Totally chip-free spherical integrated hydraulic hose metal joint structure and production process thereof

A technology for metal joints and hydraulic hoses, applied in the direction of hose connection devices, pipes/pipe joints/fittings, engine components, etc., it can solve problems such as penetration or falling off of parts, and achieve the elimination of leakage risks and perfect production and use. , dimensional accuracy and the effect of improving material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings:

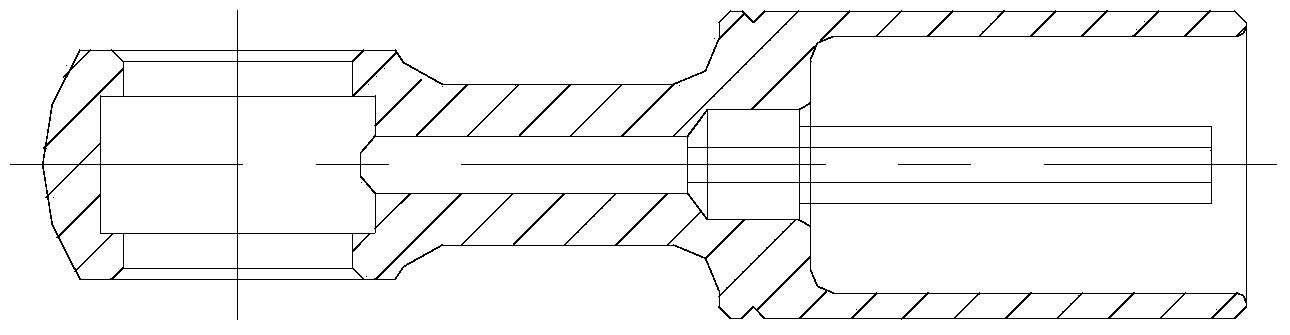

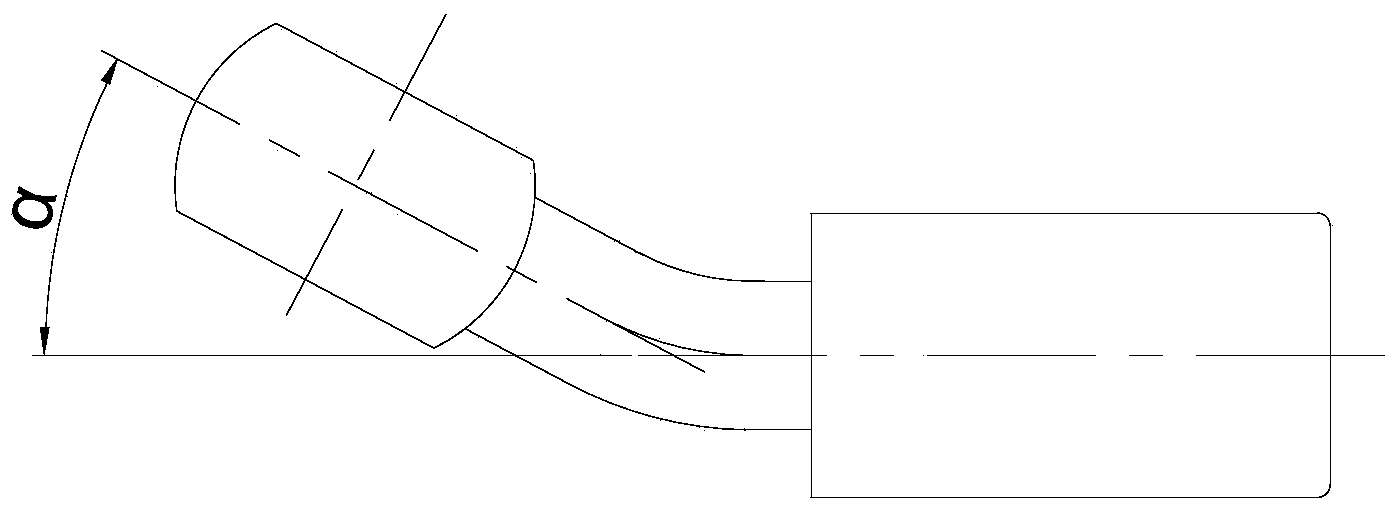

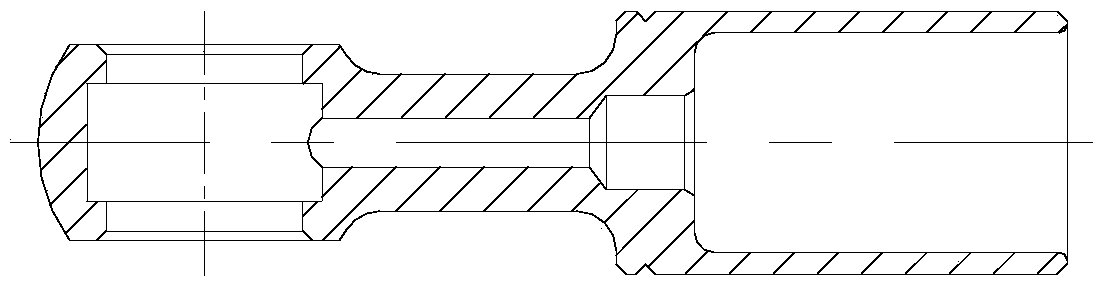

[0072] like Figure 5-Figure 7-12 , a completely chip-free spherical integral hydraulic hose metal joint structure, including a metal joint main body 1 and a sleeve 2, the metal joint main body 1 includes the ball joint 3, a three-way structure through hole 4, a hollow lined core tube 5. The lining core connecting pipe 6 and the connecting rod 8, one end of the connecting rod 8 is a ball joint 3, the other end of the connecting rod 8 is connected to the sleeve 2, and the inside of the connecting rod 8 is a hollow lining core pipe 5 and a lining core connecting pipe 6, wherein the lining The core connecting pipe 6 extends into the sleeve 2; the metal joint main body 1, the ball joint 3, the through hole 4 of the tee structure, the hollow lining core pipe 5, the lining core connecting pipe 6 and the connecting rod 8 are an integral structure.

[0073] The connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com