Method for dynamically measuring width of steel billet by using laser displacement sensors

A technology of laser displacement and sensors, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as huge investment, low cost performance, and complicated technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

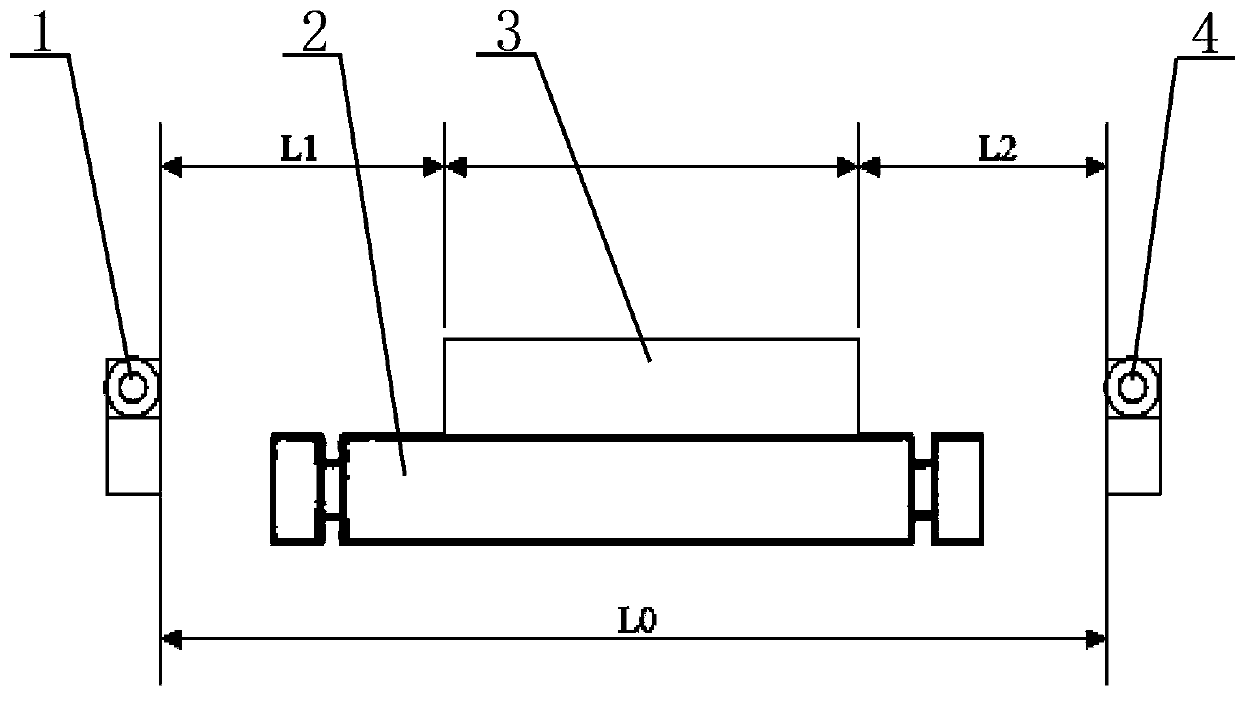

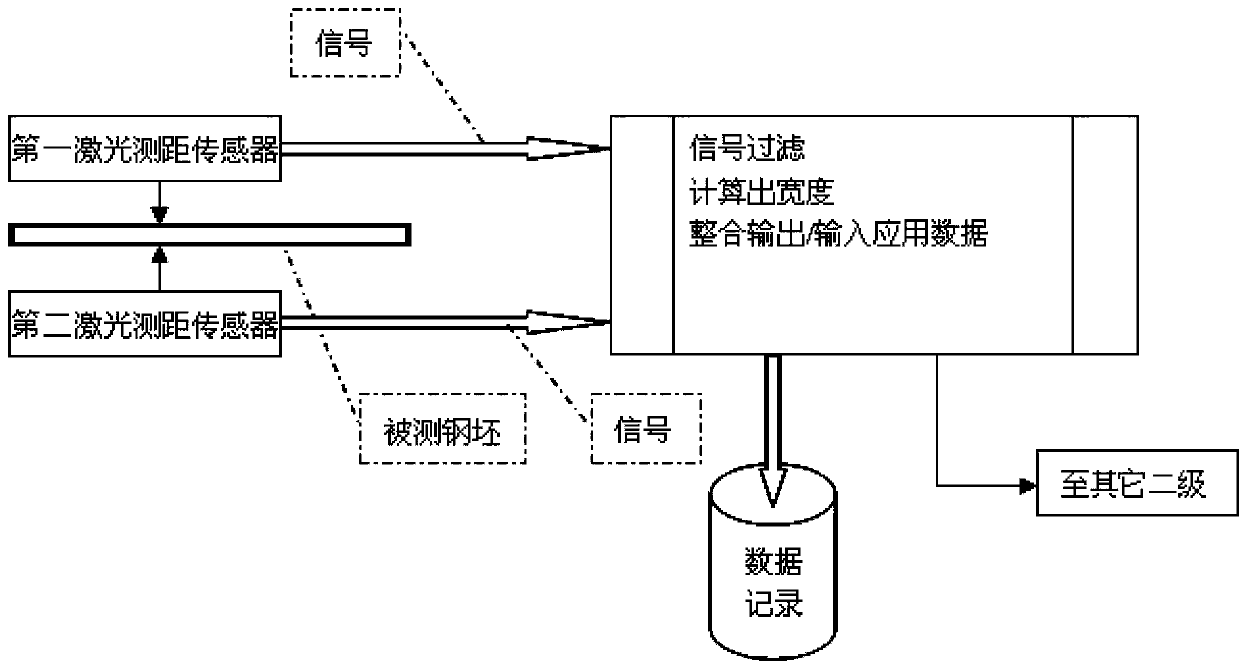

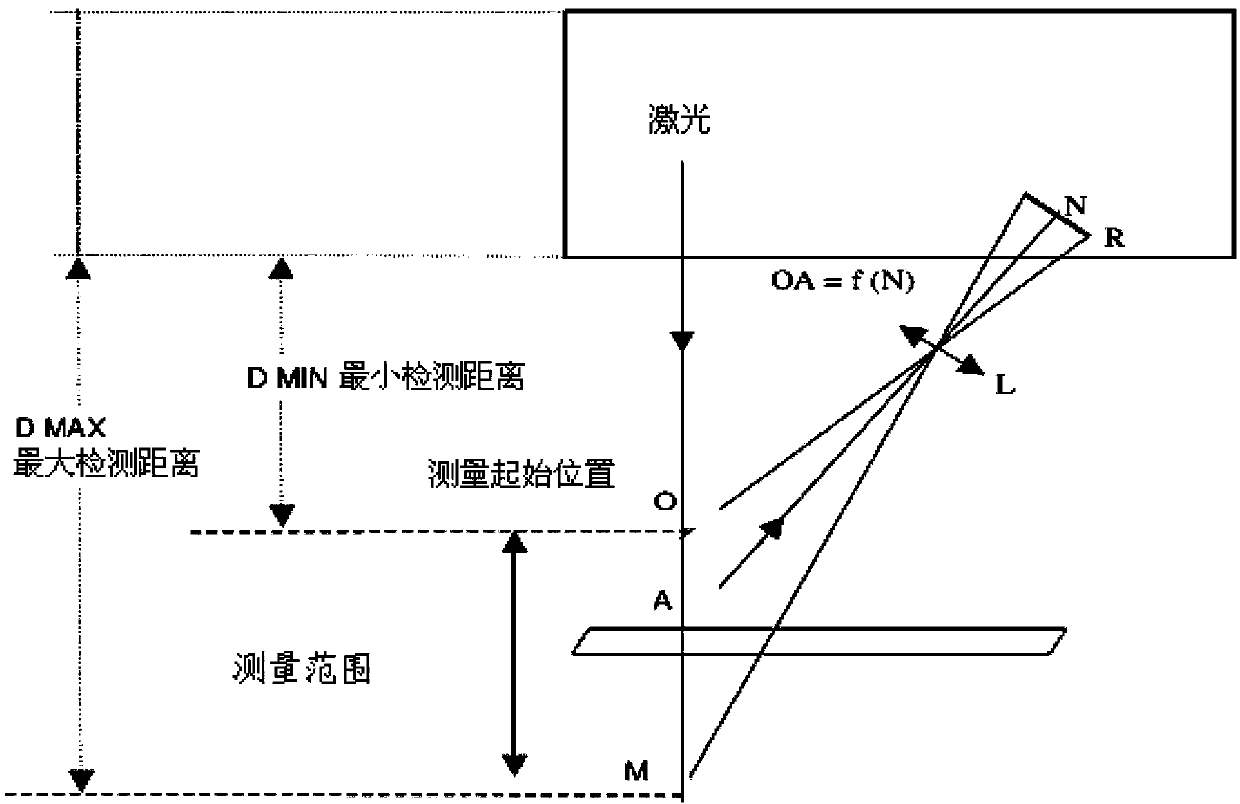

[0009] A method for dynamically measuring billet width using a laser displacement sensor such as figure 1 , figure 2 As shown, the characteristics of the method steps are: ① using an optical triangulation device including two laser displacement sensors, installing the two laser displacement sensors on both sides of the roller table 2 before the billet 3 is purged, and the two laser displacement sensors The laser emitting end of the displacement sensor faces the side wall surface of the steel billet 3, and the camera is used to shoot the steel billet 3 currently moving on the roller table 2 and the video signal captured in real time is synchronously transmitted to the industrial control computer. When the steel billet 3 passes through the two When the position between the two laser displacement sensors, the distance between the first laser displacement sensor 1 and the side of the steel billet 3 measured by the optical triangulation is L1, and the second laser displacement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com