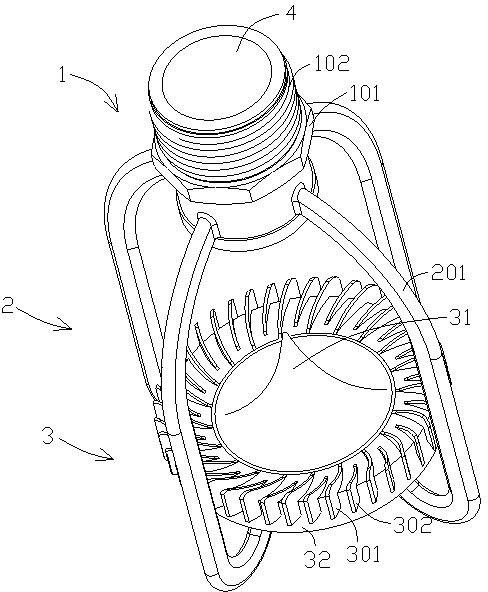

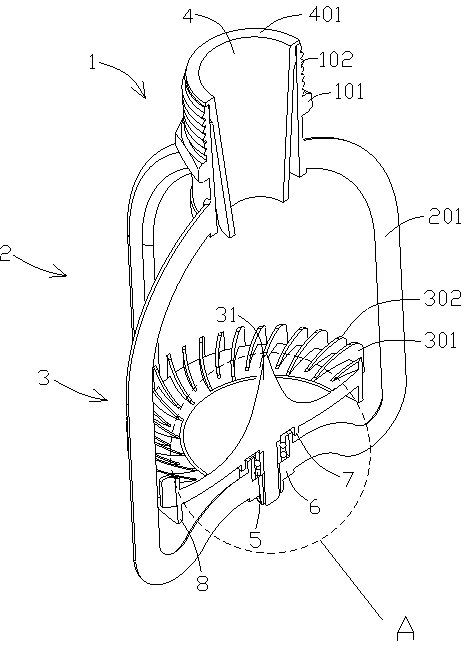

Rotary type energy-saving sprinkler for cooling tower

A spray device and rotary technology, applied in the field of cooling towers, can solve the problems of uneven spray water droplets and small spray range, and achieve the effect of large spray range, good effect and uniform spray water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

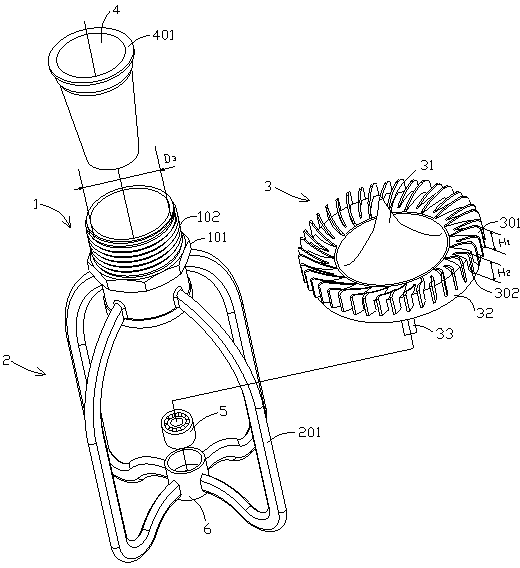

[0052] Such as Figure 6 As shown, the rotary sprinkler device of the present invention is described on the basis of the blade shape shown in the figure. As shown in the figure, the upper surface of the turntable 3 is horizontal, and no arc-shaped raised portion 32 is provided at its edge. The first vane 301 and the second vane 302 have the same shape, only different in size, and they are all in the shape of an arc that gradually rises from the side close to the tapered protrusion 31 to the side away from the tapered protrusion 31, that is, the inner side of the blade and the side of the second vane 302. The bottom surfaces of the tapered protrusions 31 (the upper surface of the turntable 3 ) are in contact. Moreover, one end of the blade (including the first blade 301 and the second blade 302 ) is not bent along the horizontal direction relative to the other end, that is, the blade is straight along the length direction. In addition, the conical round pipe 4 is not installe...

Embodiment 6-9

[0058] The parameters corresponding to Embodiments 6-9 in Table 2 are used as the basic parameters of this embodiment. The parameter definition is the same as above.

[0059] Table 2: Parameter table of cooling tower rotary energy-saving sprinkler device

[0060] Example 6 Example 7 Example 8 Example 9 D. 1 (cm) 100 100 100 100 D. 2 (cm) 70 70 70 70 N (pieces) 40 66 68 42 h 3 (cm) 40 40 40 40 h 1 (cm) 14 14 14 14 h 2 (cm) 10 10 10 10 D. 3 (cm) 30 30 30 30

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com