Spring Washers for Coil Springs

A technology of coil springs and spring pads, applied in the field of spring pads, can solve the problem that sacrificial anodes cannot be stably integrated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

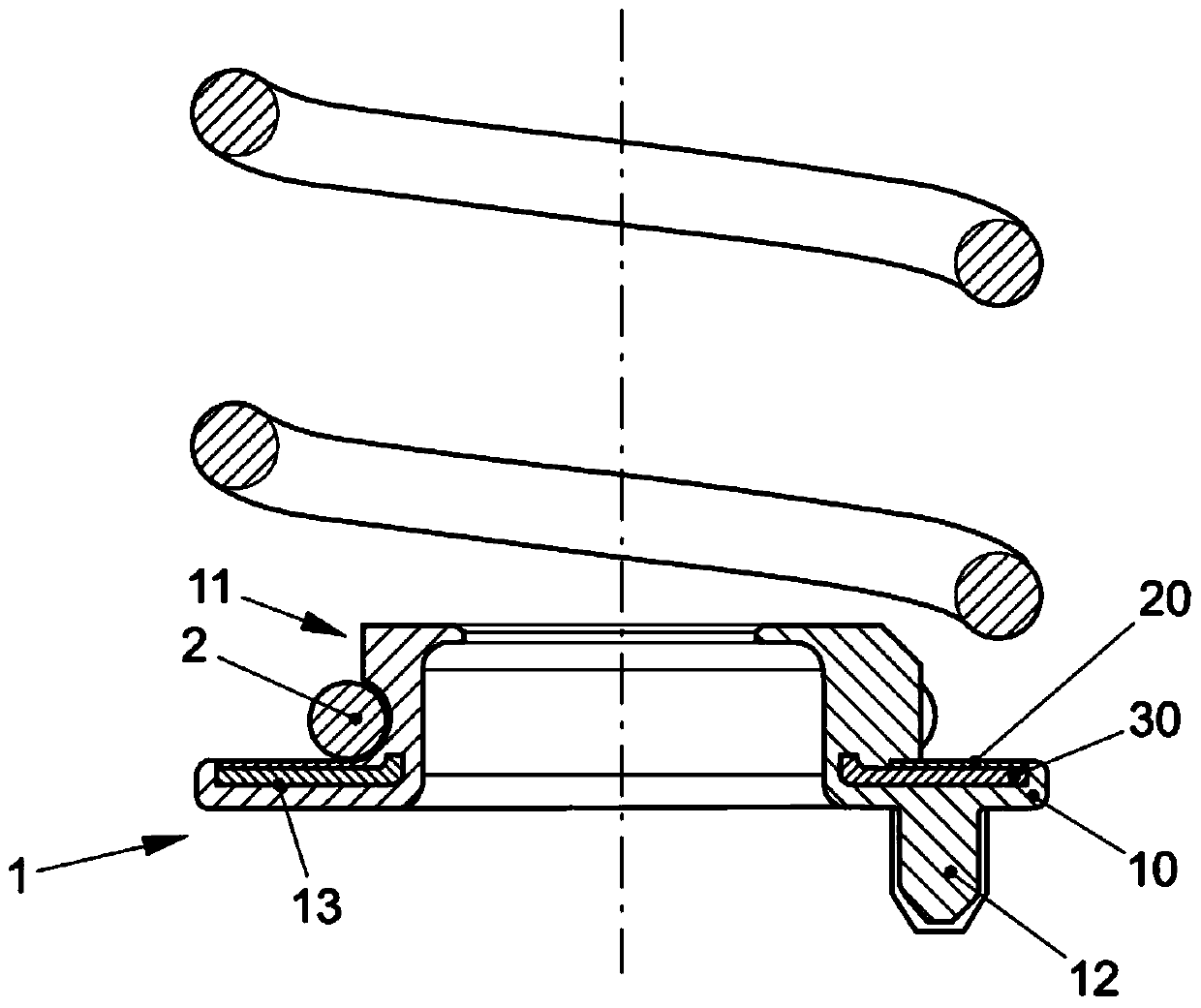

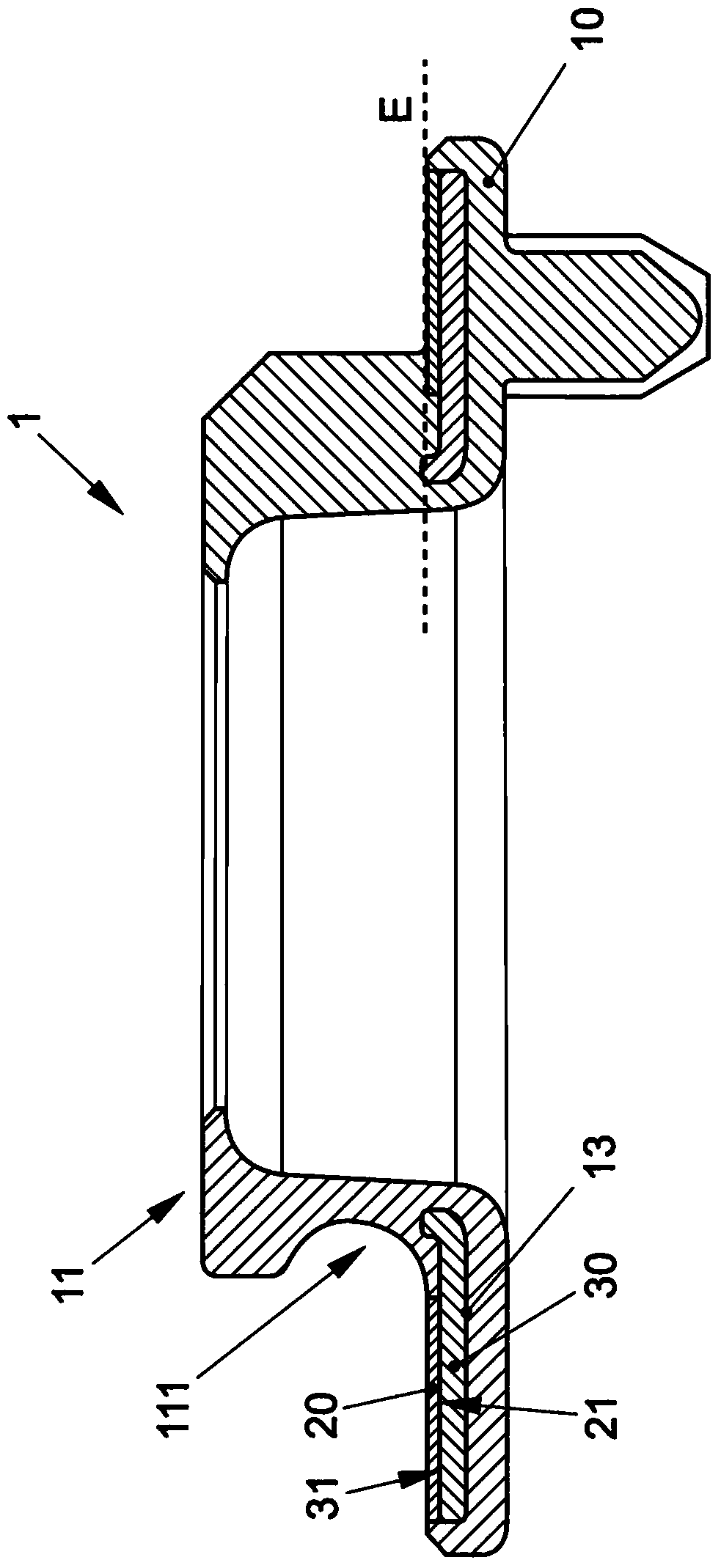

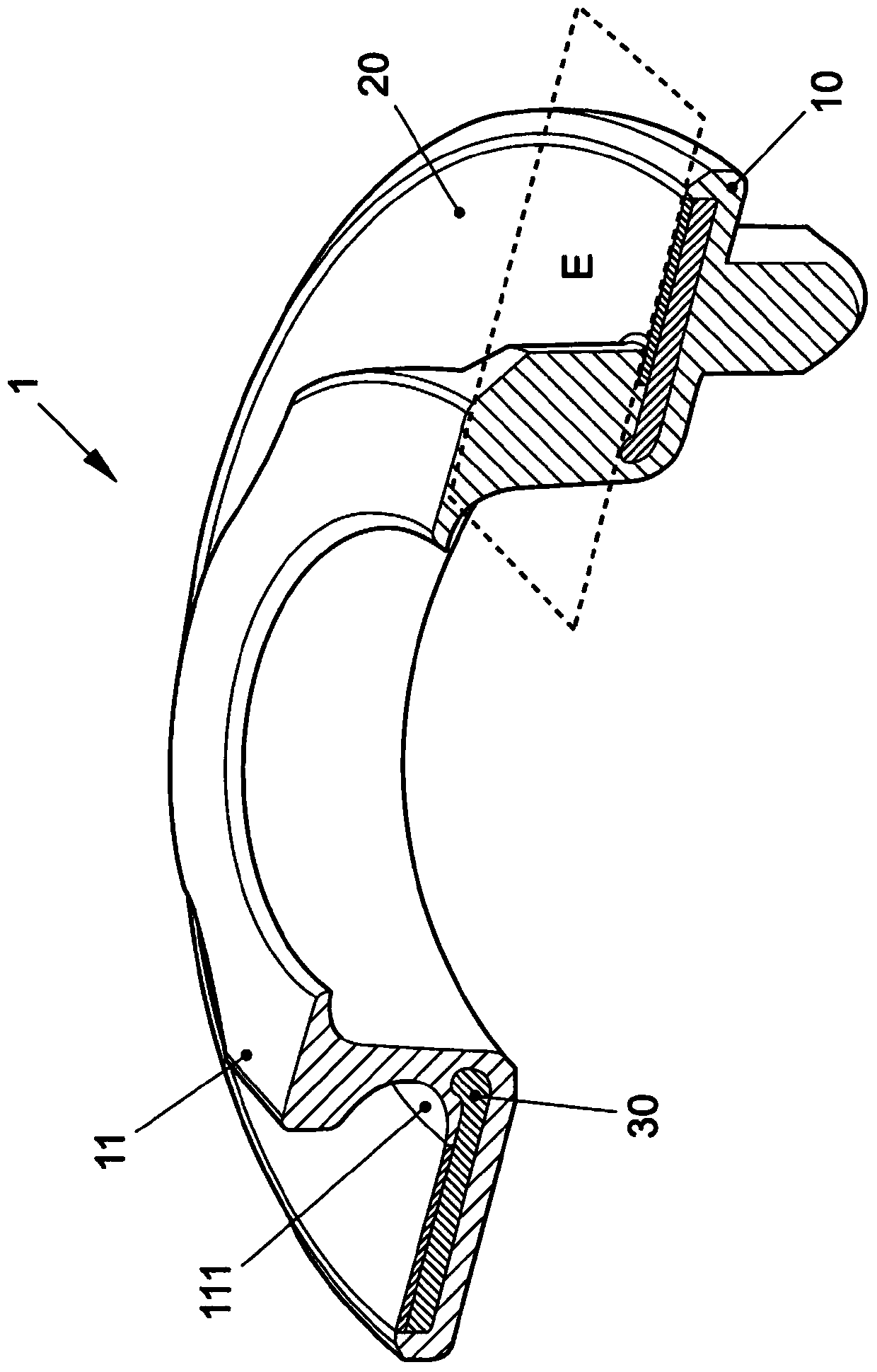

[0020] figure 1 The shown spring washer 1 is arranged in a motor vehicle and supports a helical spring 2 on one side, on the other side the spring washer 1 rests on a spring retainer (not shown) and thus rests on the helical spring (hereinafter also referred to as between the spring) 2 and the spring retainer.

[0021] The spring pad 1 comprises a base body 10 made of an elastomer. The basic body 10 serves to support the spring 2 and to dampen the sound of the spring relative to the vehicle body. For this purpose, the base body 10 is made of a soft, shock-absorbing material, such as rubber. The spring pad 1 also includes a sacrificial anode 20 . This sacrificial anode 20 is arranged on the spring side, so that said sacrificial anode is in direct contact with the spring 2 . Since the sacrificial anode 20 is made of a non-noble metal, such as zinc, it has a corrosion-proof effect on the spring 2 . An insert 30 made of a strong material is also embedded between the sacrifici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com