Poultry farming device

A technology for poultry and poultry houses, which is applied in poultry cages or houses, poultry industry, applications, etc., can solve the problems of difficulty in meeting demand, inconvenient management, poor taste, etc., and achieve the effect of promoting growth and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

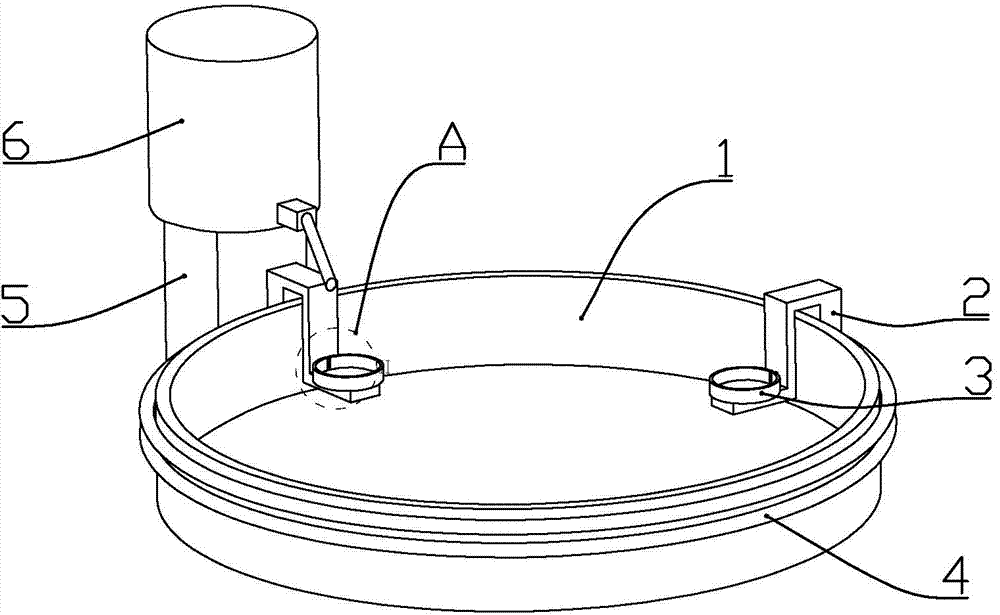

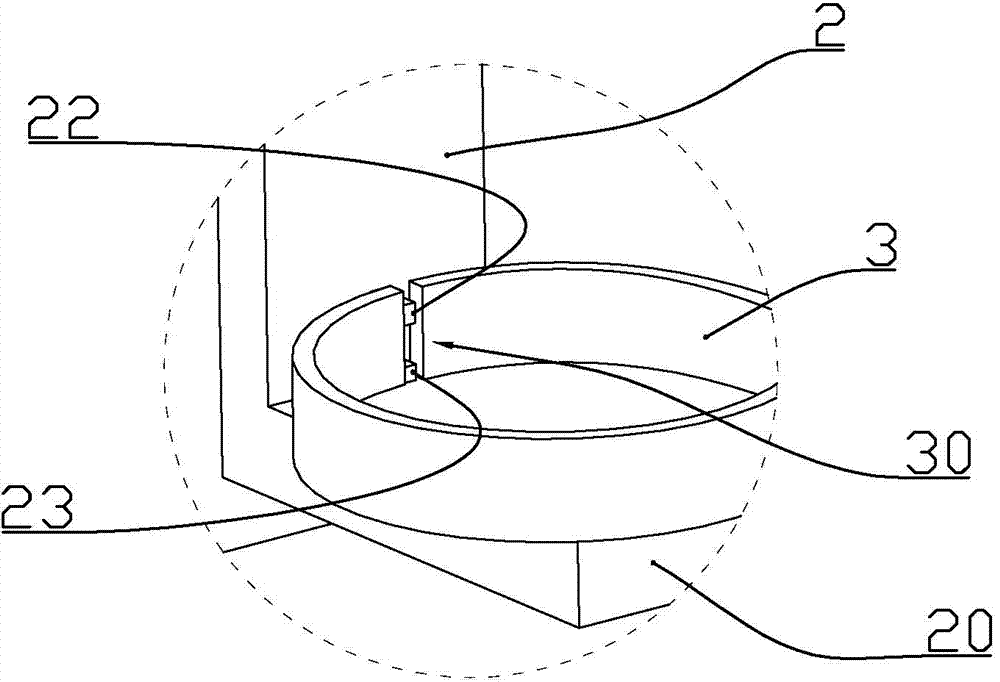

[0018] according to Figure 1 to Figure 4 As shown, a kind of poultry raising device described in this embodiment includes a circular trough-shaped poultry house 1, the radius of the poultry house is 1.5m-2.5m, and the height is 0.6m-1.2m. There are two coaxially arranged circular guide rails 4, on which one to three mobile frames 2 capable of moving along the guide rails are installed. One end of the inside is integrally connected with a supporting plate 20 arranged horizontally, and a feed pan 3 is installed on the supporting plate.

