A double-ended calibration device and calibration method

A technology of a calibration device and a calibration method, which is applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., to achieve the effects of simple calibration methods, high rigidity, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

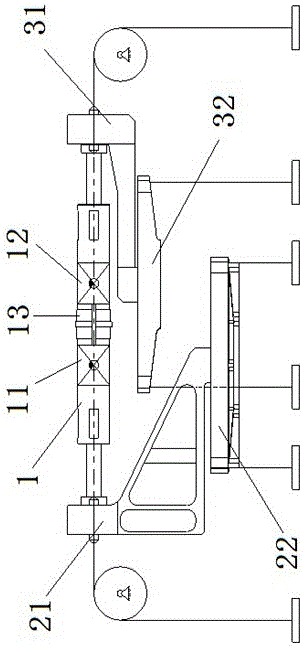

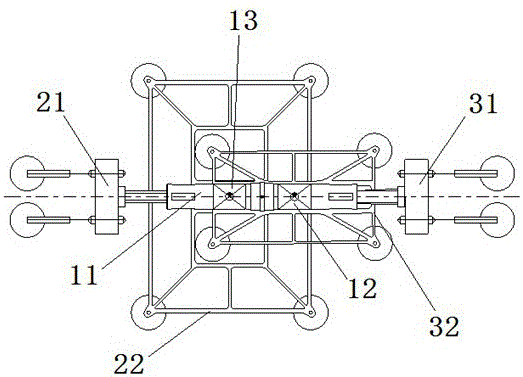

[0029] figure 1 It is the front view of the double-ended calibration device of the present invention. The double-ended calibration device of the present invention mainly includes two sets of "L" shaped sliders and loading heads, which are used in conjunction with each other, wherein one end of the front "L" shaped slider is connected to the The front loading head is connected, and the other end is connected to the front end of the double-ended force measuring device; one end of the rear "L" shaped slider is connected to the rear loading head, and the other end is connected to the rear end of the double-ended force measuring device; the "L" shaped slider The block is the connecting piece between the force measuring device and the loading head, and is provided with a pair of longitudinally symmetrical resistance loading points. The resistance loading point is in the horizontal plane where the axial force direction of the force measuring device is located. The block pulley applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com