An in-situ monitoring method for steel bar corrosion and stress state in concrete

A technology of stress state and inner steel bars, which is applied in the field of durability of reinforced concrete structures, corrosion monitoring and durability evaluation of reinforced concrete structures, can solve the problems of inability to judge the corrosion state of steel bars, few test data, and validity to be confirmed, etc., to achieve The effect of solving the problem of steel corrosion monitoring, the structural design is exquisite and reasonable, and the design principle is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

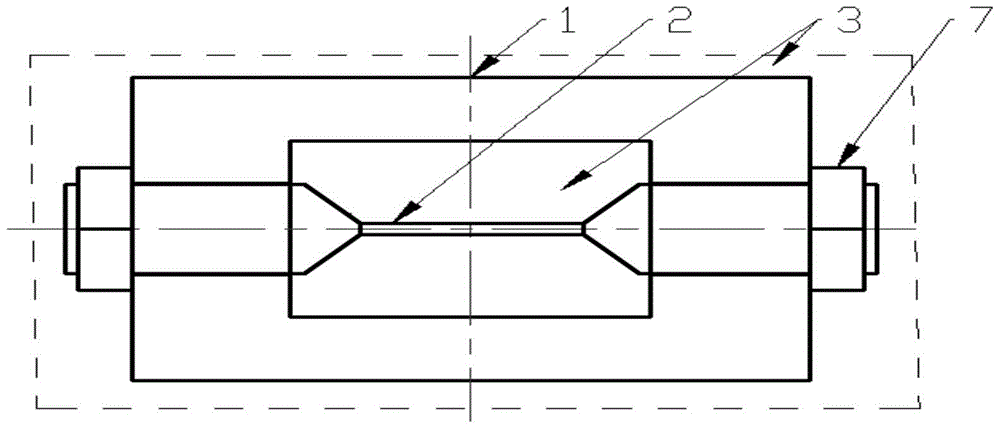

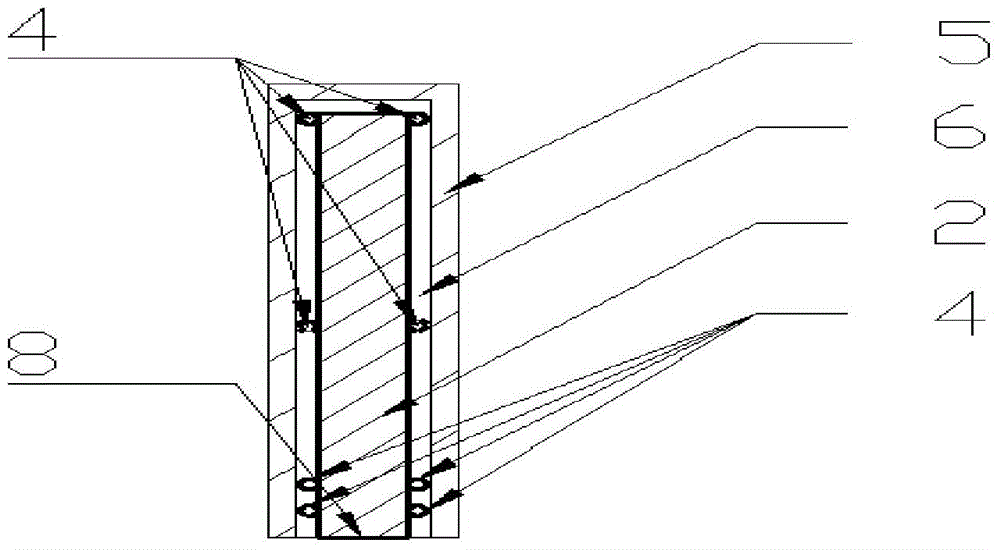

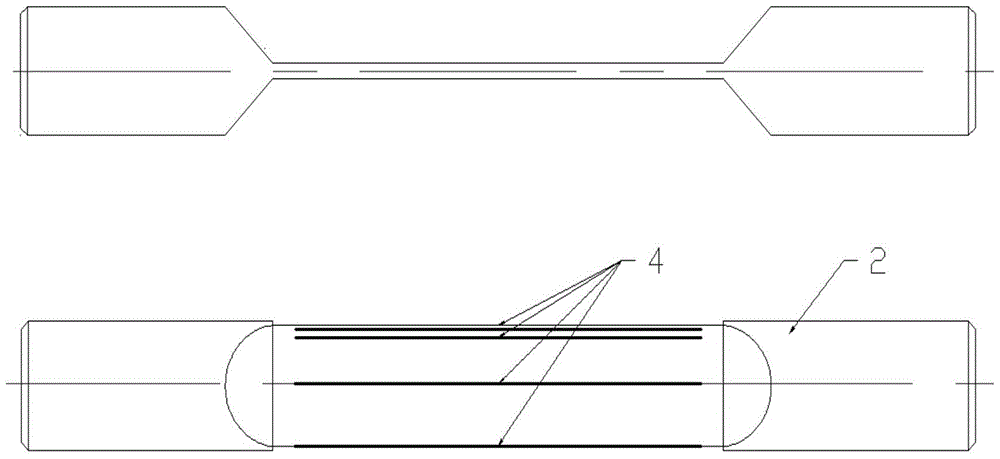

[0022] The steel bar corrosion sensor structure of the present invention is as shown in Figure 1, and wherein middle steel bar sheet 2 adopts the same material as the longitudinally stressed steel bar in the concrete structure, and continuous strain measuring points 4 are arranged at different heights on the middle steel bar sheet 2 section ( Figure 1b , Figure 1c As shown), the distributed continuous strain measuring point 4 adopts high-spatial-resolution distributed optical fiber, which is pasted at different heights of the steel sheet section by high-performance glue, and is connected to the corresponding demodulator through the transmission optical fiber, and the high-spatial-resolution distributed optical fiber Can continuously monitor the length direction ( Figure 1c Shown) the average strain per millimeter of length, reserve a section of optical fiber close to the loading nut that is not attached to the steel wire sheet (not deformed together with the sheet), and is ...

Embodiment 2

[0023] Embodiment 2: the structure of the present invention is as shown in Figure 1, and wherein middle steel bar sheet 2 adopts the same material as the longitudinally stressed steel bar in the concrete structure, and continuous strain measuring points 4 are arranged at different heights on the middle steel bar sheet ( Figure 1b , Figure 1cshown), continuous strain measuring point 4 adopts a chain strain gauge group (such as HBM KY11-1 / 120), each chain strain gauge group has 10 measuring gauges, and 1 temperature compensation gauge is used for temperature compensation (below The monitored strain is the strain after compensation), the grid length of a single strain gauge is 0.6mm, and the center distance between adjacent strain gauges is 1mm. It is pasted on different cross-sectional heights of the steel bar sheet with high-performance glue. The strain gauge is connected to the strain gauge through welding terminals and wires. The chain strain gauge group can continuously mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com