Pre-assembly integrated bathroom by modular ceramic tiles and assembly method of pre-assembly integrated bathroom

A technology for application modules and toilets, applied in the processing of building materials, small buildings, construction, etc., can solve the problems of long construction period from installation to use, failure to provide, etc., to achieve the effect of facilitating rapid installation and reducing construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

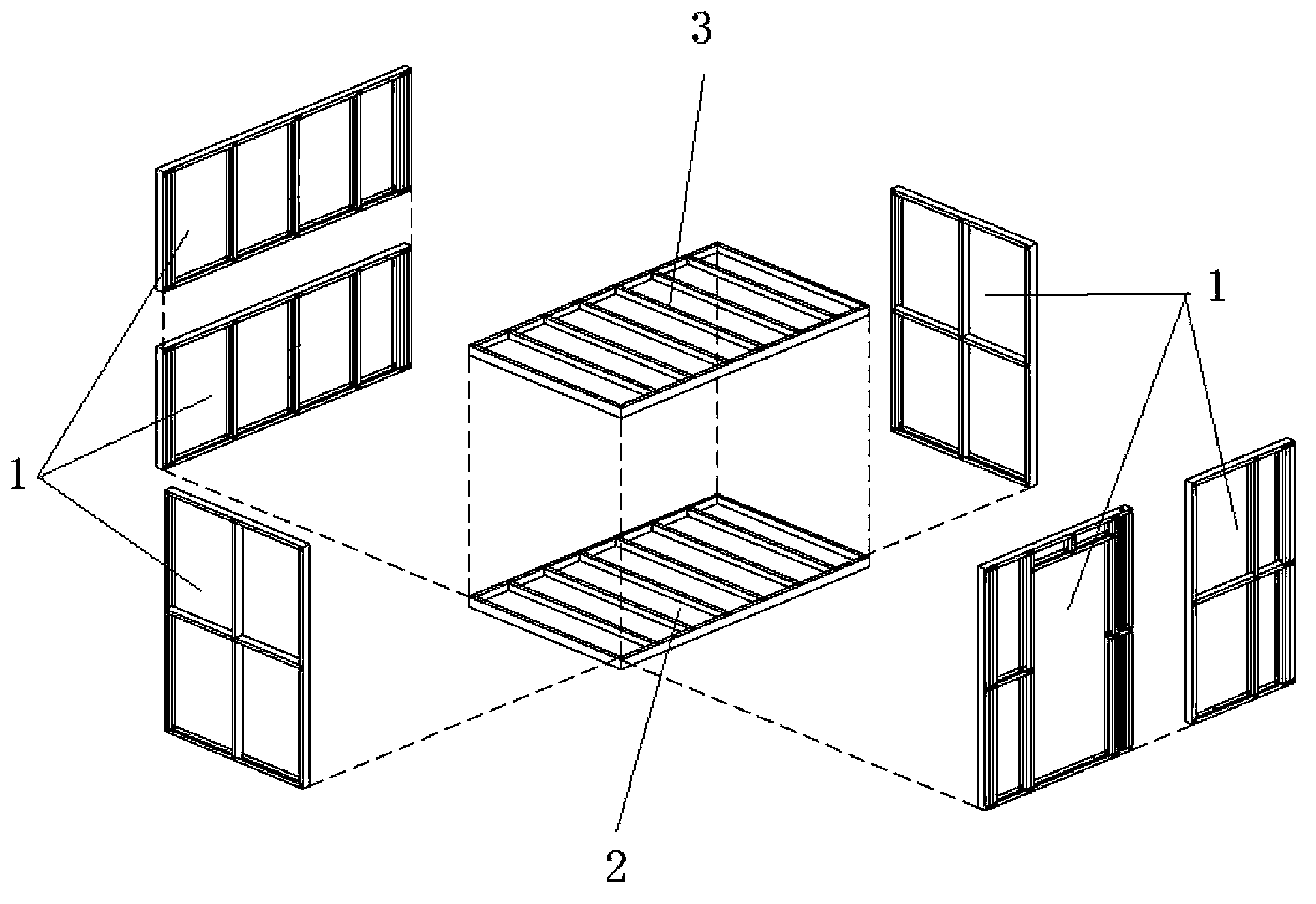

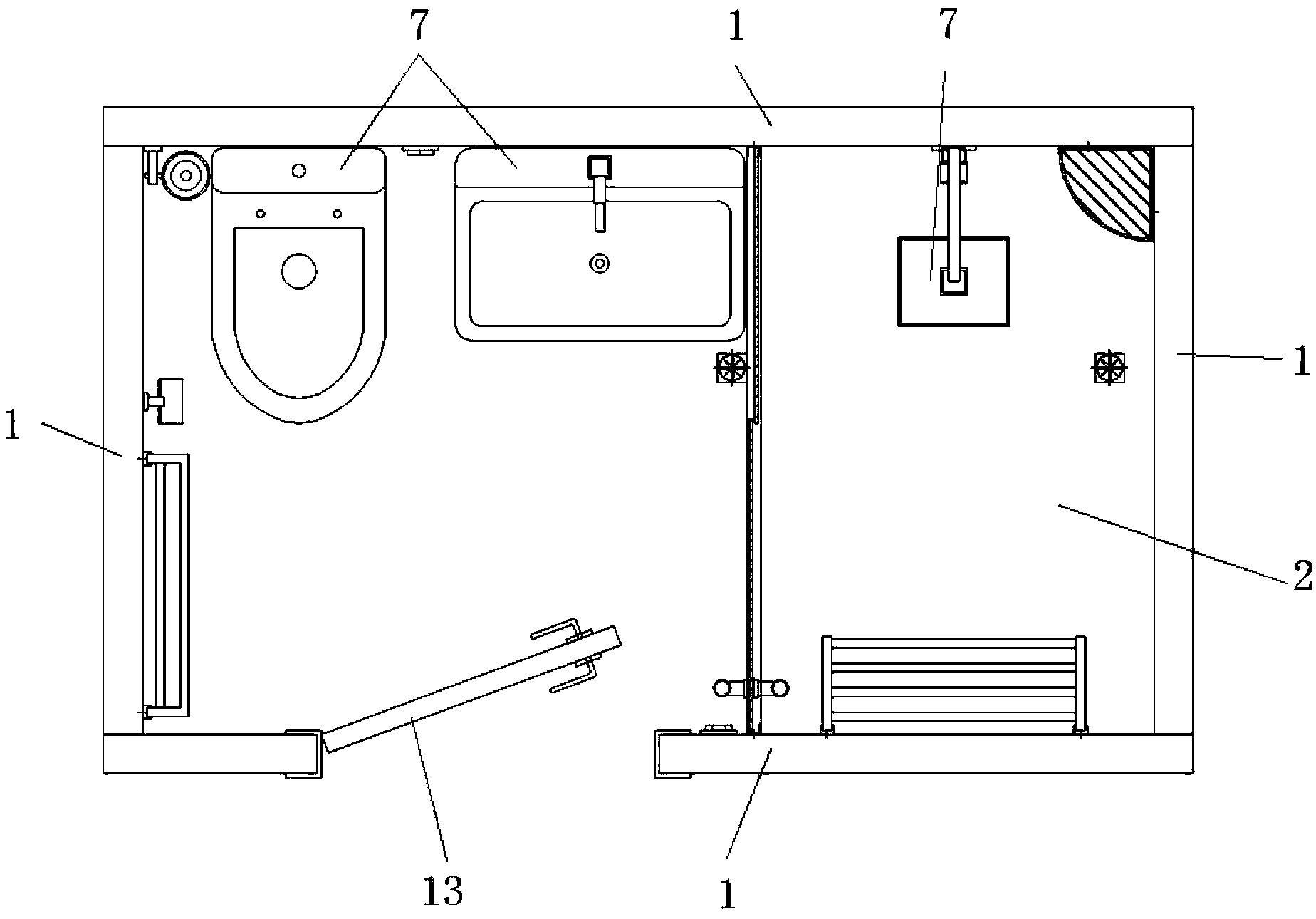

