Damping device for traverse guide rod of spinning machine

The technology of a damping device and a yarn guide rod is applied to the spinning machine, the open-end spinning machine, the spinning machine with continuous winding, etc. The problem of unbalanced operation of the yarn guide mechanism can achieve the effect of reducing inertia, improving molding quality and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

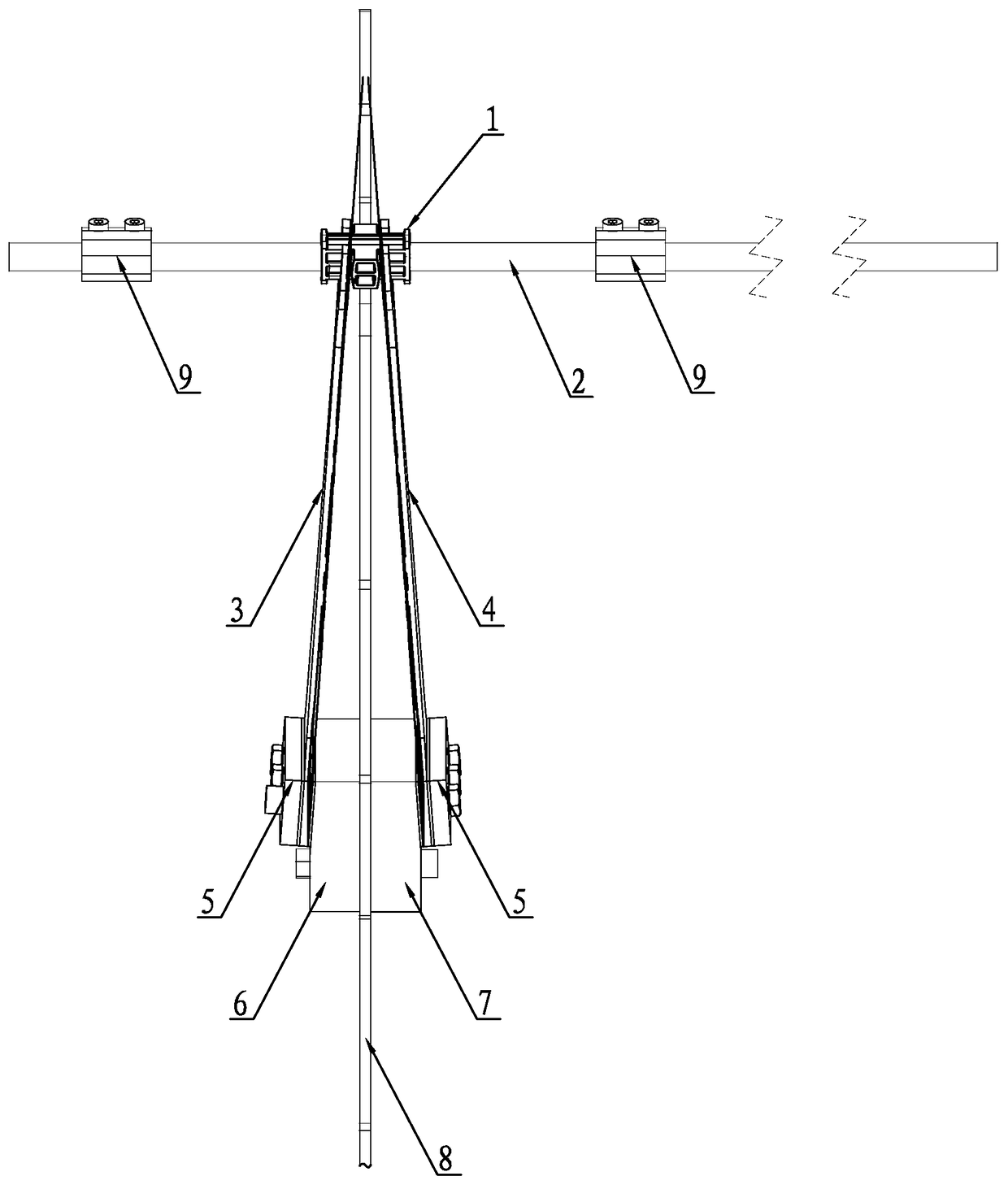

[0012] A spinning machine traverse guide bar damping device, such as figure 1 As shown: it consists of yarn guide rod damping block 1, yarn guide rod 2, damping left spring piece 3, damping right spring piece 4, pressure plate 5, elastic adjustment block 6, base plate 7, impact block 8 and fastener 9 , the yarn guide rod damping block 1 is provided with a sliding through hole, the yarn guide rod damping block 1 is set on the yarn guide rod 2 through the sliding through hole, and there is a gap between the sliding through hole and the outer diameter of the yarn guide rod 2 Cooperate, the two ends of the yarn guide rod damping block 1 are provided with an axial clamping groove, and the upper ends of the damping left spring piece 3 and the damping right spring piece 4 are symmetrically stuck in the axial clamping groove of the yarn guide rod damping block 1 , the collision block 8 is fixedly installed on the sliding limit position of the yarn guide rod 2, the yarn guide rod dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com