Rotary system and crane

A slewing system and slewing motor technology, applied in cranes, mechanical equipment, fluid pressure actuating devices, etc., can solve problems such as the influence of the operator's operating proficiency, improve fretting and stability, improve performance, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

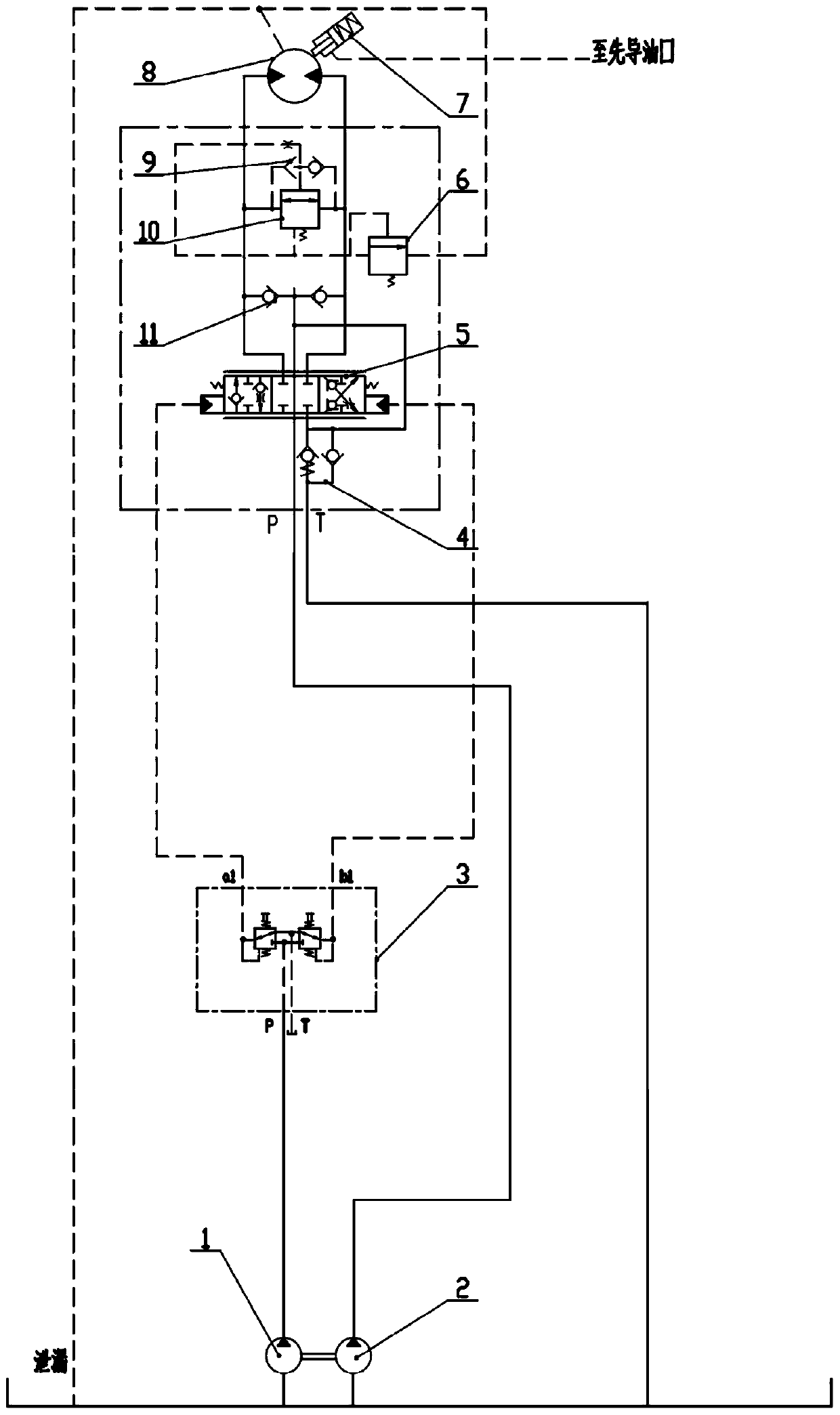

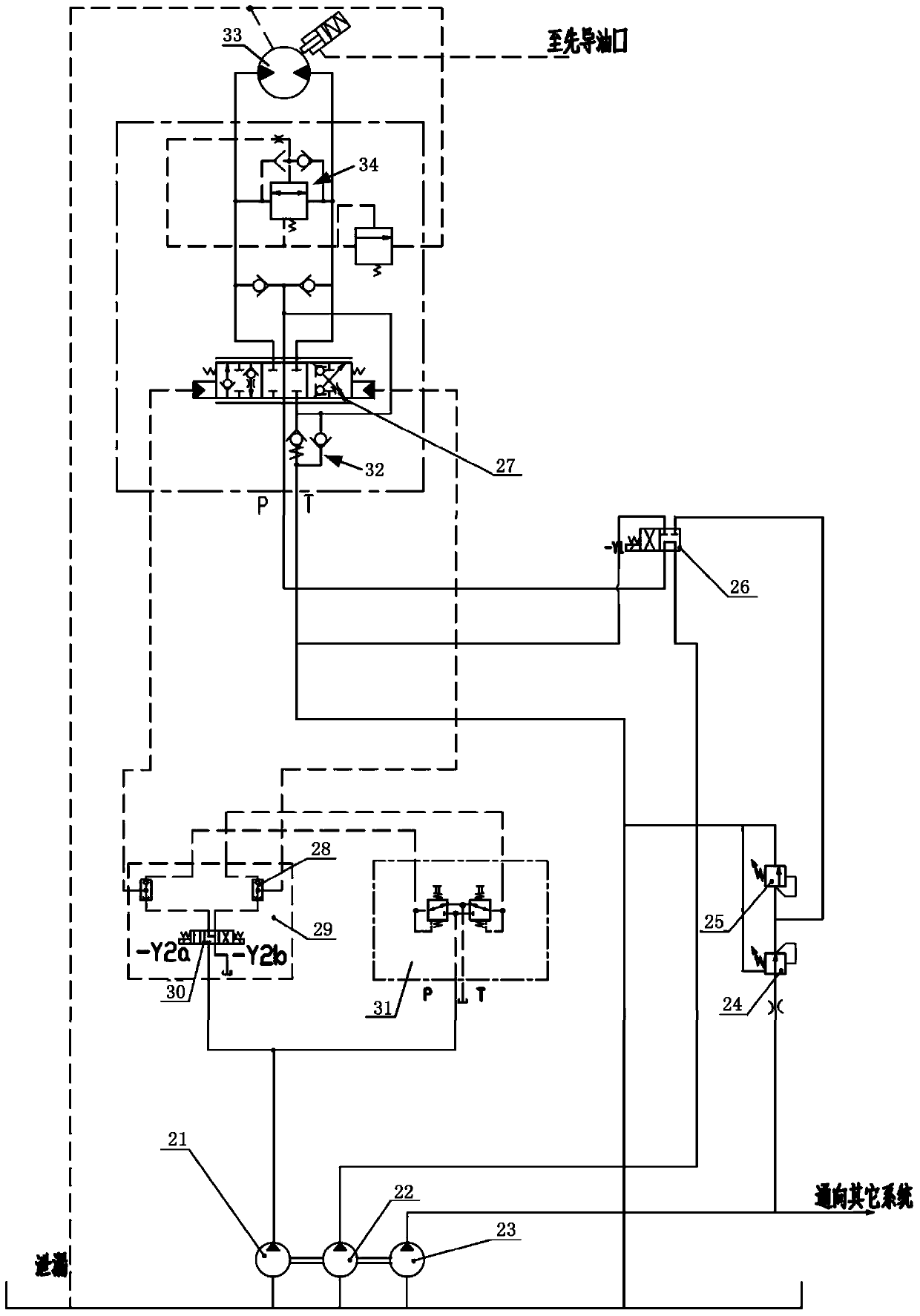

[0051] Combine below figure 2 A more detailed elaboration of the technical solution provided by the present invention, a technical solution obtained by replacing any technical means provided by the present invention or combining any two or more technical means or technical features provided by the present invention with each other All should be within the protection scope of the present invention.

[0052] An embodiment of the present invention provides a slewing system, including: a working oil pump 22 , a micro-motion oil pump 23 , a rotary reversing valve 27 , and a switching valve 26 . The working oil pump 22 is used to provide working pressure oil for the rotary reversing valve 27 , and the working pressure oil is used to flow to the rotary motor 33 to realize the working steering of the rotary motor 33 . The inching oil pump 23 is used to provide the inching pressure oil for the rotary reversing valve 27 , and the inching pressure oil is used to flow to the slewing mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com