Argon recycling and filling device

A technology of argon gas and pressure regulating device, which can be used in container filling method, equipment loaded into pressure container, gas/liquid distribution and storage, etc., and can solve problems such as economic loss and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

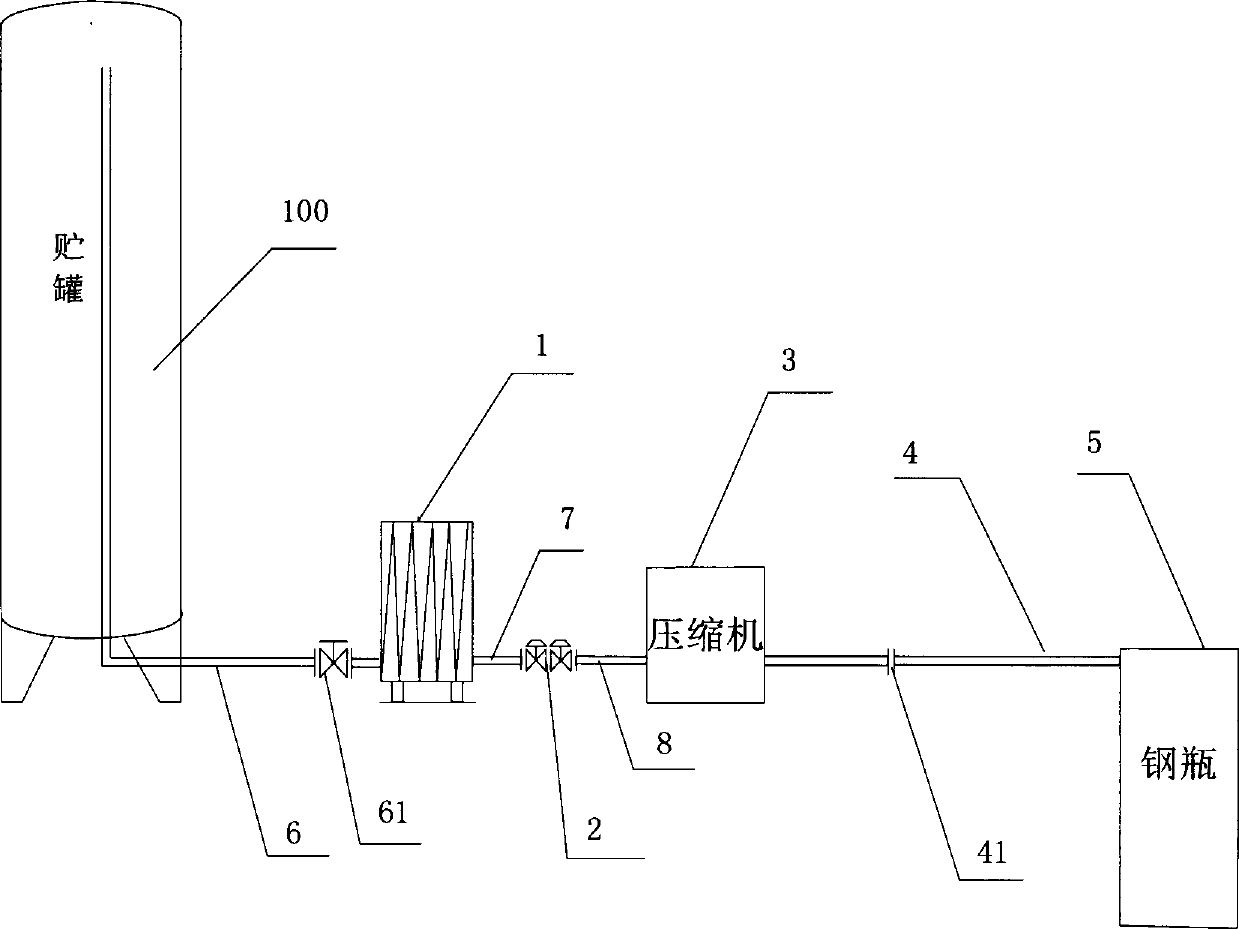

[0010] see figure 1 , the argon recovery bottle filling device of the present invention comprises a vaporizer 1, a two-stage pressure regulating device 2, a compressor 3, a filling bus bar 4, a steel cylinder 5, a first pipeline 6, a second pipeline 7 and a third pipeline 8, in:

[0011] The storage tank 100 is used to store liquid argon, such as the AFL-100 / 06 type cryogenic liquid storage tank; in order to maintain its own pressure, a certain amount of gaseous argon needs to be discharged regularly according to the standard;

[0012] The first pipeline 6 is connected to the storage tank 100 and the vaporizer 1, and a first valve 61 is arranged on the first pipeline 6, and the first valve 61 is opened when the gas needs to be discharged, so that gaseous argon enters the vaporizer 1;

[0013] The second pipeline 7 is connected to the vaporizer 1 and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com