Hopper feeder

A technology for feeding cotton and cotton boxes, which is applied in textiles and papermaking, fiber treatment, fiber feeding, etc. It can solve the problems of adverse effects in the downstream, many neps, bundles, poor mixing effect, etc., to improve production efficiency, Reduce the failure rate and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

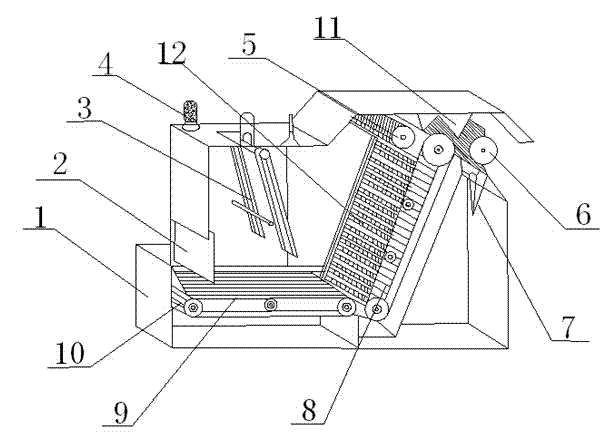

[0013] like figure 1 The cotton box feeding device shown in the figure includes a frame 1, a horizontal curtain 9, a brad-stud curtain 8 and a rocking plate 3. The bottom of the frame 1 is provided with a horizontal curtain 9, and the horizontal curtain 9 is connected with the brad-stud curtain 8. The upper end of the stud curtain 8 is provided with an equalizing roller 5, a stripping roller 6 is installed on one side of the equalizing roller 5, and the lower end of the stripping roller 6 is dust grid; the upper end of the frame 1 is installed with a rocking plate 2. The remote plate 2 is installed above the horizontal curtain 9, a baffle 2 is provided on one side of the horizontal curtain 9, the baffle 2 is connected to the frame 1, and the angle nails are provided on the angle nail curtain 8 12. The angle between the angle nails 12 and the angle nail curtain 8 is 45°. One side of the frame 1 is provided with a cotton feeding curtain 10, the cotton feeding curtain 10 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com