Carbon heater with mobile quartz tube

A carbon heater and quartz tube technology, which is applied to furnace heating elements and other directions, can solve the problems of rising production costs and declining product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention will be described in detail through preferred embodiments with reference to the accompanying drawings. The embodiment and the accompanying drawings are only for helping the understanding of the present invention, rather than limiting the technical scope of the present invention.

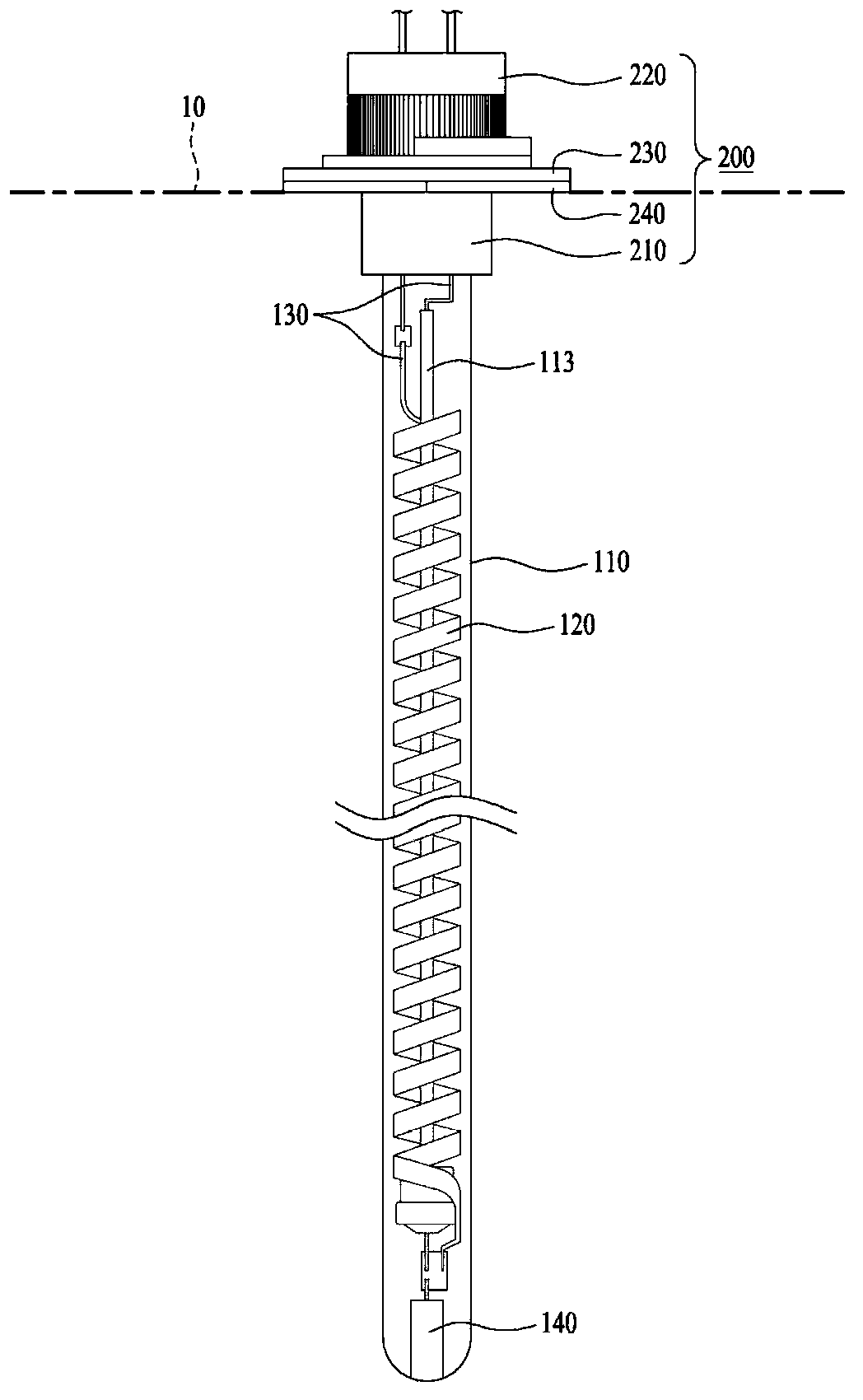

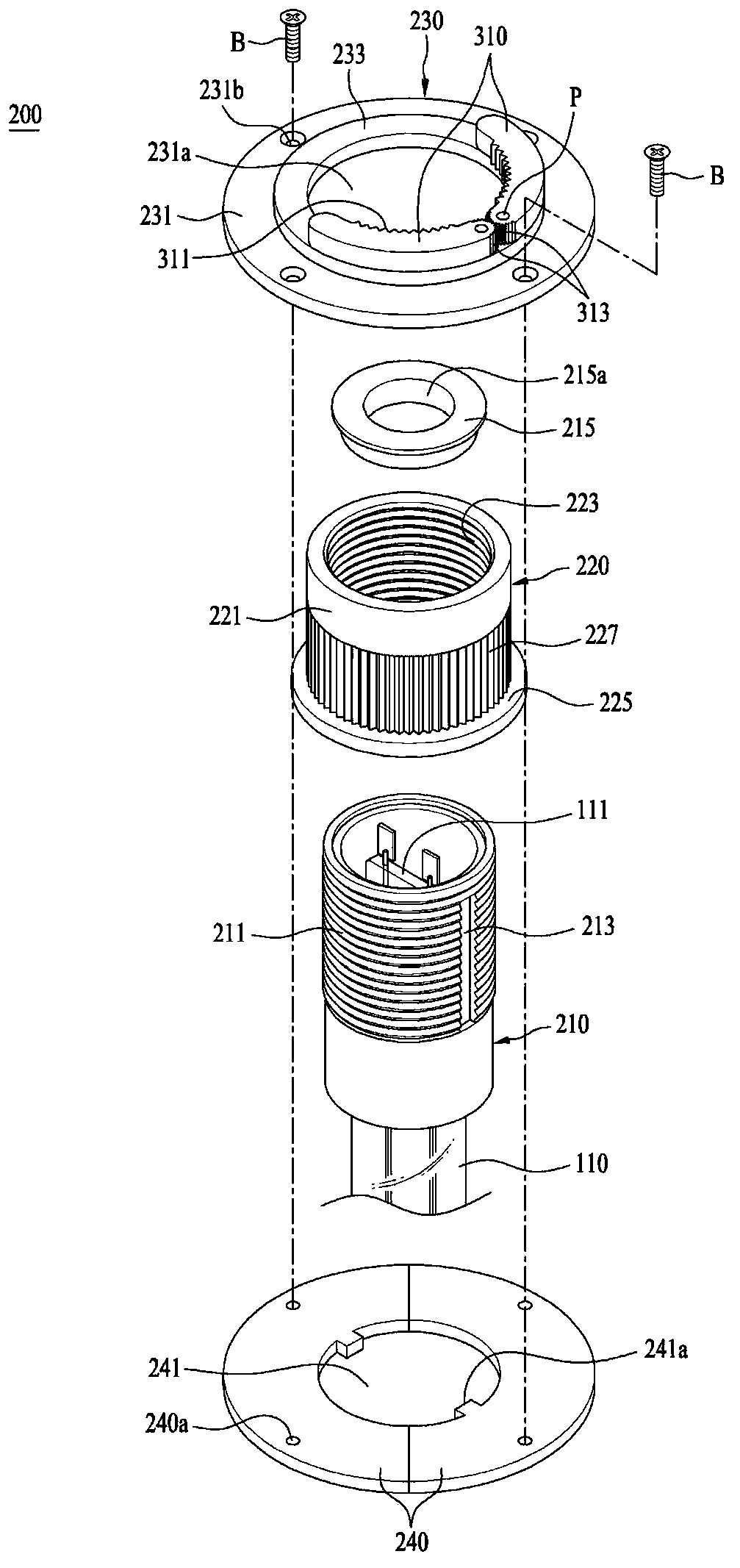

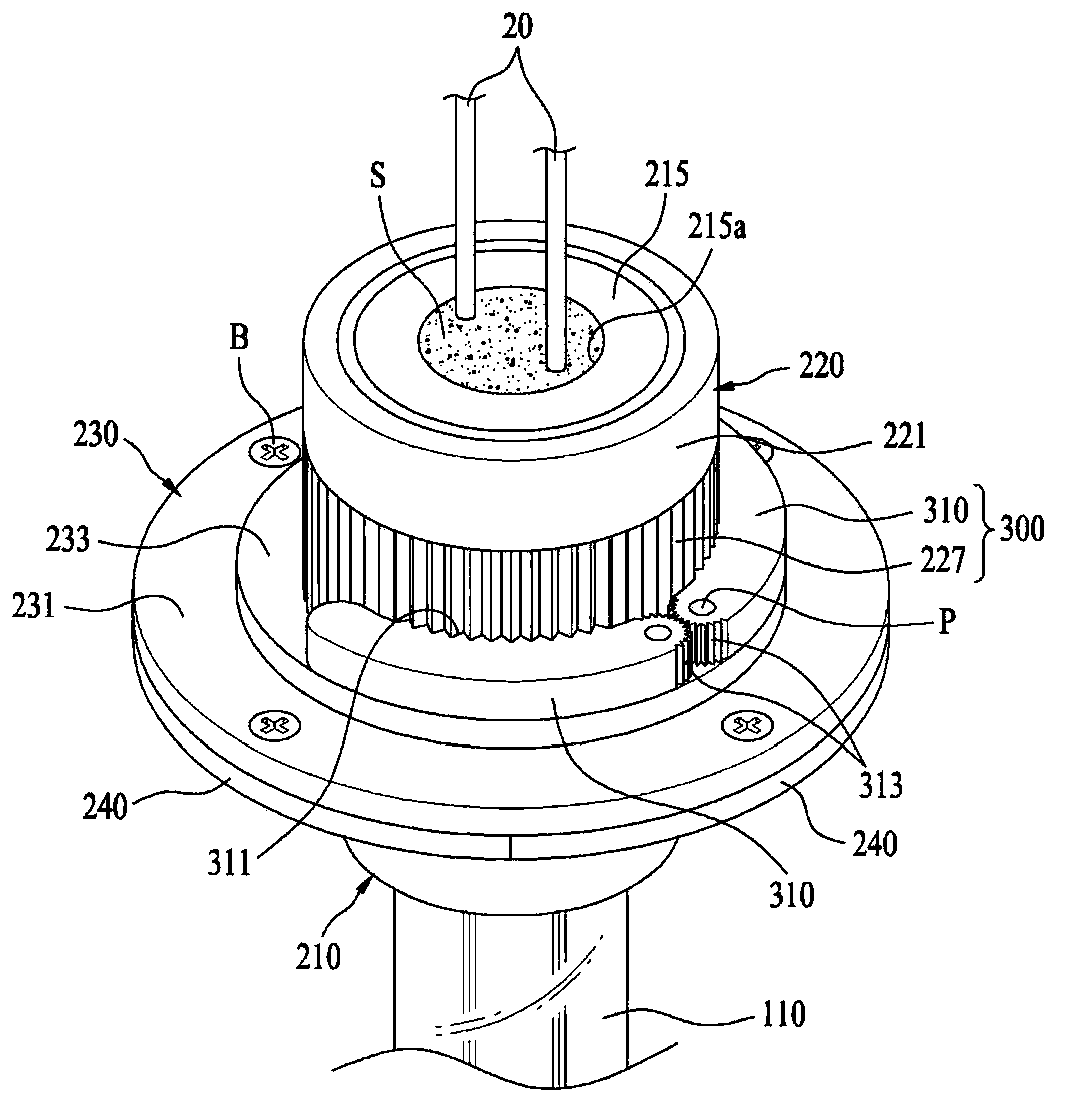

[0045] figure 1 It is a front view showing the carbon heater of the present invention, figure 2It is an exploded perspective view that disassembles the moving mechanism disposed on one side of the carbon heater in the structure of the carbon heater of the present invention, image 3 yes means figure 2 The perspective view of the main part of the bonded state, Figure 4 as image 3 The cross-sectional view of the main part of is a figure showing the state where the carbon heater of the present invention is installed on the storage part to be supplied with water, Figure 5 It is a perspective view of main parts showing a state in which the fixing mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com