Glove-type abrasive paper with two sides capable of being used

A glove and one-sided technology, applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of changing the folding size of sandpaper, not easy to hold it in the hand, and inconvenient, so as to reduce waste and reduce the trouble of replacing sandpaper. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

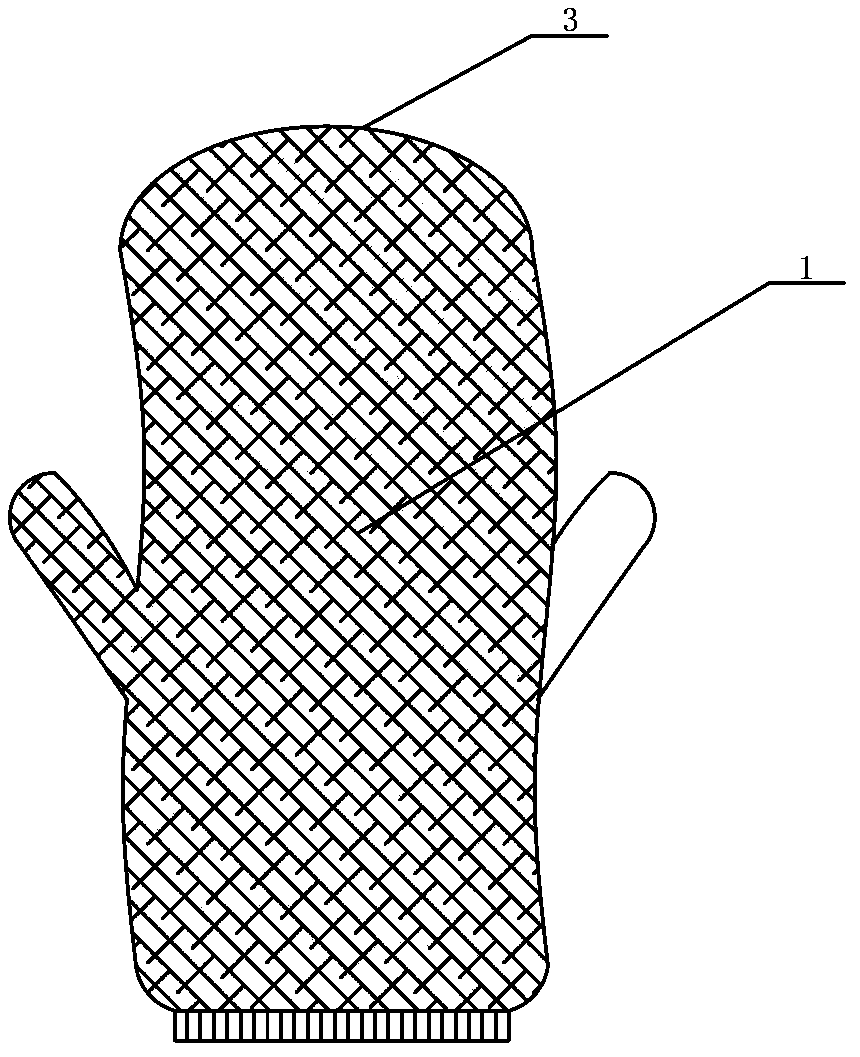

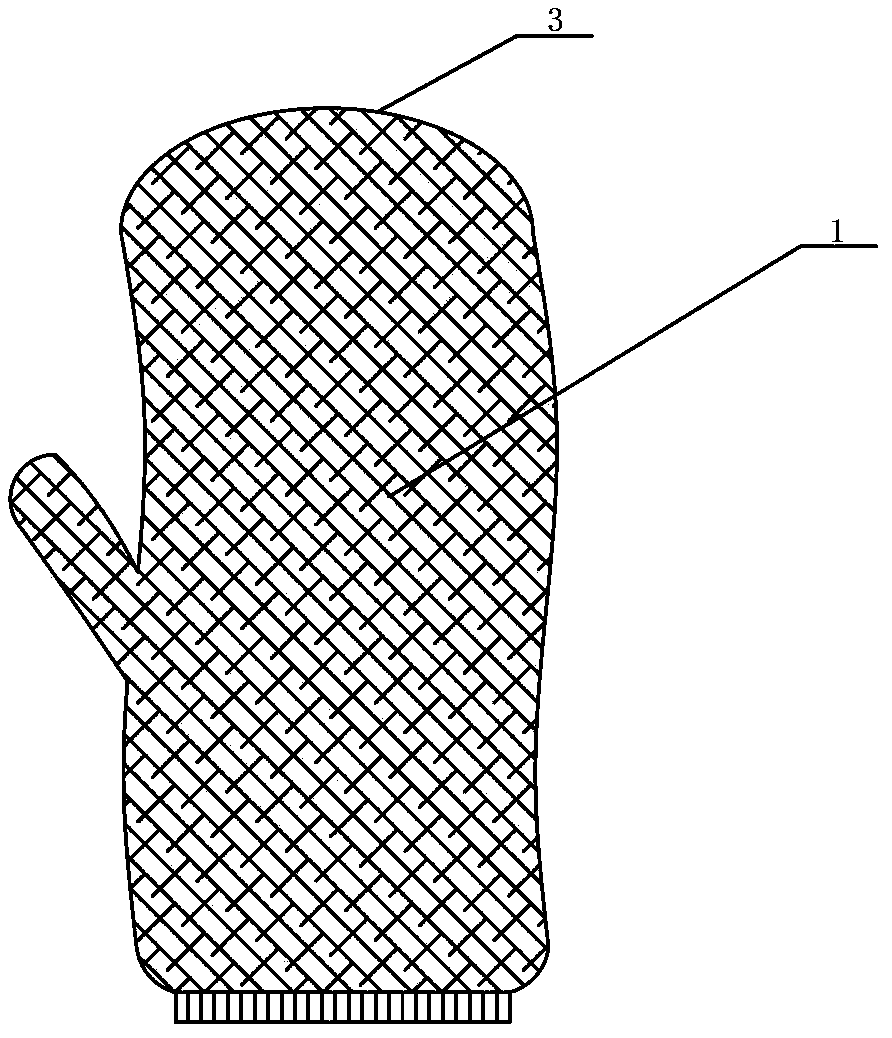

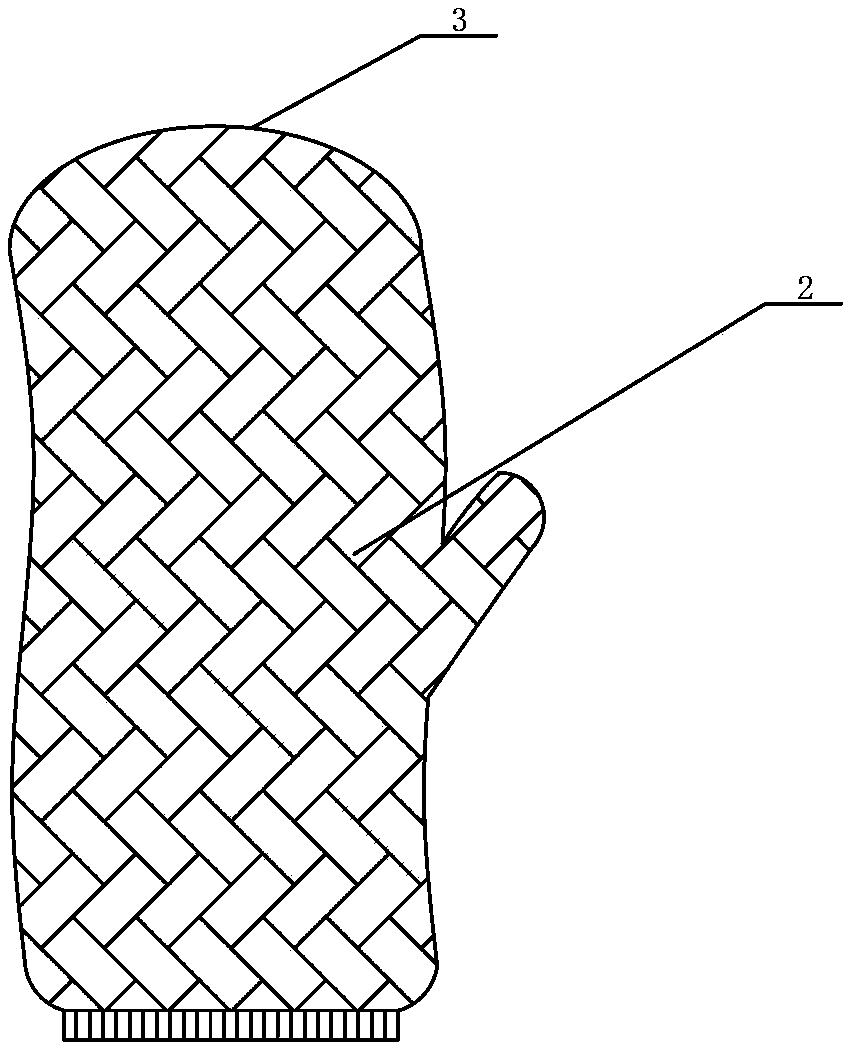

[0012] see Figure 1-3 , the specific embodiment adopts the following technical scheme: it comprises coarse sandpaper layer 1, fine sandpaper layer 2, glove body 3, coarse sandpaper layer 1 is arranged on one side of glove body 3, and fine sandpaper layer 2 is arranged on the other side of glove body 3 .

[0013] The coarse sandpaper layer 1 and the fine sandpaper layer 2 are cut according to the shape of the glove body 1 of the glove body 1, and after cutting, the coarse sandpaper layer 1 and the fine sandpaper layer 2 are respectively bonded to both sides of the glove body 3 with super glue That's it.

[0014] When this specific embodiment is in use, the object that needs to be processed can be processed. Since the sandpaper is close to the palm, it is easier to change the direction of friction. At the same time, the user can also easily adjust the strength of positive pressure to change the size of the friction surface. It can also be processed with sandpaper on the finge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com