Reverse building method rear-inserting steel pipe column vertical positioning device and construction method thereof

A technology of vertical positioning and steel pipe columns, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as high cost, failure to meet design requirements, long remedial construction and treatment period, etc., to ensure safety, simple production, The effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

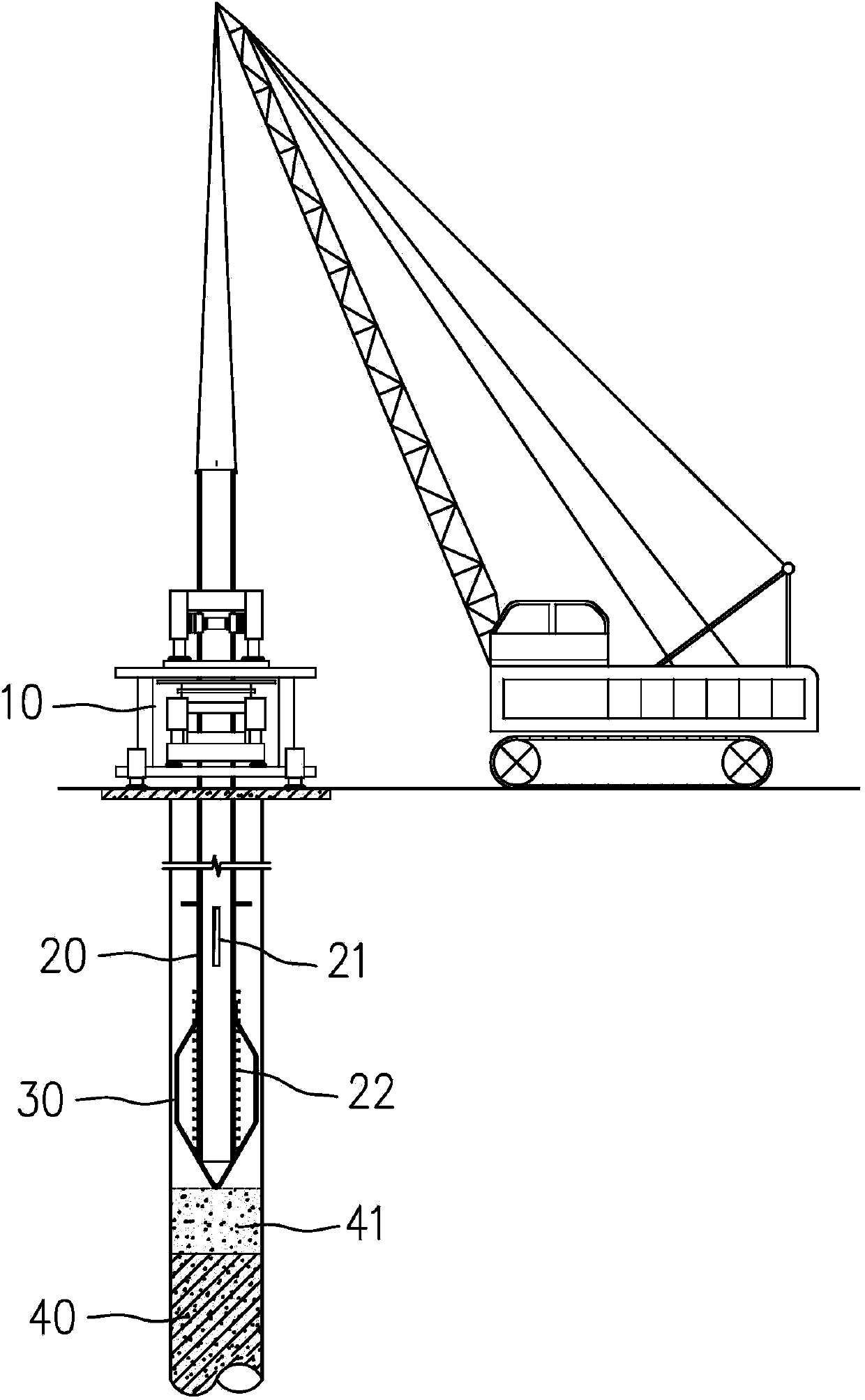