[0019] A motor 21 is installed in the moving frame 2 , and the output shaft of the motor is connected with a rubber wheel (not shown in the figure) that cooperates with the guide rail. The rubber wheels roll along the guide rail so that the mobile frame slides along the guide rail.

[0020] The two guide rails are connected with low-voltage electric wires lower than 36V. A first controller for controlling the rotation of the motor is installe...

Embodiment 2

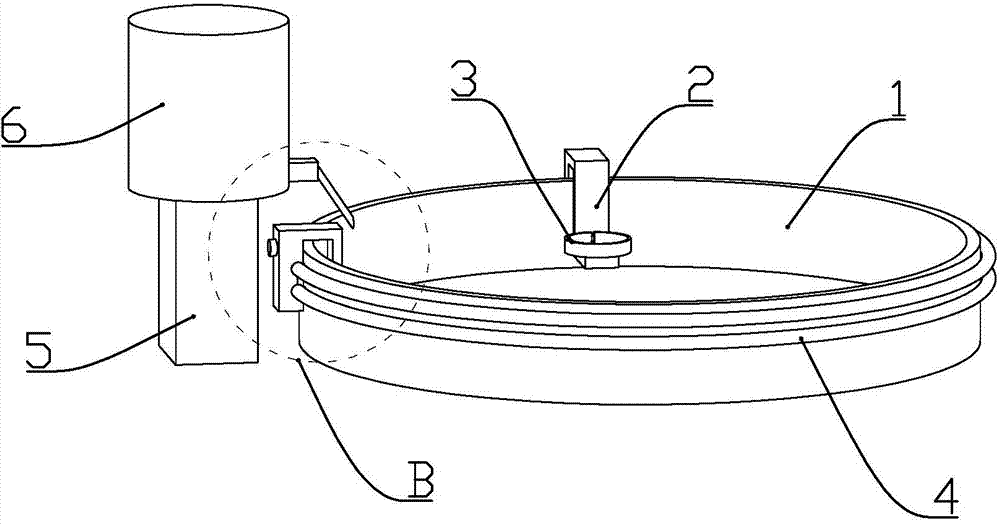

[0025] according to Figure 5 As shown, a kind of poultry raising device described in this embodiment includes a circular trough-shaped poultry house 1, the radius of the poultry house is 1.5m-2.5m, and the height is 0.6m-1.2m. There are two circular guide rails 4 arranged coaxially, and two mobile frames 2 that can move along the guide rails are installed on the guide rails. The entire mobile frame is U-shaped with the opening facing downwards. One end is integrally connected with a supporting plate 20 arranged horizontally, and a feed pan 3 is installed on the supporting plate.

[0026] A motor 21 is installed in the moving frame 2 , and the output shaft of the motor is connected with a rubber wheel (not shown in the figure) that cooperates with the guide rail. The rubber wheels roll along the guide rail so that the mobile frame slides along the guide rail.

[0027] The two guide rails are connected with low-voltage electric wires lower than 36V. A first controller for con...

Embodiment 3

[0032] according to Figure 6 As shown, a kind of poultry breeding system described in this embodiment includes a circular trough-shaped poultry house 1, the radius of the poultry house is 2m, and the height is 1m. Two circular guide rails 4 are installed on the periphery of the poultry house. One to three mobile frames 2 capable of moving along the guide rails are installed on the guide rails. The entire mobile frame is U-shaped with the opening facing downwards. One end of the mobile frame located in the poultry house is integrally connected with a horizontally arranged Supporting plate 20, a feed pan is installed on the supporting plate.

[0033] A motor 21 is installed in the moving frame 2 , and the output shaft of the motor is connected with a rubber wheel (not shown in the figure) that cooperates with the guide rail. The rubber wheels roll along the guide rail so that the mobile frame slides along the guide rail.

[0034] The bottom of the pallet is connected with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com