Packed cofferdam filling mining method

A backfill mining and cofferdam technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of difficult mining, high mining cost, partitioned isolation and filling in difficult gob areas, and achieve safe and efficient mining and improve mining. rate and mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

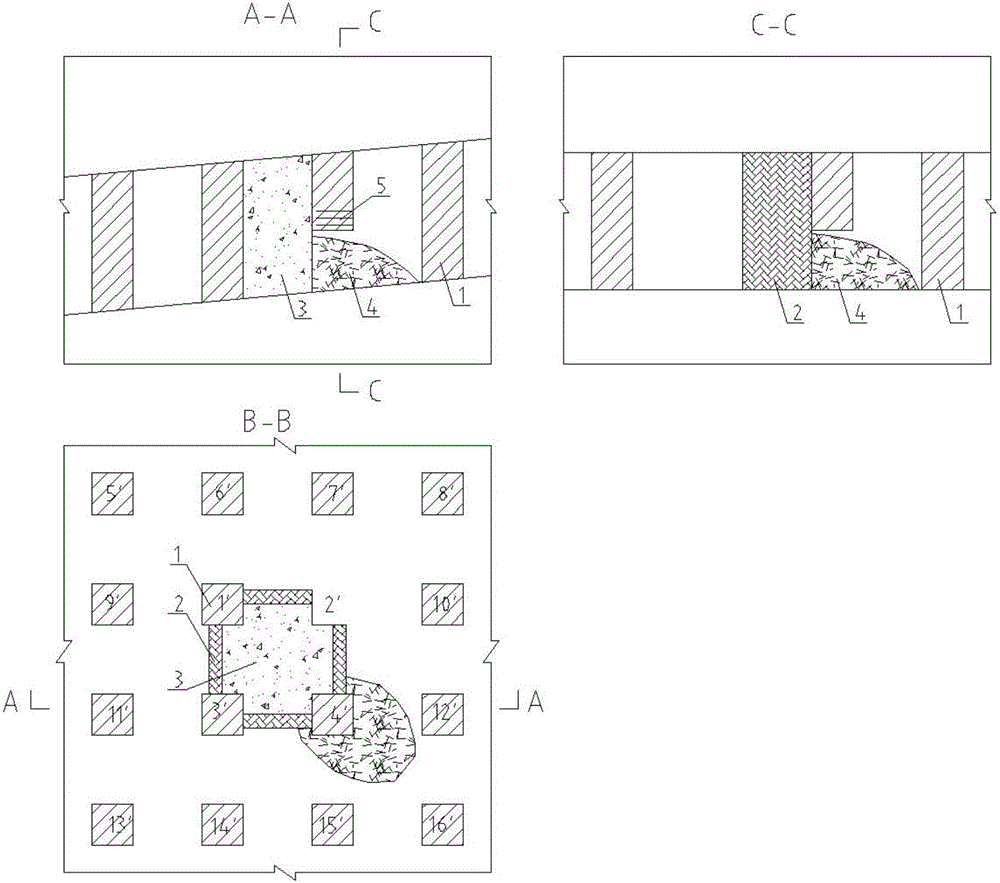

[0040] from figure 1 It can be seen that the bagged cofferdam filling mining method adopted in the present invention is suitable for partitioned isolation filling of goafs and partitioned mining of ore pillars.

[0041] Such as figure 1 As shown, when the ore rock is solid, the four ore pillars No. 1', 2', 3' and 4' and the through-space between them are divided into a mining zone.

[0042] The method of bagged tailings filling is used to form the cofferdam of the bagged filling body connected to the mining column. When constructing the bagged filling body cofferdam, at least one surface of the to-be-mined column must be located outside the cofferdam of the filling body and be connected to the pedestrian walk. , transportation, ventilation and other channels are connected. The specific steps of bag filling are as follows: ①Using steel pipe rods between the adjacent 1', 2', 3', 4' pillars to erect a three-dimensional mesh filling body fixed frame, the horizontal interval of t...

Embodiment 2

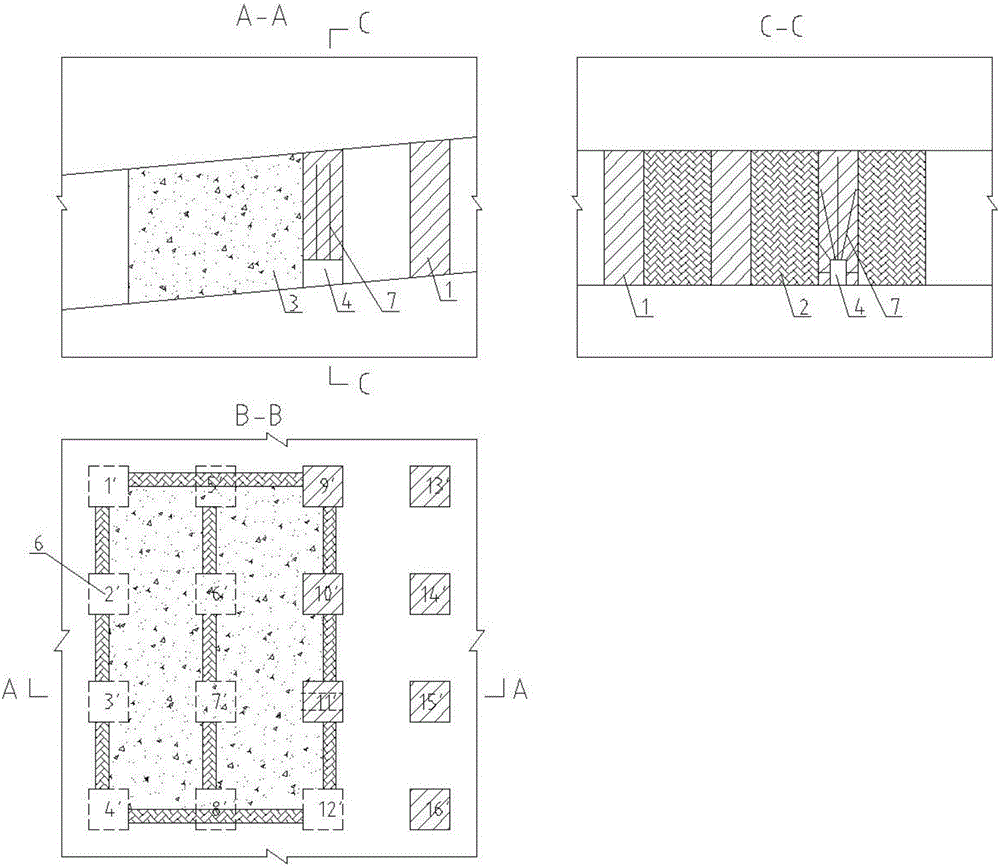

[0046] from figure 2 It can be seen that when the ore rock is very strong, the four ore pillars No. 9', 10', 11', and 12' and the through-space between them and the filling body in the mined area are divided into a mining area.

[0047] The method of bagged tailings filling is used to form the cofferdam of the bagged filling body connected to the column to be mined and the adjacent filling body. When constructing the cofferdam of the bagged filling body, at least one surface of the column to be mined must be located in the cofferdam of the filling body Outside, and connected with pedestrian, transportation, ventilation and other passages. The specific steps of bag filling are as follows: ① Use steel pipe rods to erect a three-dimensional mesh filling body fixing frame between No. 9', 10', 11', and 12' ore pillars and adjacent filling bodies, The horizontal interval is 2m, the vertical interval is 1m, and the steel pipes are connected by cast iron fasteners; The flexible wov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com