Paying-off device

The technology of a pay-off device and a threaded barrel is applied in the field of the pay-off device, which can solve the problems such as the inability to apply the long-length spool, the labor intensity of the staff, the single function of the pay-off rack, etc. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

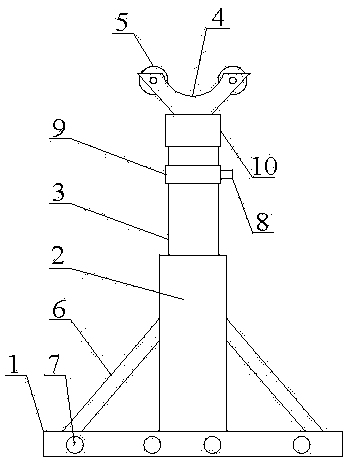

[0033] Such as figure 1 and figure 2 As shown, a pay-off device includes a base 1, an internally threaded cylinder 2, a screw rod 3, a Y-shaped bracket 4, a runner 5 and a fixed rod 6, the internally threaded cylinder 2 is arranged in the middle of the base 1, and the two fixed rods 6 The upper end is connected to the outer surface of the internally threaded cylinder 2, the lower ends of the two fixing rods 6 are connected to the two ends of the base 1 respectively, the screw rod 3 is arranged in the internally threaded cylinder 2 and threadedly connected with the internally threaded cylinder 2, and the Y-shaped bracket 4 is set On the top of the screw rod 3 , two runners 5 are symmetrically arranged on the top of the Y-shaped bracket 4 .

[0034] When the present embodiment is in use, two pay-off devices are used together. Place the two pay-off devices side by side, adjust the distance between the two pay-off devices, so that the rotating shafts at both ends of the reel ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com