Elevation-type hedge trimmer

A technology of hedge trimming and hedge trimming machine, which is applied in the direction of hedge trimming equipment, etc., can solve the problems of hedge trimmers that are difficult to trim and level off, and achieve the effect of simple structure, easy manufacture, and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

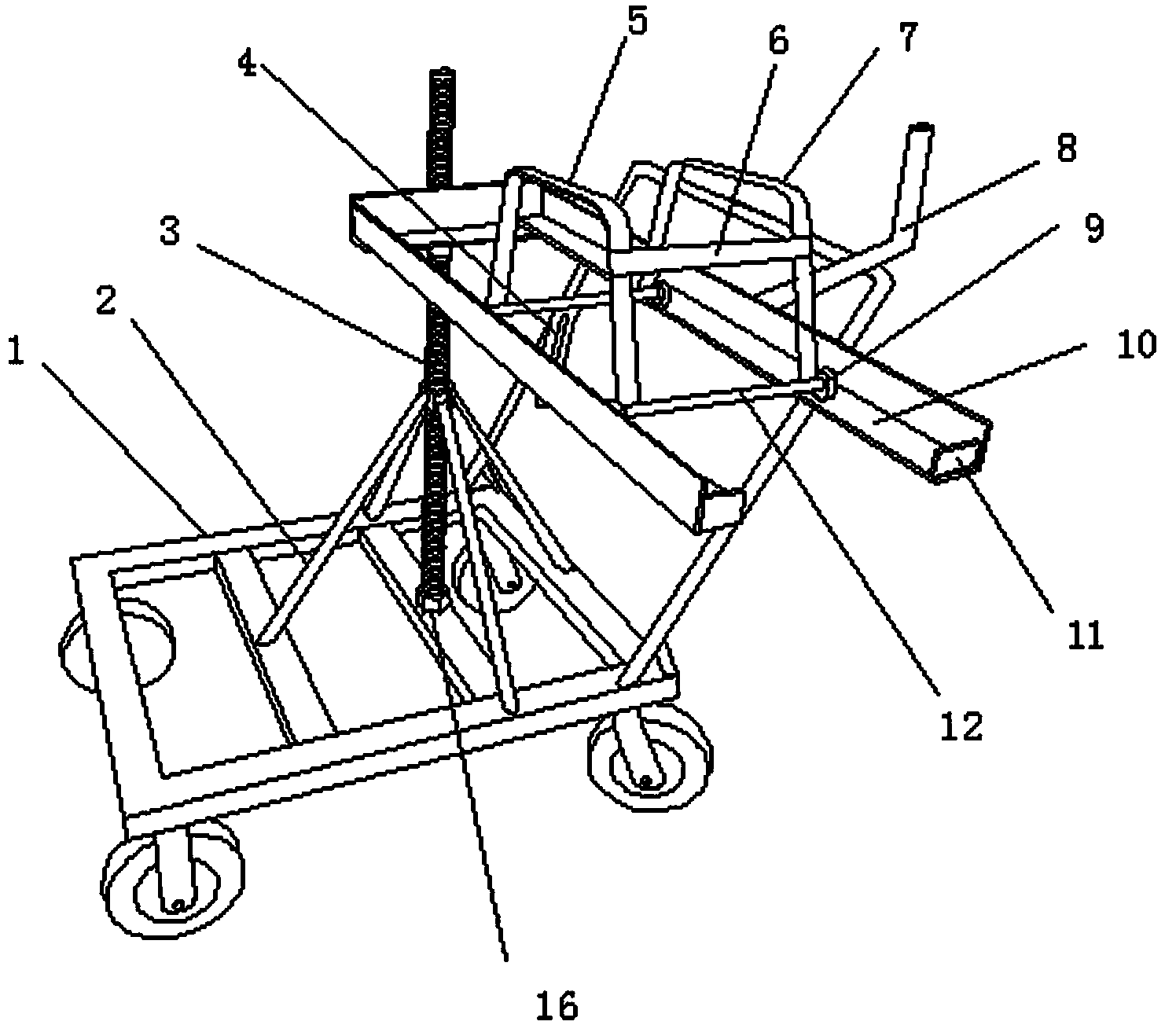

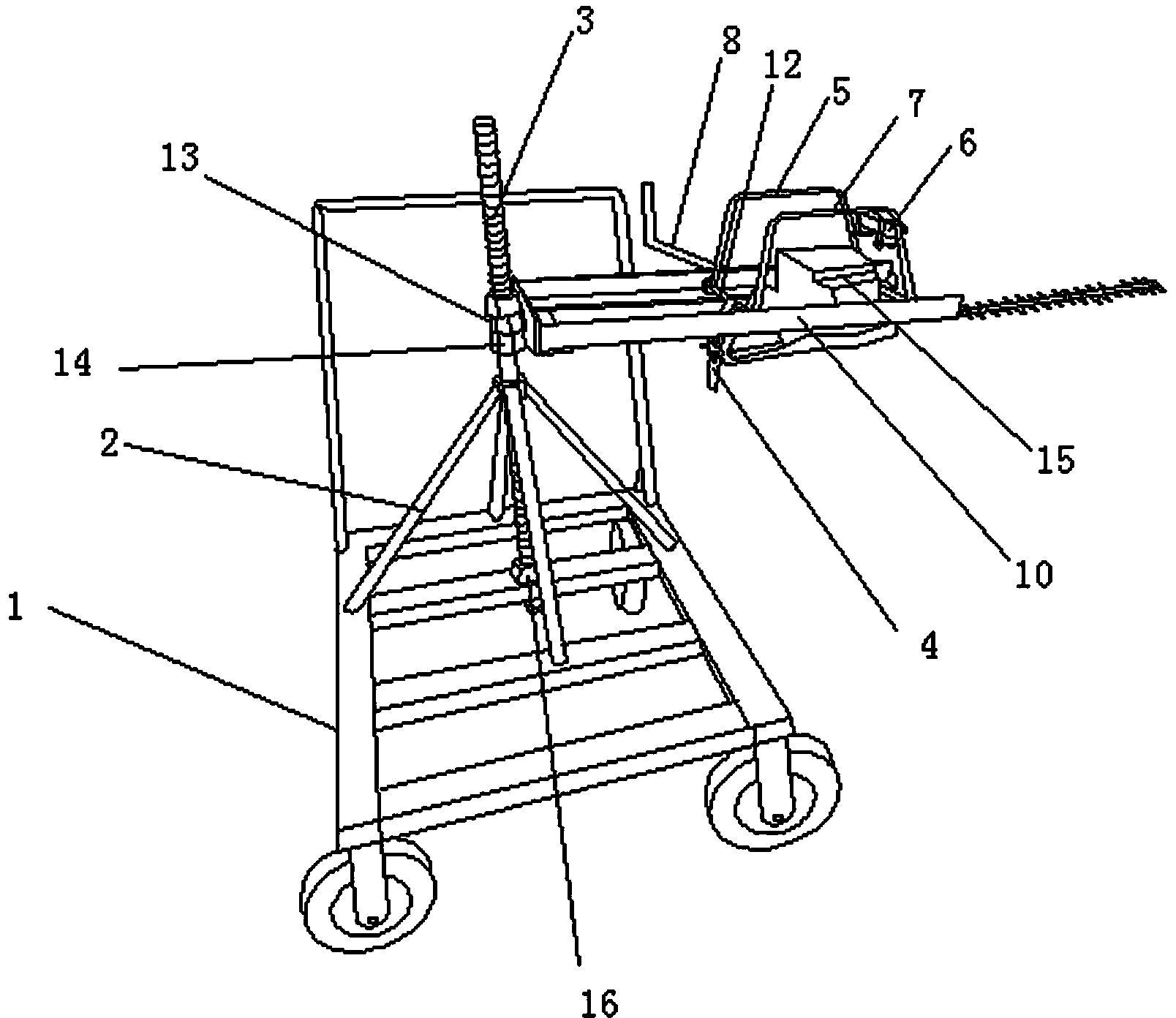

Method used

Image

Examples

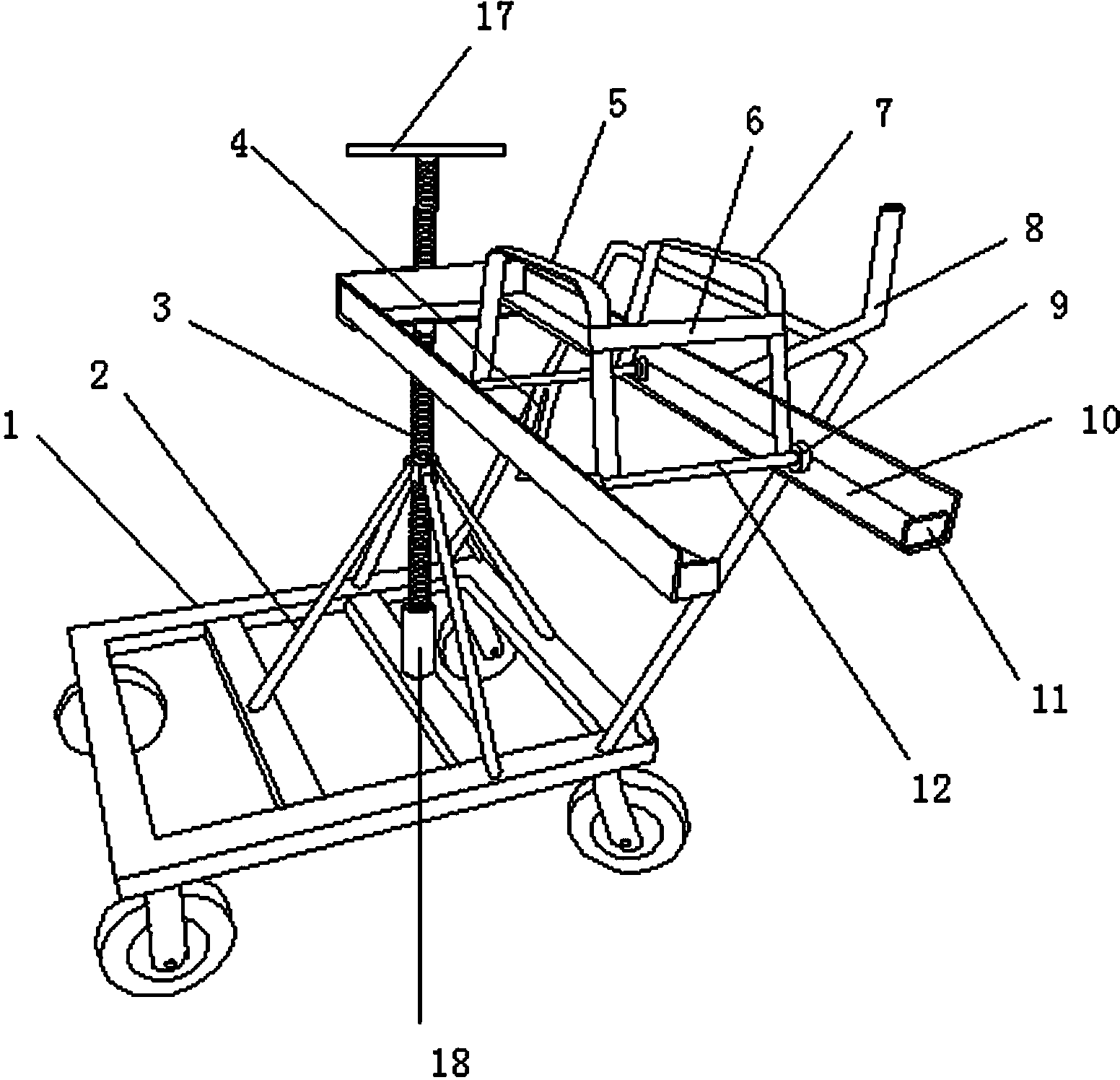

Embodiment 2

[0032] see image 3 , in the second embodiment, the rotation matching structure of the rotating slideway 10 and the lead screw 3 of the lead screw type lifting mechanism is that the rotating slideway 10 is fixed on the nut that is threadedly matched with the lead screw 3, and the top end of the lead screw 3 is provided with There is a handle 17 , when the handle 17 is rotated, the lead screw 3 moves up and down, and the hedge trimmer 15 can be adjusted to a suitable height.

[0033] In this embodiment, the height of the hedge trimmer 15 is adjusted by rotating the lead screw 3 to move the lead screw 3 up or down.

[0034] When the greener uses it, first adjust the rotary slide 10 to the height that needs to be trimmed, and then fix the hedge trimmer 15 to the cross bar 6 and the bent plate 4 of the sliding device 7 with U-bolts, push the cart 1 and control the Armrest 8, which can be rotated flexibly for far and near trimming operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com