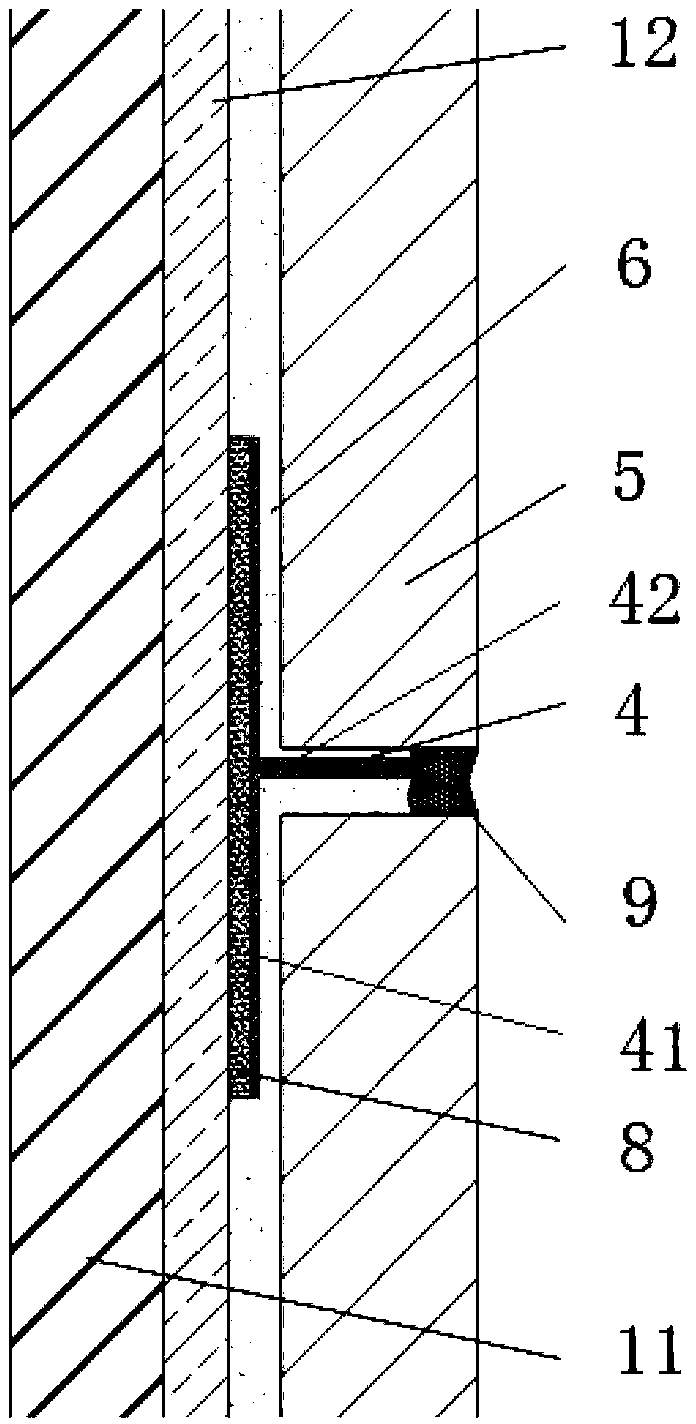

[0034] In the first embodiment of the present invention, please continue to refer to Figure 1 to Figure 4 shown. The interior of the above-mentioned outer wall 1 and bottom plate 2 is composed of a light steel keel 11 and a CFC board or a smooth board 12, and the light steel keel 11 is located on the outside of the toilet cabinet, and the CFC board or smooth board 12 is located on the outside of the toilet cabinet. inside.

[0035] In the second embodiment of the present invention, the above-mentioned tile fixing part 4 includes a connecting part 41 and a supporting part 42, and the connecting part 41 of the tile fixing part 4 fixes the CFC arranged on the outer wall 1 and the bottom plate 2 by coating the fixing layer 8 On the board or smooth board 12 , the supporting part 42 of the tile fixing part 4 is fixedly connected to the tile 5 through the filling layer 6 .

[0036] In the third embodiment of the present invention, the supporting part 42 of the tile fixing part 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com