Gradient-method vacuumizing process and device for full-pressure-plug antibiotics bottle

A technology of antibiotics and vacuuming, which can be used in packaging under vacuum/special atmosphere, fixing stoppers, cleaning hollow objects, etc. It can solve the problems of plexiglass boxes that cannot be sterilized, slow speed, and labor-intensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

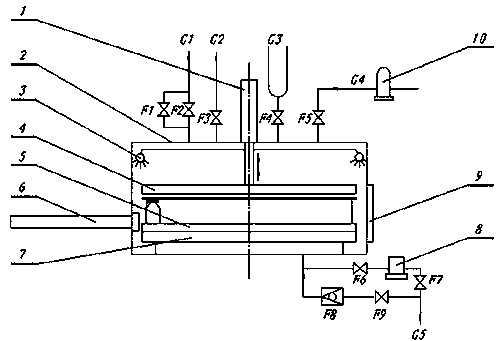

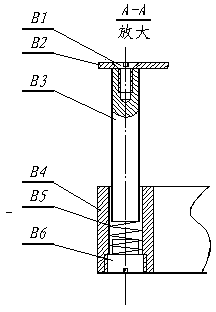

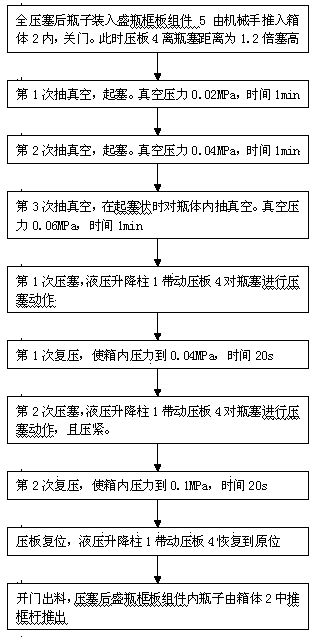

[0061] Such as figure 1 As shown in the schematic diagram of the structure and pipeline of the present invention, a device for vacuuming the gradient method of fully plugged antibiotic bottles is installed at the outlet of the delivery track of the powder injection dispensing machine, and the powder is dispensed into the powder and the fully plugged antibiotic bottles are placed in the Under the protection of A-level laminar flow, through the conveying track, it is sent into the gradient method vacuum pumping device, or, under the action of the mechanical device, it is arranged and inserted into the bottle holding frame plate assembly with buffer plate, and sent into the gradient method vacuum pumping device by the manipulator. In the vacuum device, the device for vacuuming by the gradient method includes a hydraulic lifting column 1, a casing 2, a pressing plate 4, a vacuum pipeline G1 and a pump body 8 arranged on the casing 2, wherein:

[0062] The upper surface of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com