Mandril-cooling device of wood-plastic extrusion die

A technology for extrusion dies and cooling devices, applied in the field of extrusion dies, can solve problems affecting the cooling effect of mandrels, affecting the quality of extruded products, and leakage of cooling water, and achieves easy removal of scale, good sealing, and quick disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

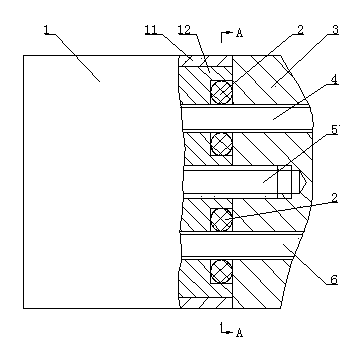

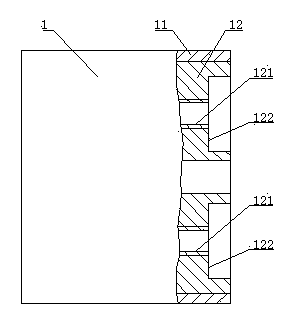

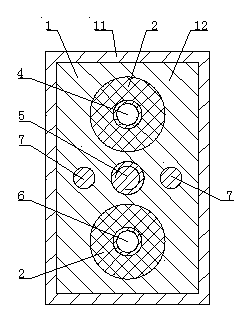

[0009] see Figure 1 to Figure 3 , the present invention includes a tail mandrel 1, a front mandrel 3, a water inlet pipe 4, a screw 5, an outlet pipe 6 and a positioning pin 7, and the tail mandrel 1 includes an outer cylinder 11 and an inner mandrel 12, and the inner mandrel 12 is installed in the outer cylinder 11, and also includes two sealing rings 2, the inner mandrel 12 is provided with two threaded holes 121, the right end of the inner mandrel 12 is provided with two concave round tables 122, the inner mandrel 12 A screw hole 123 is provided in the middle of the mandrel 12, and a sealing ring 2 is housed in each concave round platform 122, and the water inlet pipe 4 passes through the inner hole of the sealing ring 2 and is connected to the threaded hole at the upper position of the inner mandrel 12. 121 connection, the outlet pipe 6 passes through the inner hole of the sealing ring 2 and is connected with the threaded hole 121 at the lower position of the inner mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com