Double-section type automobile spoiler

A spoiler and automobile technology, applied in the direction of car body, vehicle parts, streamlined body, etc., can solve the problems of high production process cost, insignificant effect, low production cost, etc., to improve quality performance, reduce the cost of mold opening, The effect of high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings.

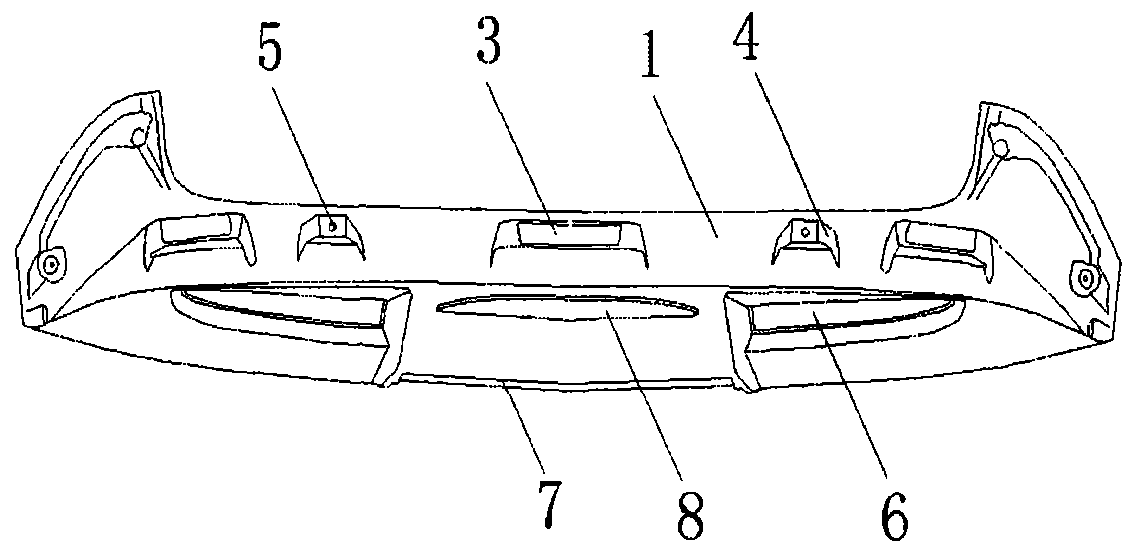

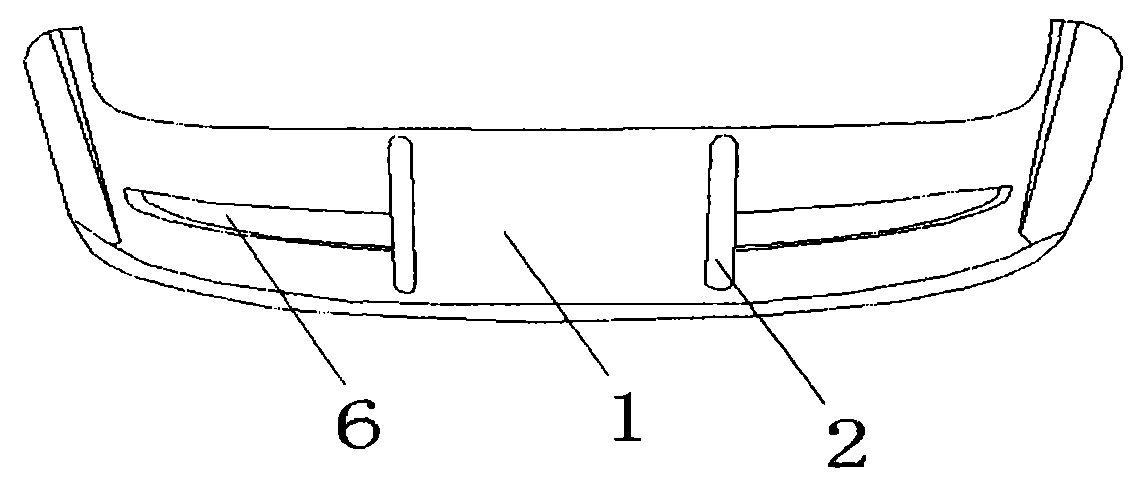

[0014] A two-stage automobile spoiler, comprising a spoiler body 1, reinforcing ribs 2, mounting slots 3, fixing blocks 4, fixing nuts 5, vent holes 6, lamp mounting grooves 7 and reinforcing grooves 8, its features The reason is: the spoiler body 1 is set in an arc-shaped structure, and is integrally formed by polymer ABS modified material, which not only improves the overall quality and performance of the spoiler, but also does not need to open multiple molds, which reduces the production cost. The reinforcing rib 2 is arranged on the front of the spoiler body 1 to further improve the strength of the spoiler, and the installation slot 3, the fixing block 4, and the reinforcing groove 8 are all arranged on the back of the spoiler body , the number of the installation slots 3 is 3, and the fixing nuts 5 are arranged on the fixing block 4. When the double-stage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com