Clamping type air inflation connector

An inflatable joint and clip-on technology, which is applied in the field of clip-on inflatable joints, can solve the problems of poor bonding effect between gas nozzles, air leakage, and insufficient direct operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

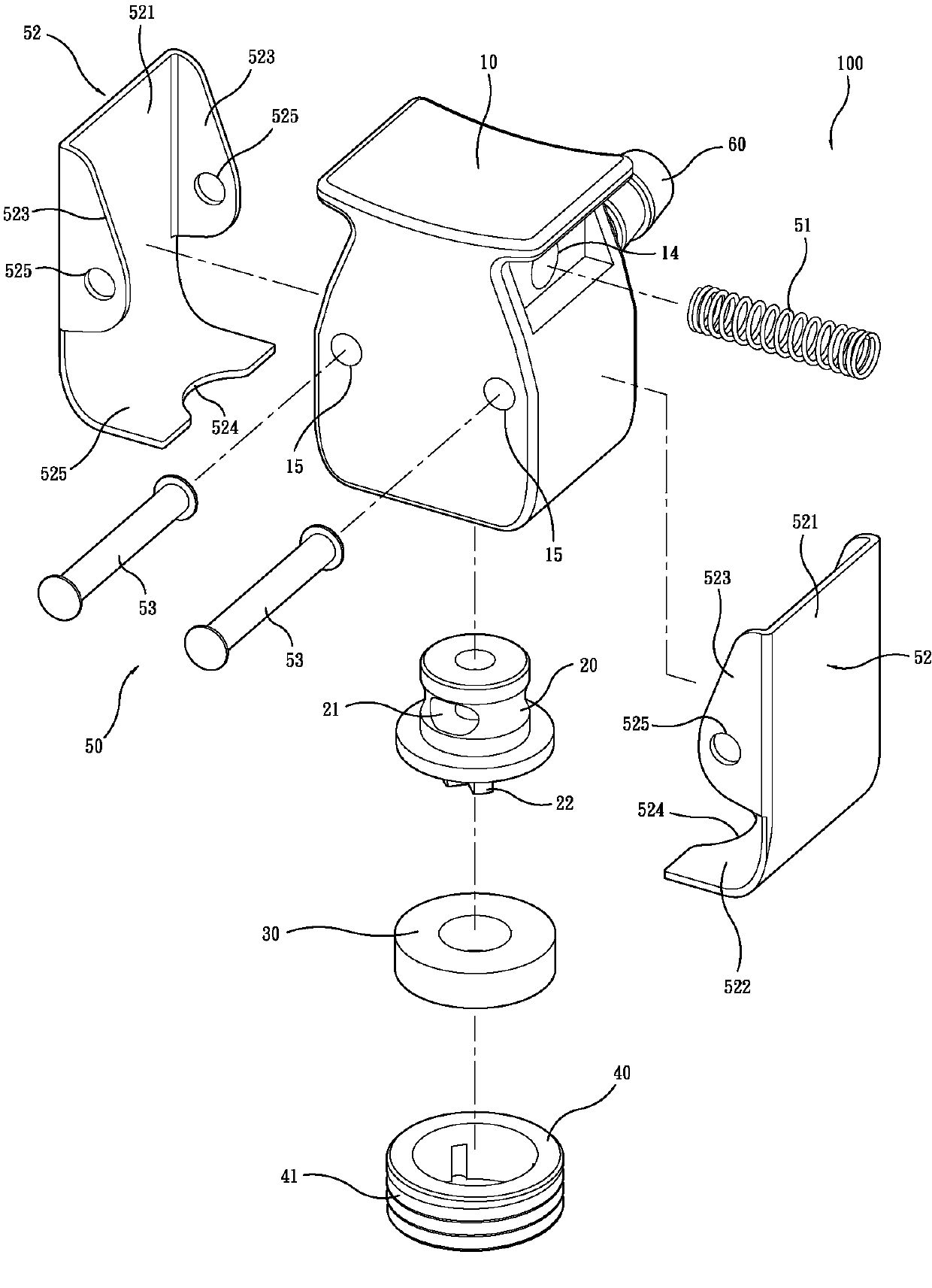

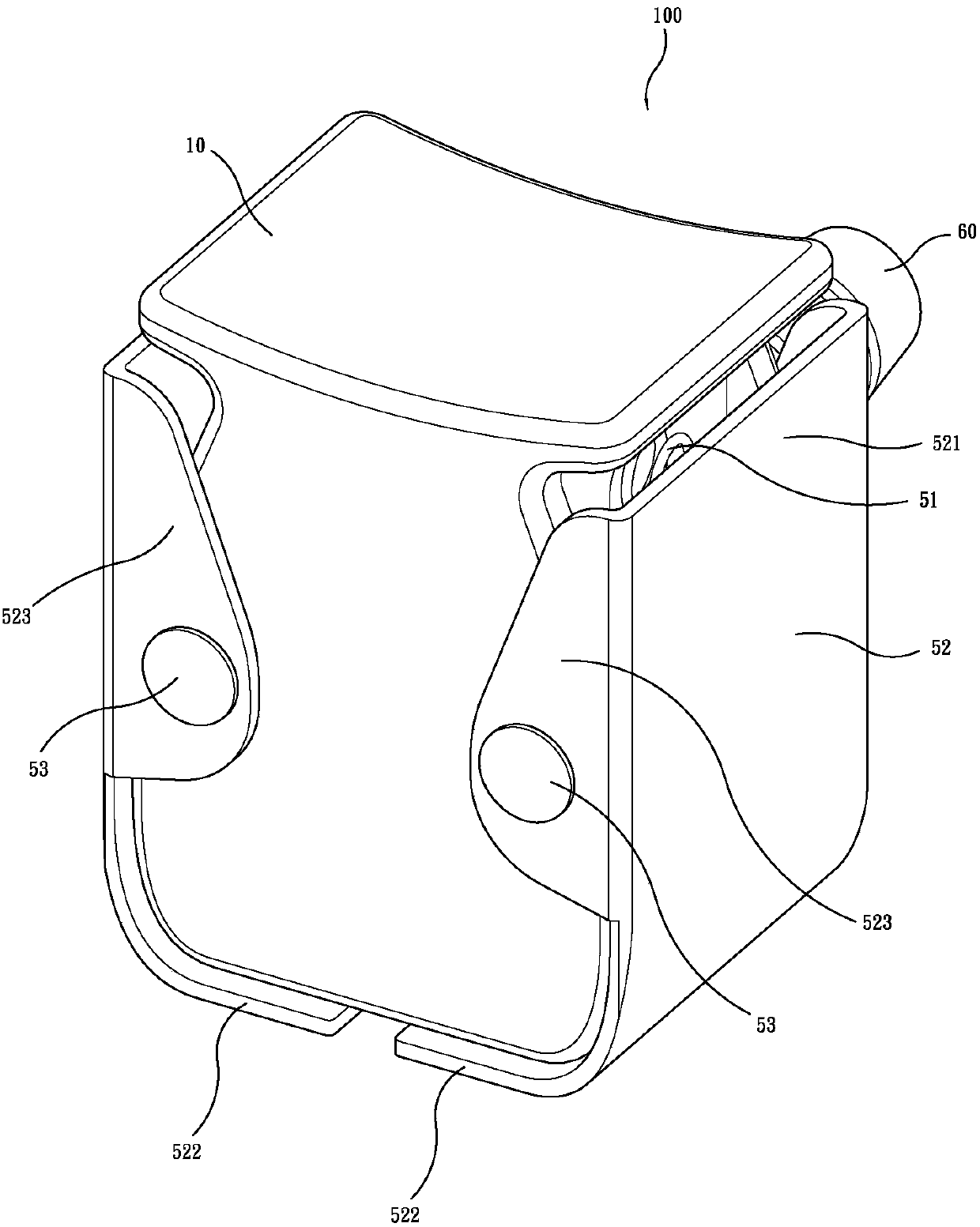

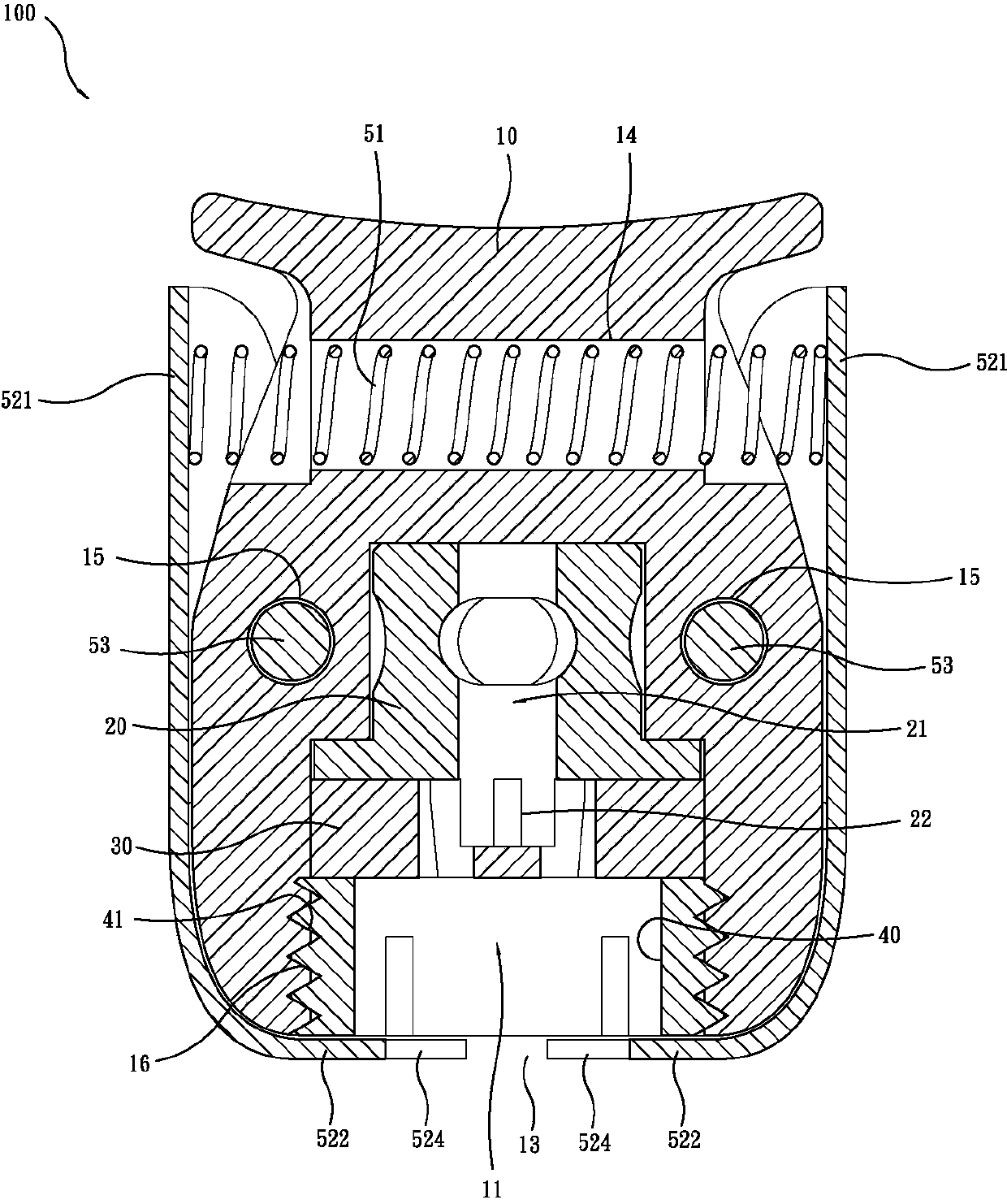

[0043] see Figure 1 to Figure 6 , the clip-type inflatable joint 100 of a preferred embodiment provided by the present invention mainly includes a joint main body 10, a pressure injector 20, an air-tight ring 30, a limit ring 40 and a clamping component 50, wherein :

[0044] see Figure 1 to Figure 6 , the joint main body 10 has an inflatable flow channel 11 inside, and an input port 12 connecting the inflatable flow channel 11 to the outside on one side of the joint main body 10, and the bottom side end of the joint main body 10 has a Connecting the inflation channel 11 to the output port 13 of the outside world, the two opposite sides of the joint main body 10 have a through hole 14 passing through each other, and the other two opposite sides of the joint main body 10 have a pivot hole 15 passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com