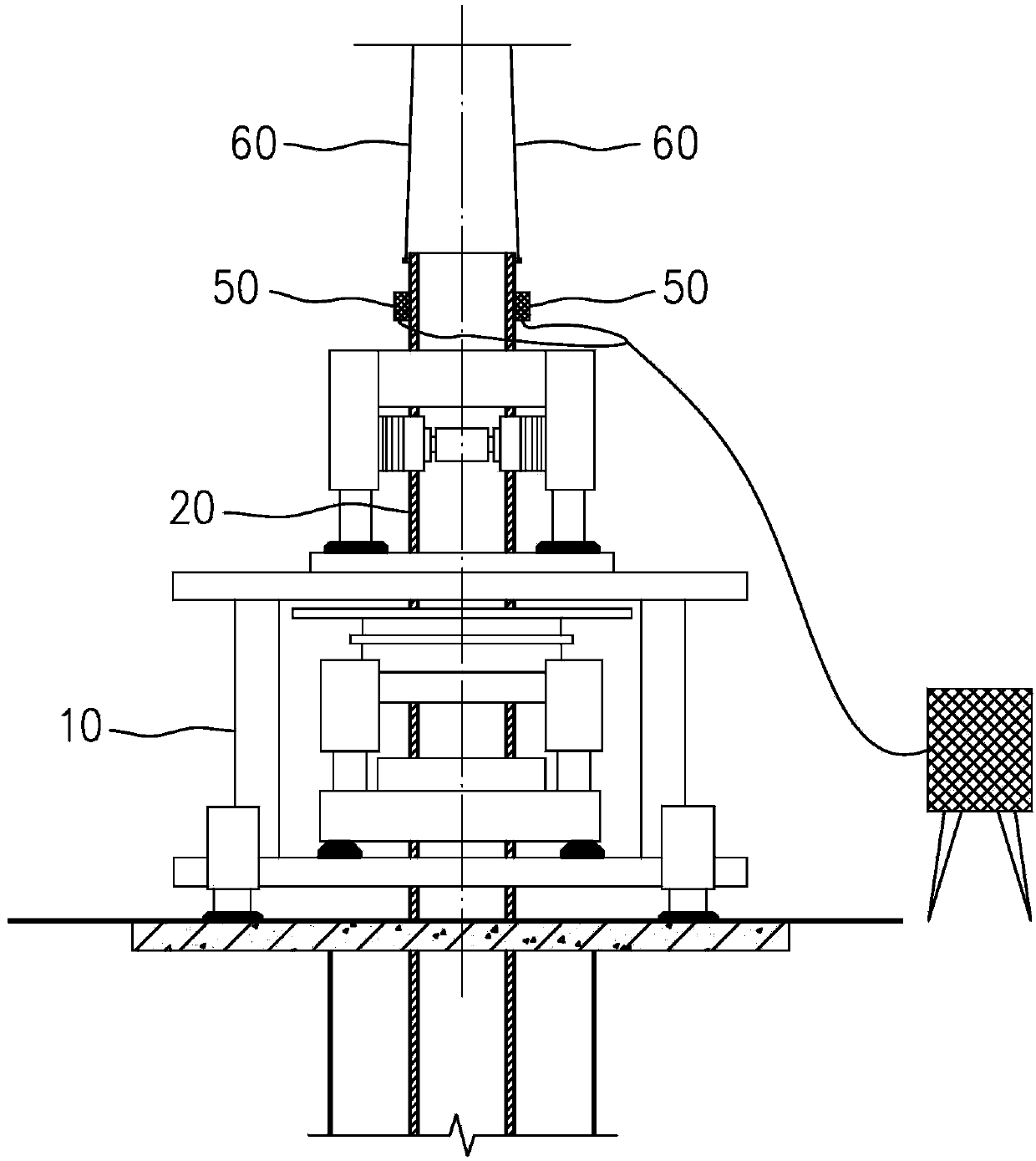

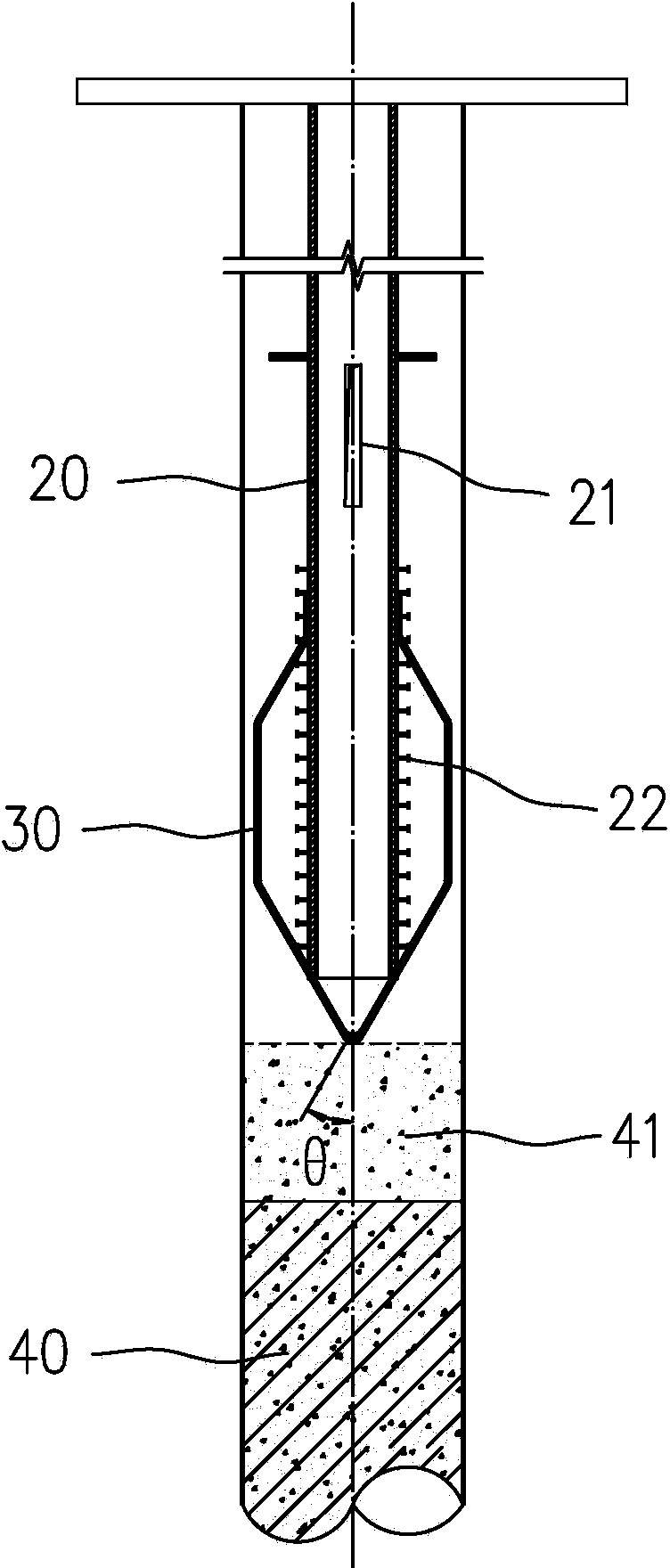

[0036] Such as Figure 1~4 The vertical positioning device for post-insertion steel pipe column shown in the reverse method includes a crane, two steel wire ropes 60 for suspending the steel pipe column 20, and a hydraulic press 10. The upper end of the steel pipe column 20 protrudes outside the hydraulic press 10, and the steel pipe The lower end of the column 20 is open; the steel pipe column 20 protruding from the upper side of the hydraulic machine 10 is provided with four vibrators 50, and the four vibrators 50 are in pairs, and each pair of vibrators 50 is along the The axis of the steel pipe column 20 is symmetrically distributed, and all the vibrators 50 are evenly distributed on the circumference of the column body along the annular wall of the steel pipe column 20; anchors 22 are arranged on the lower end of the steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com