A gluing machine suitable for bamboo and wood products

A technology of gluing machine and products, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of inconvenient adjustment of gluing amount, uneven gluing, slow speed, etc., to avoid falling directly to the ground, Improve the effect of gluing and optimize the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

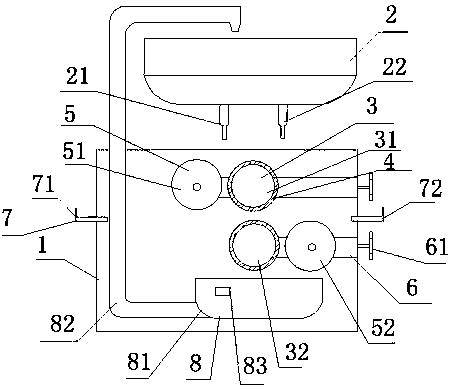

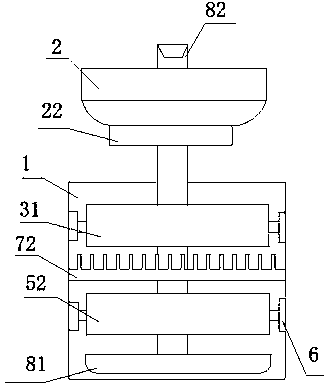

[0026] Example 1, such as figure 1 , figure 2 Shown: a gluing machine suitable for bamboo and wood products, including a frame 1, a gluing device 3 installed on the frame 1 for gluing materials, a gluing device 2 for providing gluing materials to the gluing device 3, and a The glue device 2 includes an upper rubber cylinder 31 and a lower rubber cylinder 32 that are connected to the frame 1 and rotate under the action of an external motor. The lower rubber cylinder 32 is located directly below the vertical position of the upper rubber cylinder 31. The upper rubber cylinder 31 and the lower rubber cylinder The cylinders 32 have the same size, and the outer surface is covered with a rubber contact layer 4 that increases the contact friction with the glue. Glue attaching device 5 for the storage of rubber material required for gluing. The glue attaching device 5 includes an upper attaching glue barrel 51 and a lower attaching glue barrel 52, which are located on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com