Preparation method of thermoplastic polyester elastomer

A technology of thermoplastic polyester and elastomer, which is applied in the field of preparation of thermoplastic polyester elastomer, can solve the problems that cannot meet the light stability of high-performance TPEE products, and achieve the effect of improving light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

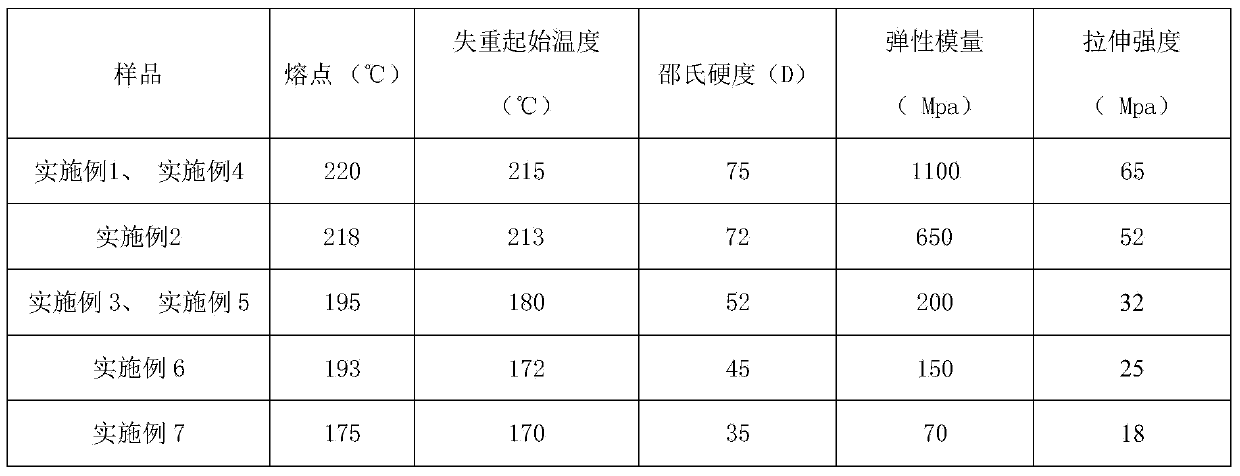

Examples

Embodiment 1

[0017] Embodiment 1: In 20 liters of polymerization reactors, add 3.4 kilograms of terephthalic acid (PTA), 3.2 kilograms of 1,4-butanediol (BDO), the mole of 1,4-butanediol and terephthalic acid Ratio is 1.7, antioxidant (BHT) 25 grams, addition accounts for 0.5% of the theoretical quality of the polyester elastomer that makes, benzophenone class ultraviolet absorber (UV-531), benzotriazole class ultraviolet absorber UV-326) and 2.5 grams each of hindered amine light stabilizer (770), the amount added accounts for 0.05% of the theoretical mass of the obtained polyester elastomer, 3.4 grams of tetrabutyl titanate, set the esterification kettle to heat The temperature is 220°C, the esterification pressure is 100Kpa (absolute pressure), and the esterification reaction is carried out. When the esterification is 180 minutes to 200 minutes and the water output reaches more than 1700ml, add 0.5 kg of polytetrahydrofuran (number average molecular weight: 2000), and the addition amount...

Embodiment 2

[0018] Embodiment 2: In 20 liters of polymerization reactors, add 3.4 kilograms of terephthalic acid (PTA), 3.4 kilograms of 1,4-butanediol (BDO), the mole of 1,4-butanediol and terephthalic acid Ratio is 1.9, antioxidant (BHT) 43 grams, addition accounts for 0.8% of the theoretical quality of the polyester elastomer that makes, benzophenone class ultraviolet absorber (UV-531), benzotriazole class ultraviolet absorber UV-326) and hindered amine light stabilizer (770) each 4.3 grams, the amount of addition accounts for 0.08% of the theoretical mass of the obtained polyester elastomer, 3.4 grams of tetrabutyl titanate, set the esterification kettle to heat The temperature is 220°C, the esterification pressure is 100Kpa (absolute pressure), and the esterification reaction is carried out. When the esterification is 200 minutes to 220 minutes, and the water output reaches 1800ml or more, add 0.8 kg of polytetrahydrofuran (number average molecular weight 1000), and the amount added i...

Embodiment 3

[0019] Embodiment 3: In 20 liters of polymerization reactors, add 3.4 kilograms of terephthalic acid (PTA), 4.1 kilograms of 1,4-butanediol (BDO), the mole of 1,4-butanediol and terephthalic acid Ratio is 2.2, antioxidant (BHT) 63 grams, addition accounts for 1% of the theoretical quality of the polyester elastomer that makes, benzophenone class ultraviolet absorber (UV-531), benzotriazole class ultraviolet absorber UV-326) and 3.2 grams of hindered amine light stabilizer (770), the amount added accounts for 0.1% of the theoretical mass of the obtained polyester elastomer, 3.4 grams of tetrabutyl titanate, set the esterification kettle to heat The temperature is 220°C, the esterification pressure is 100Kpa (absolute pressure), and the esterification reaction is carried out. When the esterification is 220 minutes to 240 minutes, and the water output reaches more than 2000ml, add 1.93kg of polytetrahydrofuran (number average molecular weight 1000), and the addition amount is abou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap