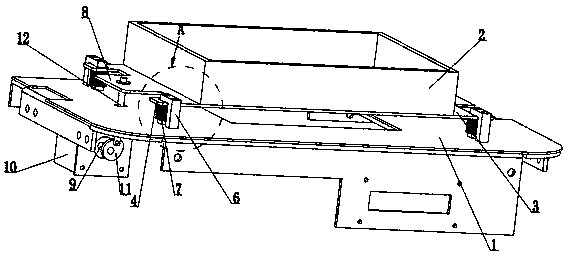

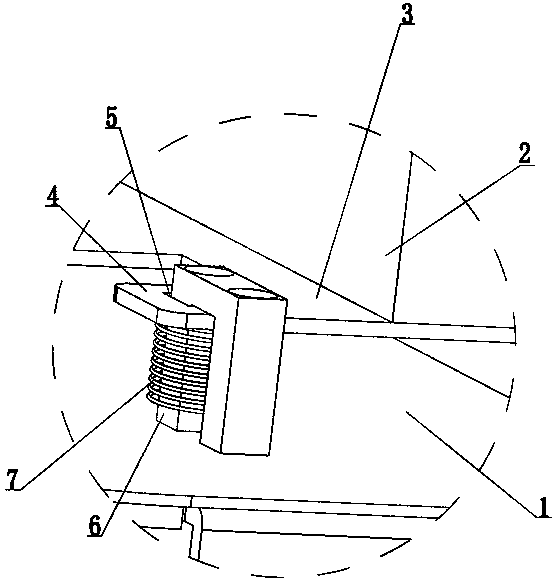

[0032] Such as figure 1 with figure 2 As shown, a workbench assembly of a DLP light-curing 3D printer provided in this embodiment includes a workbench 1 and a transparent resin tank 2, and an installation bottom frame 3 is provided above the workbench 1, and the installation The bottom frame 3 is rectangular and has second flanges 4 at its four corners. Each of the second flanges 4 is provided with a first through hole 5, and U-shaped connectors are connected in series. 6. Both ends of the U-shaped connector 6 are fixed to the base surface of the table 1, and a coil spring 7 is sleeved on the U-shaped connector 6, and the coil spring 7 is located between the second flange 4 and the base of the table 1. Between the two surfaces, a first flange 8 is also provided on one side edge of the above-mentioned installation bottom frame 3, and two flanges 8 are provided below the workbench 1 when receiving the printing layer 24 and the bottom surface 23 of the transparent resin tank 2....

Embodiment 2

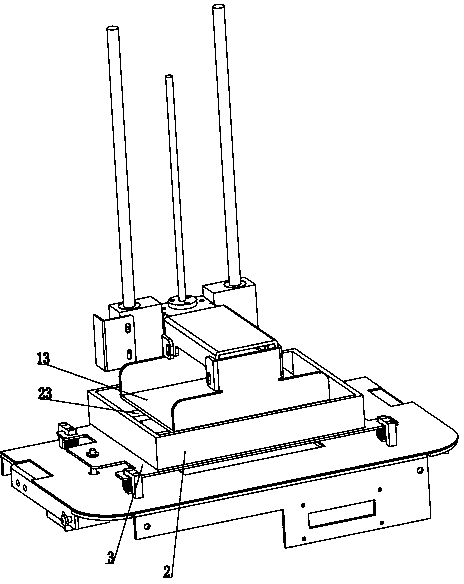

[0035] Such as Figure 4 As shown, a workbench assembly of a DLP light-curing 3D printer provided in this embodiment includes a workbench 1 and a transparent resin tank 2, and an installation bottom frame 3 is provided above the workbench 1, and the installation The bottom frame 3 is rectangular and has second flanges 4 at its four corners. Each of the second flanges 4 is provided with a first through hole 5, and U-shaped connectors are connected in series. 6. Both ends of the U-shaped connector 6 are fixed to the base surface of the table 1, and a coil spring 7 is sleeved on the U-shaped connector 6, and the coil spring 7 is located between the second flange 4 and the base of the table 1. Between the two surfaces, a first flange 8 is also provided on one side edge of the above-mentioned installation bottom frame 3, and the servo motor 10 is above the first flange 8, and the output shaft 9 of the servo motor 10 is connected with Eccentric roller 14. When the printing layer 2...

Embodiment 3

[0037] The workbench assembly of a kind of DLP photocuring 3D printer provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 5 As shown, the specific structure in which the bottom frame 3 is connected to the base surface of the workbench 1 through elastic components in the embodiment is as follows: the bottom frame 3 is rectangular, and second flanges 4 are provided at its four corners. , each of the second flanges 4 is fixed with an elastic rubber 15 , and the other end of each elastic rubber 15 is directly fixed to the base surface of the workbench 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com