Braking device having a device spring

A brake device and brake system technology, applied in the direction of brake transmission device, fluid pressure actuation device, brake, etc., can solve the problems of increased manufacturing, assembly, sealing and calibration costs, increased weight, increased space requirements, etc. Achieve the effects of enlarged measurement range, simple connection and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Because the principle structure and working principle of the main components of the hydraulic brake system, such as the pneumatic brake booster or the brake master cylinder, are sufficiently known, a complete detailed explanation thereof is omitted below, and only emphasis is placed on the Invent important features and relationships.

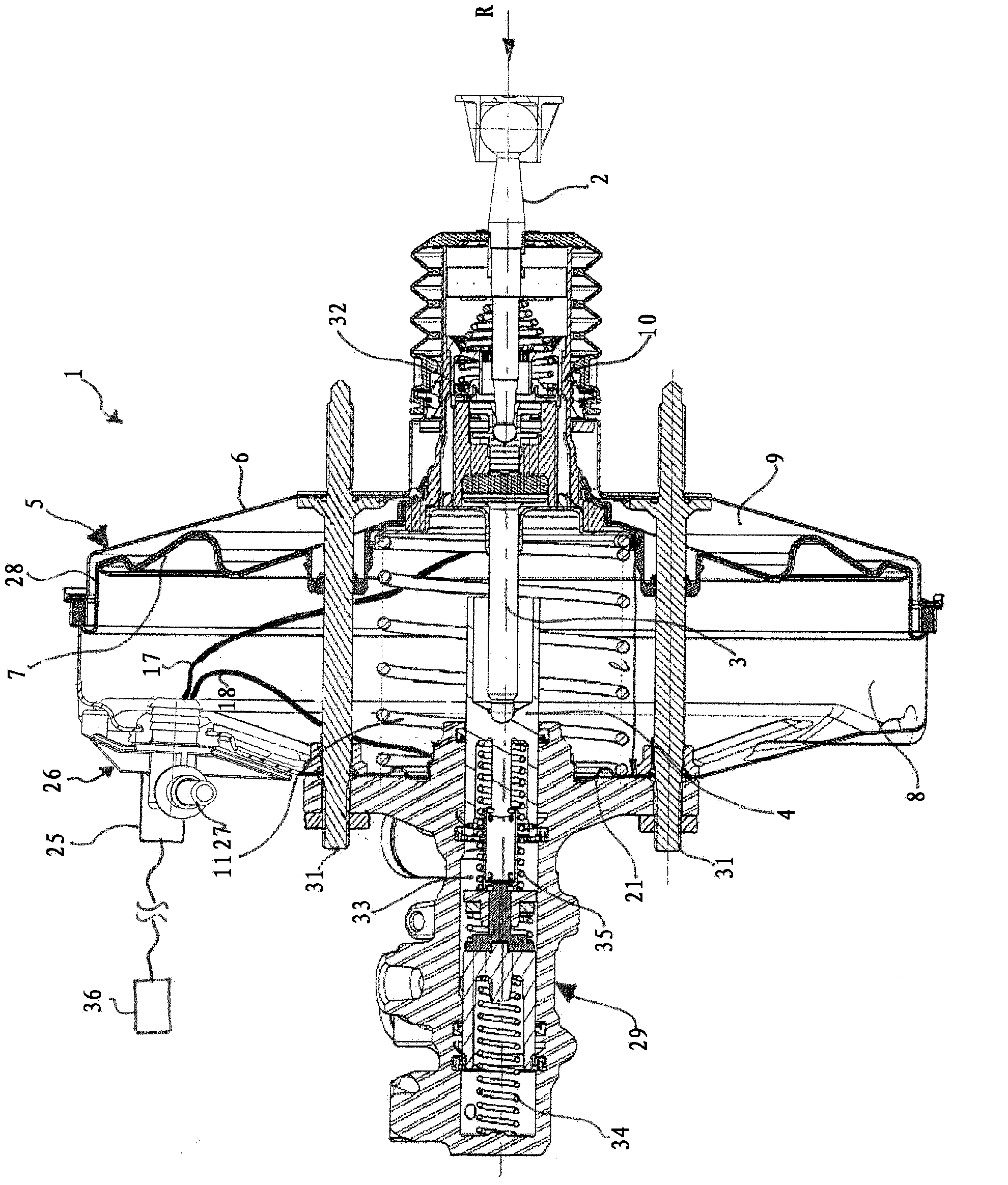

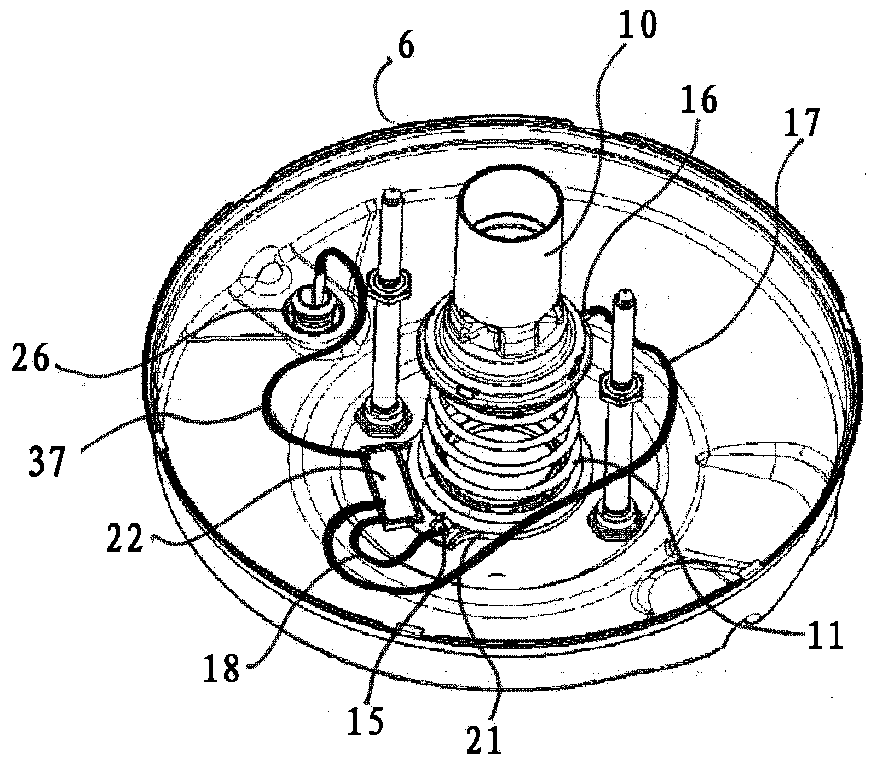

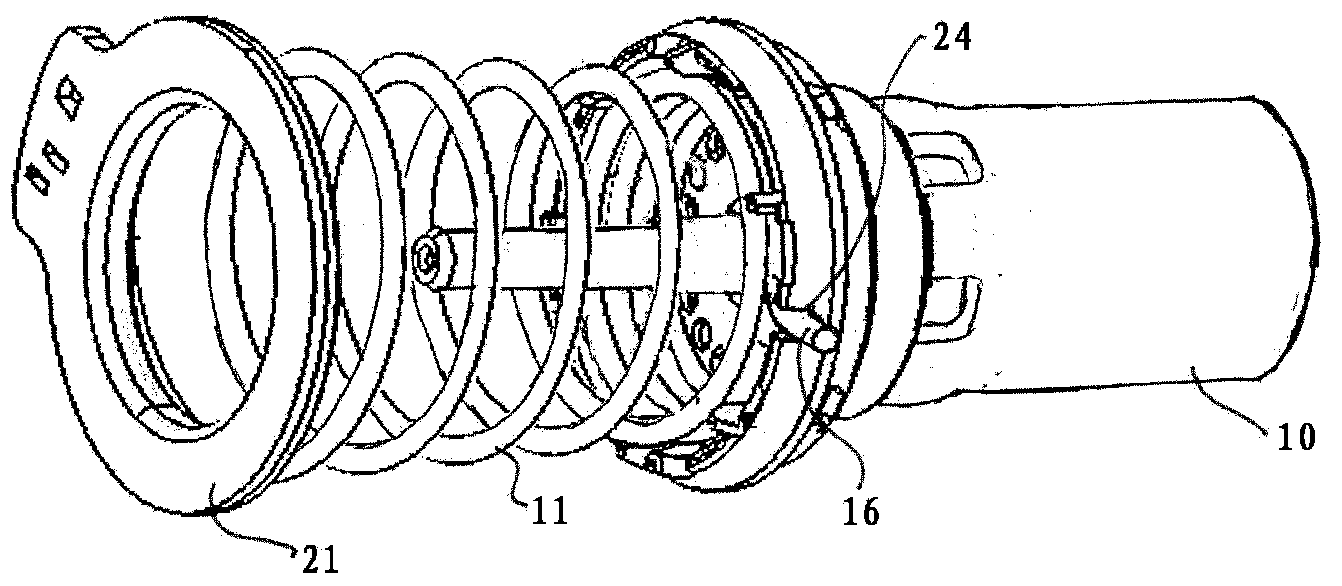

[0033] figure 1

[0034] exist figure 1 A first embodiment of a braking device 1 according to the invention is shown in . The exemplary embodiment shown includes a brake master cylinder 29 which is designed as a so-called tandem master cylinder in the form of a plunger and is fastened to the pneumatic brake booster 5 by means of tension screws 31 . Of course, other embodiments of the brake master cylinder, of a manually or externally actuatable pneumatic, hydraulic or electrohydraulic brake booster and of the fastening means are also possible within the scope of the present invention.

[0035]The brake booster 5 comprises a booster ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com