Pressure-bearing vaporization heat dissipating device

A radiator and vaporization chamber technology, applied in the field of heat dissipation, can solve the problems of large space occupation, installation of cooling fans, large area, etc., and achieve the effects of simple structure, high heat dissipation efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

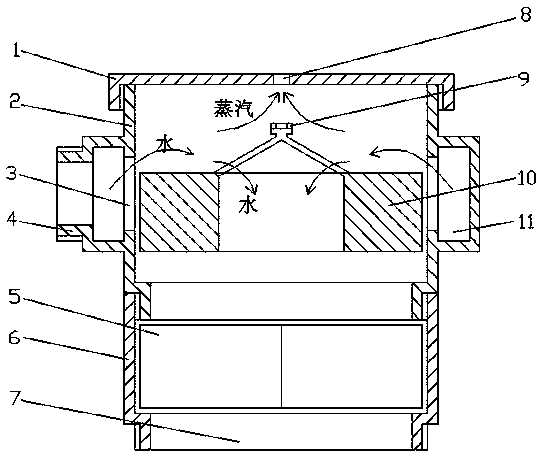

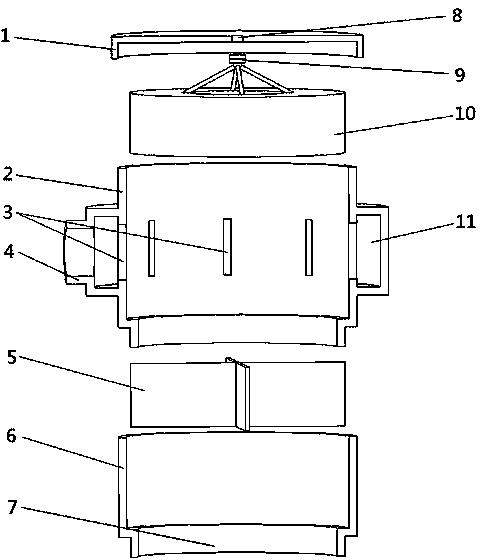

[0018] Below in conjunction with accompanying drawing, the present invention will be further described. The following embodiments use a water pump as a power source to enable those skilled in the art to better understand the present invention, and do not limit the present invention in any way.

[0019] The embodiment of pressure-bearing vaporization radiator of the present invention: as figure 1 As shown, the pressure-bearing vaporization radiator includes a shell, a liquid inlet (3), a relatively liquid outlet (7), and an exhaust port (8). Compared with the liquid outlet (7), the liquid inlet (3) has a smaller geometric size or greater fluid resistance, and the exhaust port (8) is located on the upper part of the liquid outlet (7). The housing is composed of a vaporization chamber (2) and a diversion chamber (6). The vaporization chamber (2) is located on the upper part of the diversion chamber (6). The vaporization chamber (2) and the diversion chamber (6) communicate with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap