Transmission line automatic jacking alignment platform device and automatic alignment method thereof

An alignment platform and automatic alignment technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as workpiece alignment deviation and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

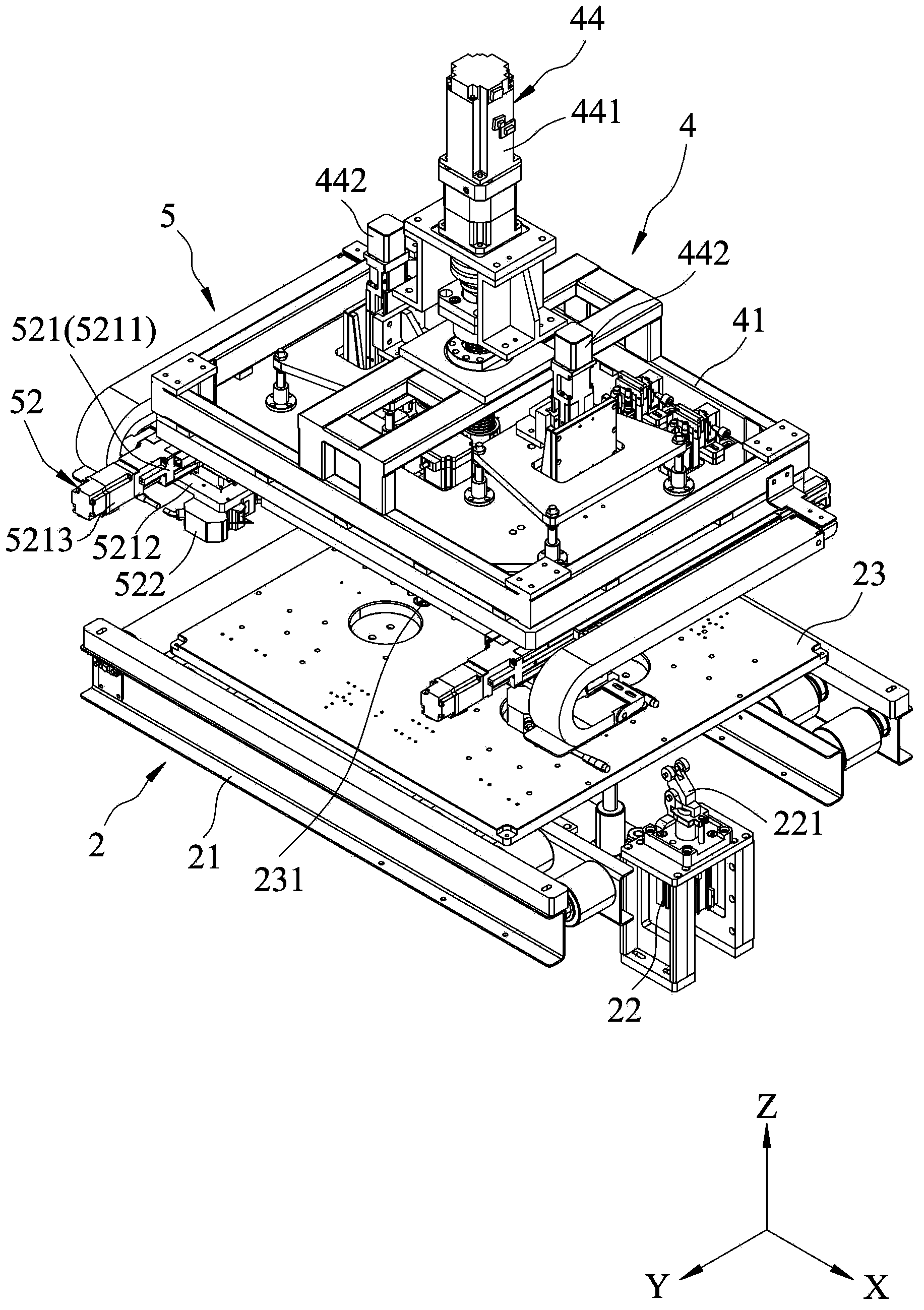

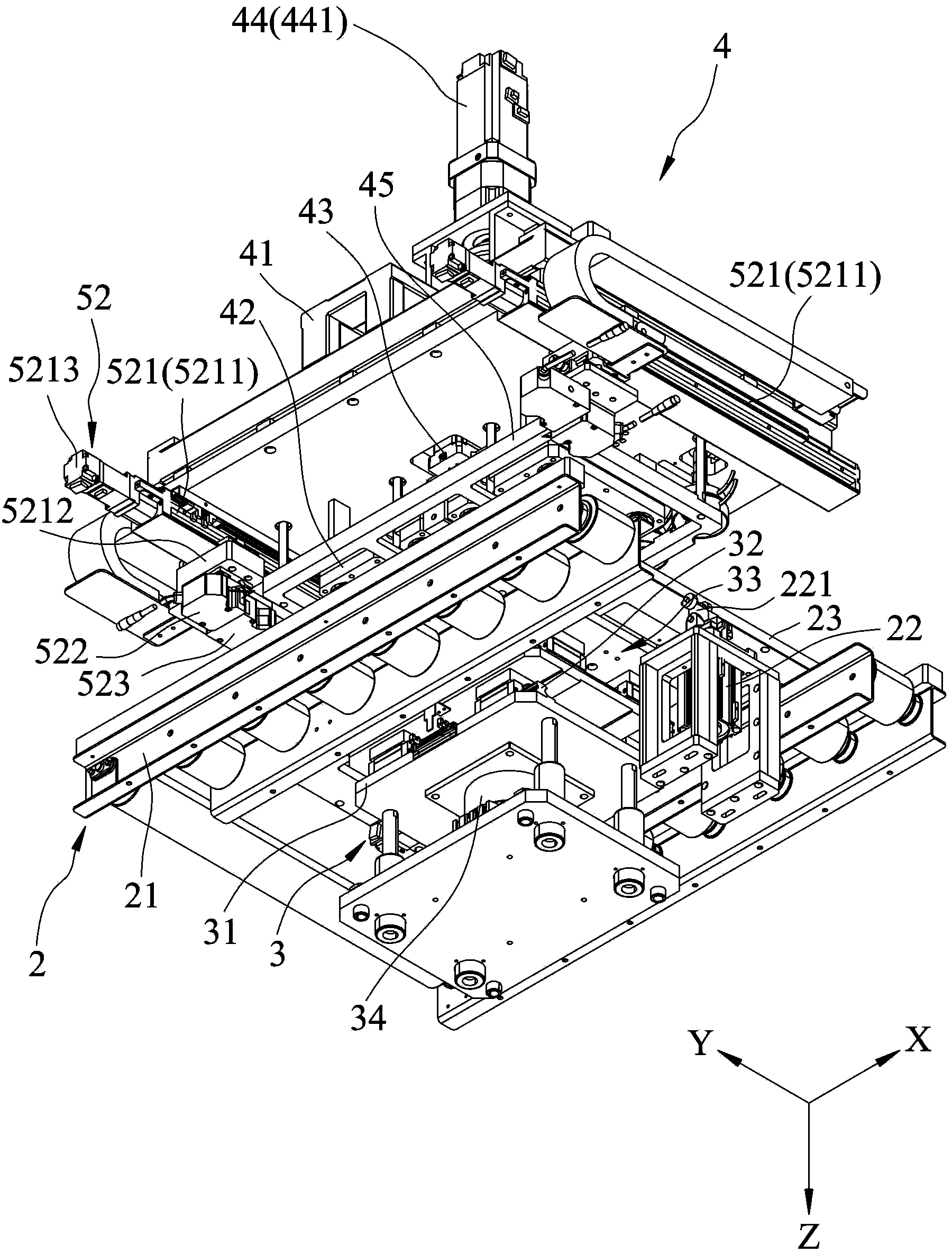

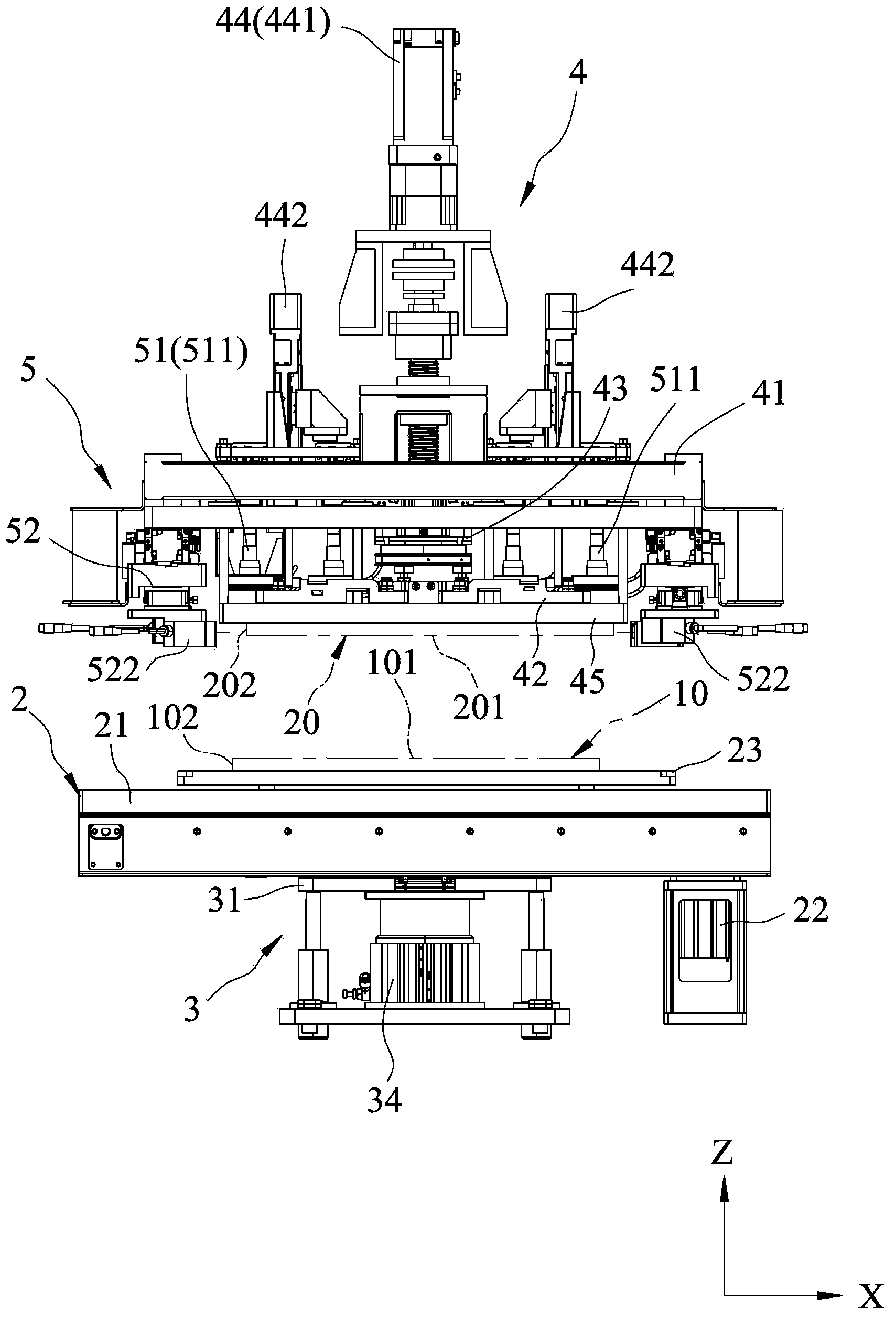

[0035] refer to figure 1 , figure 2 , image 3 ,and Figure 8 , a preferred embodiment of the transmission line automatic lifting alignment platform device of the present invention is suitable for aligning and pressing a first workpiece 10 and a second workpiece 20. The first workpiece 10 is rectangular and has two A first side 101 and two second sides 102, the second workpiece 20 is rectangular and has two first sides 201 and two second sides 202, and in this preferred embodiment, the The first workpiece 10 is, for example, a plastic or alloy casing, and the second workpiece 20 is, for example, a glass display module. The transmission line automatic jacking and positioning platform device includes a transmission unit 2 , a jacking carrier unit 3 , a lifting and pressing unit 4 , and an automatic positioning unit 5 .

[0036] The transport unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com