Optical socket and optical module with such optical socket

An optical socket and optical fiber technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of reduced optical information transmission efficiency, poor coupling efficiency, inability to improve the installation strength of the photoelectric conversion device 8, etc., and achieve excellent optical characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described.

[0037] However, where the basic structure is the same as or similar to that of the prior art, the same symbols are used for description.

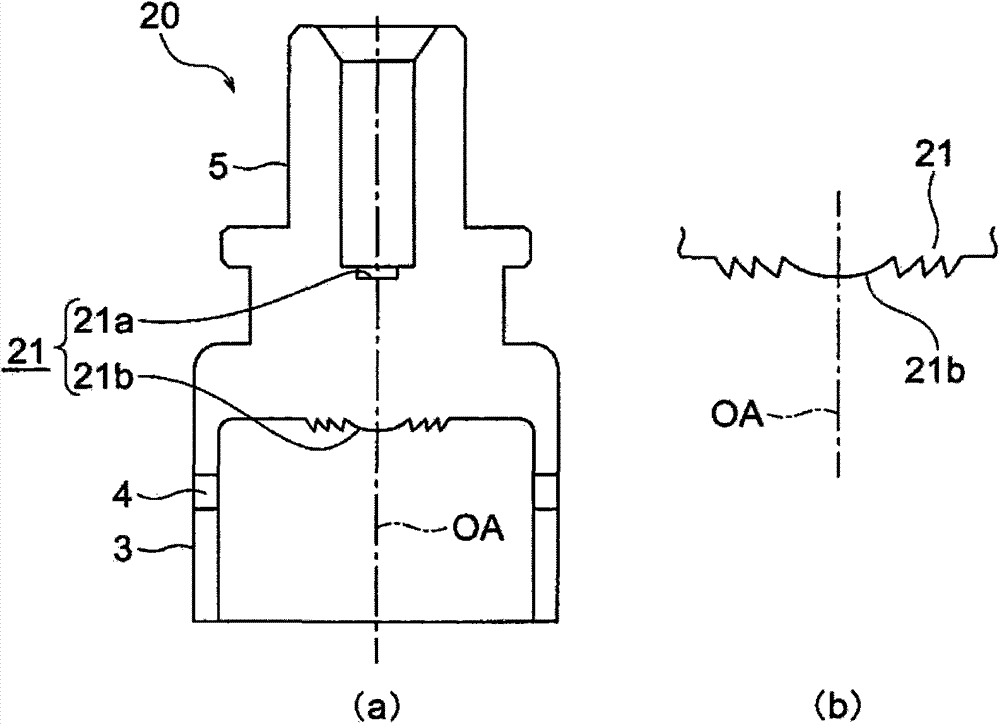

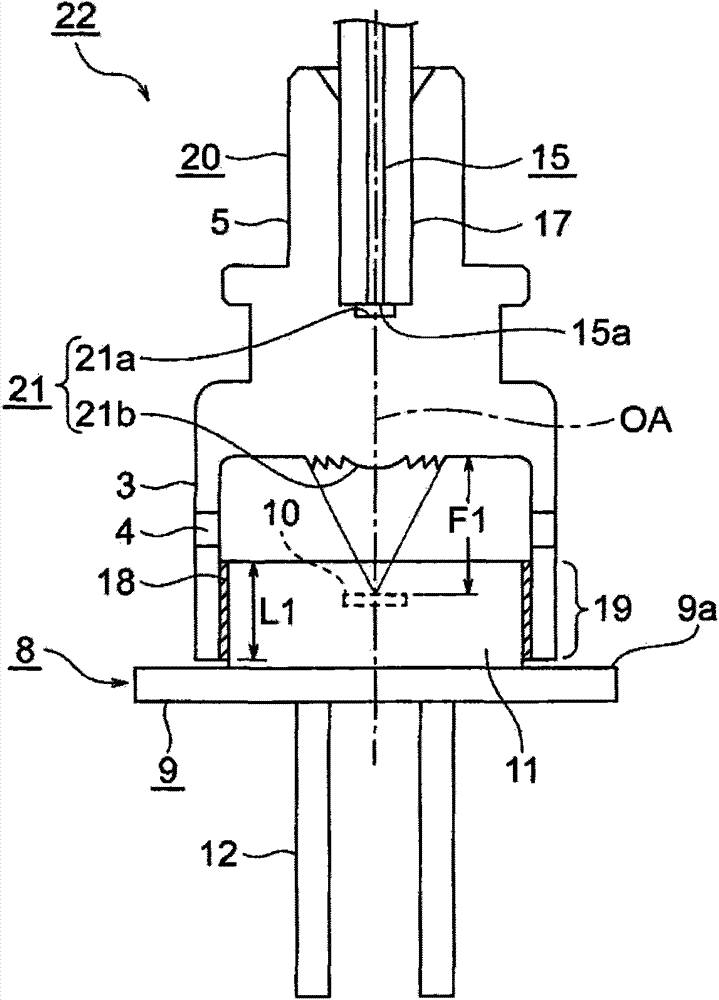

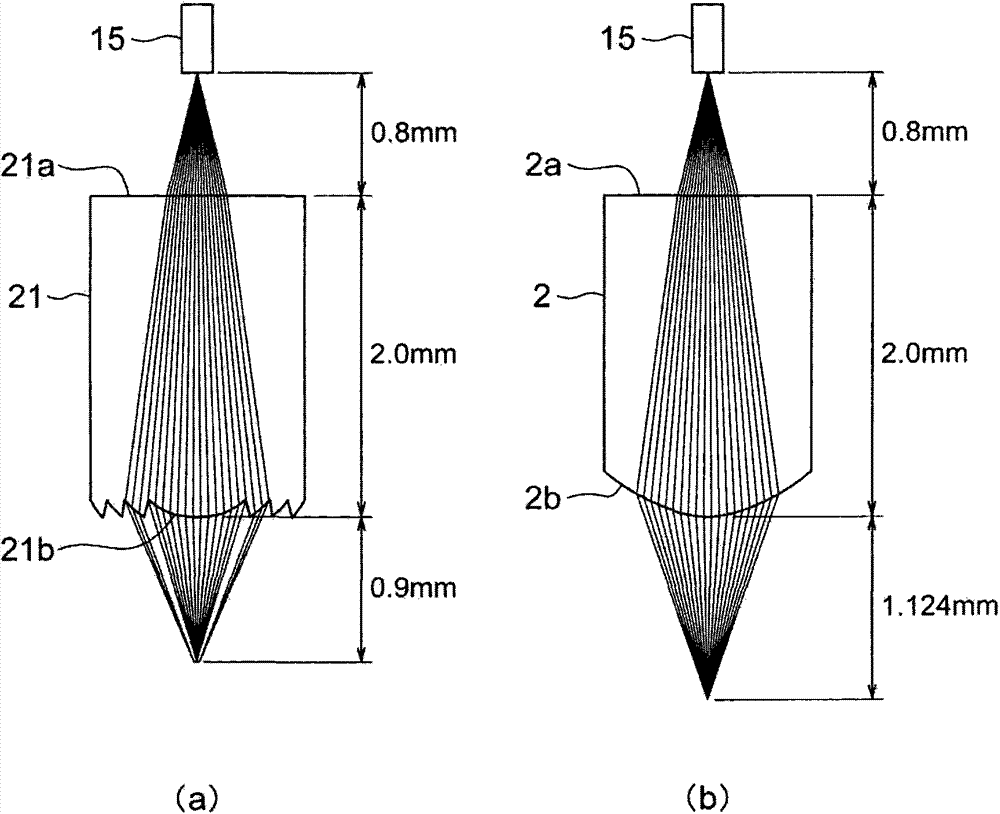

[0038] Such as figure 1 as well as figure 2As shown, optical receptacle 20 in this embodiment is configured by integrally forming lens 21 , photoelectric conversion device mounting portion 3 , and optical fiber mounting portion 5 using a translucent resin material like conventional optical receptacle 1 . In addition, the optical receptacle 20 in this embodiment is different from the conventional example in that the lens 21 is formed as a Fresnel lens having a convex surface on the second surface 21 b facing the light receiving element 10 .

[0039] For further clarification, in Figure 6 In the existing structure shown in , the lens 2 is formed on the upstream side of the light in the direction of its optical axis OA ( Figure 6 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com