equipment for filtering fluids

A technology for filtering fluid and equipment, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve a large number of problems, and achieve the effect of simple design, compact space, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the drawings, the same parts are marked by the same reference numerals, and in some drawings, some reference numerals are omitted for the sake of clarity. Components described individually according to the preferred embodiments of the present invention can be combined arbitrarily in a manner well known to those skilled in the art. The illustrated embodiments are non-limiting in terms of various combinations.

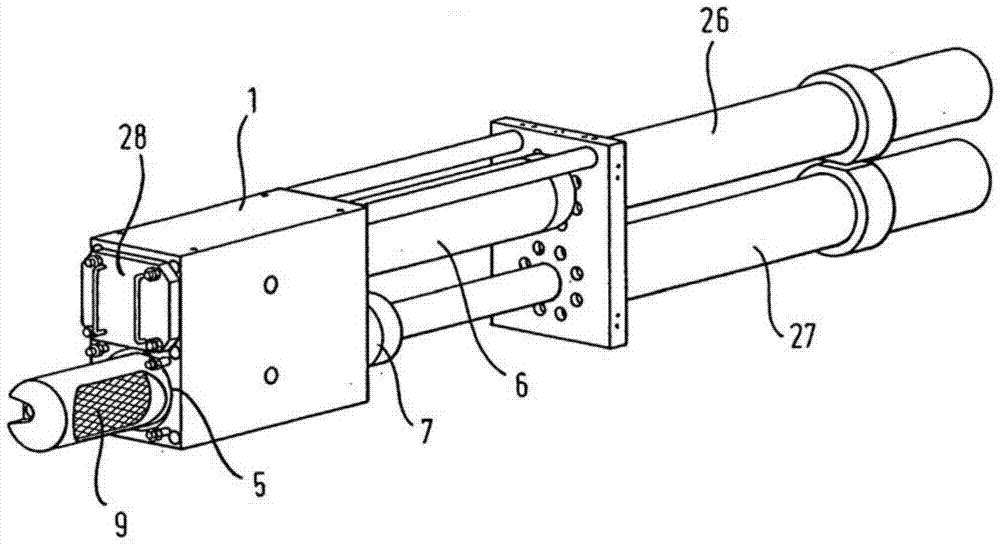

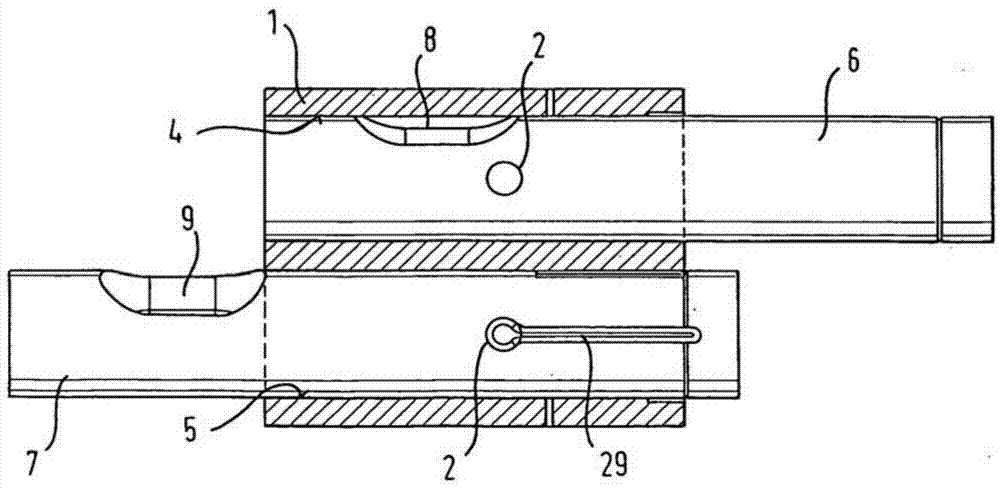

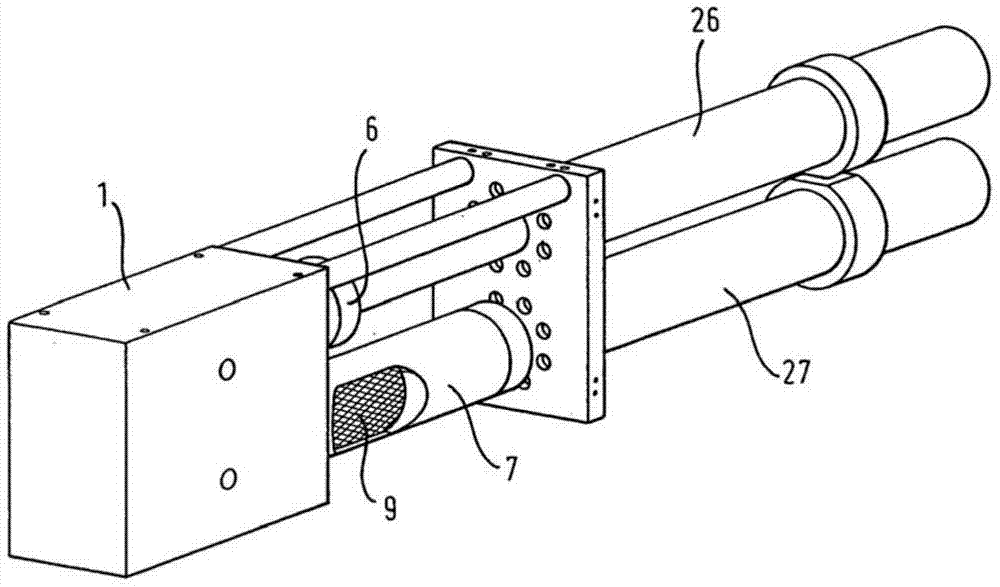

[0050] figure 1 A perspective view of an apparatus for filtering fluid according to a first preferred embodiment of the present invention is shown. In particular, the shown apparatus is used for filtering thermoplastic polymer melts and comprises a housing 1 with bolts 6, 7 which can be inserted into the holes 4, 5 of the housing 1 (the upper hole 4 is in the figure 1 (not visible in ) is movable in a fluid-tight manner, ie axially displaceable and / or radially rotatable. Each bolt 6, 7 comprises at least one filter unit 8, 9 with an inflow side and an outflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com