A phase transition radiator for a high power LED lighting lamp

A LED lighting and high-power technology, applied in the field of thermodynamics, can solve the problems that affect the light output efficiency and service life of lighting fixtures, cannot fully meet the heat dissipation requirements, and generate a large amount of heat, and achieve a reasonable circulation flow, light weight, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

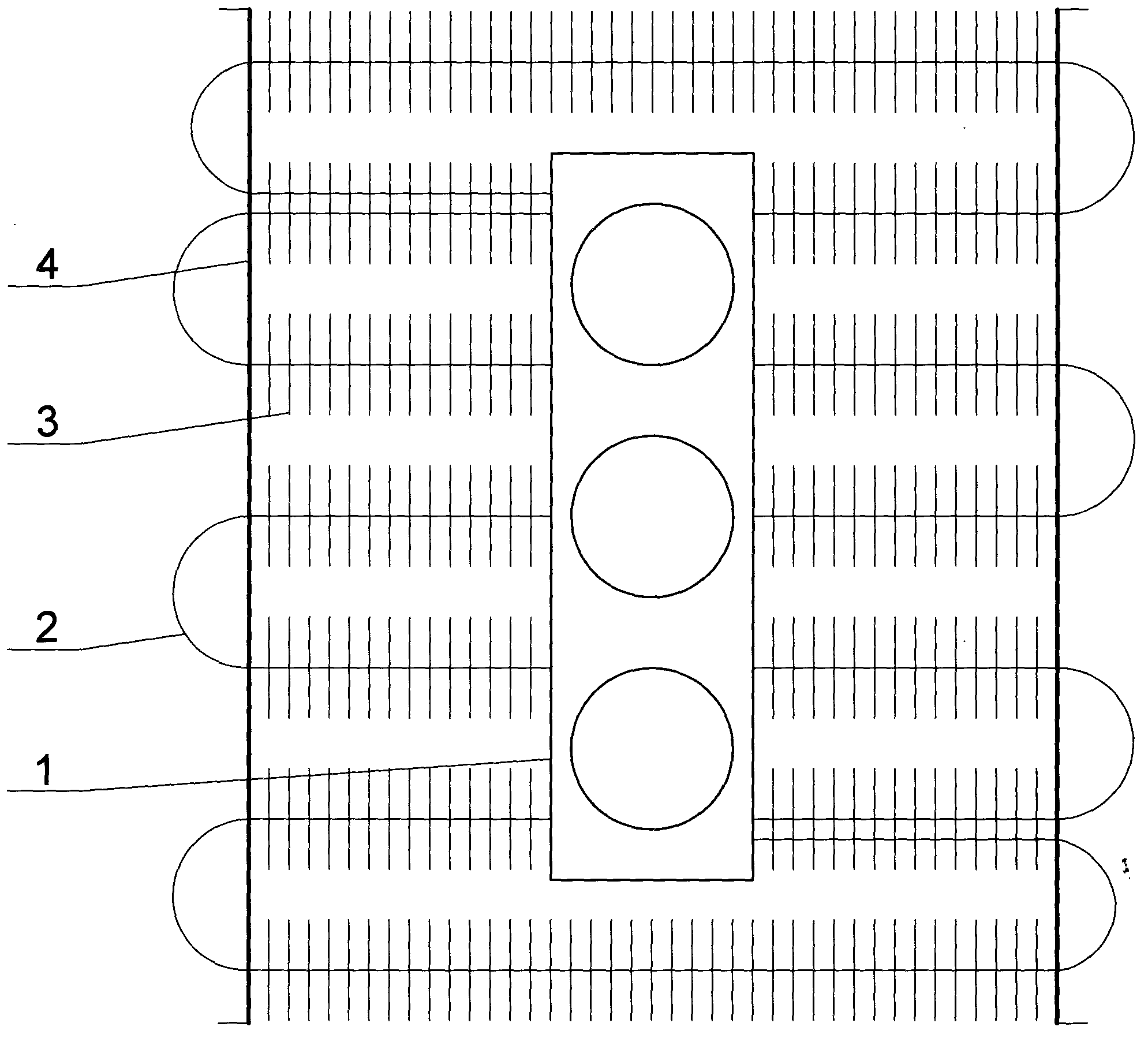

[0020] Such as figure 1 As shown, the evaporating coil (2) is made by bending a whole continuous pipe through multiple loops; the heat dissipation fins (3) are small fins arranged in a multi-piece distribution, and are tightly fixed on the evaporating coil ( 2) on. The steam outlet on the evaporator (1) is connected to the steam inlet pipe on the evaporator coil (2), and the steam inlet on the evaporator (1) is connected to the liquid return pipe on the evaporator coil (2). connected.

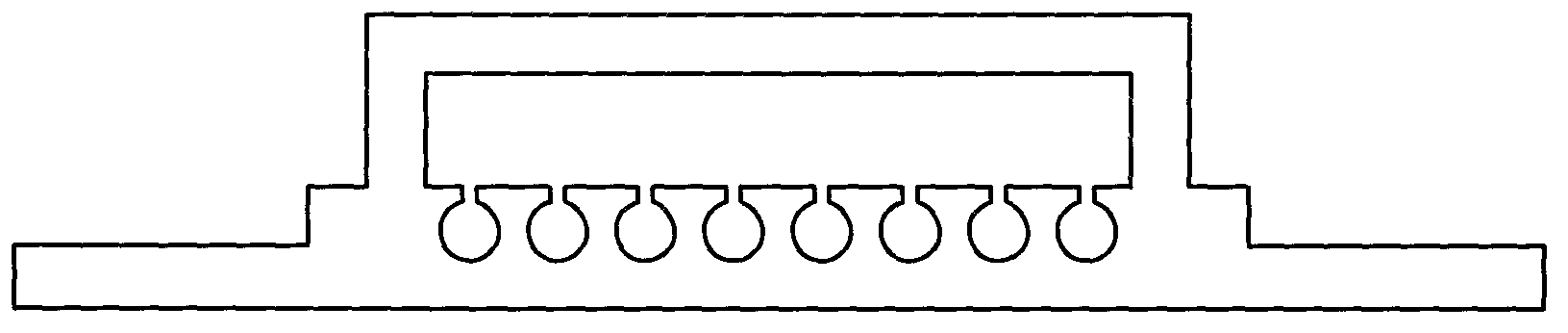

[0021] Such as figure 2 As shown, the evaporator (1) is composed of a cavity composed of a heat conduction plate and an evaporator shell, and the heat conduction plate in the cavity of the evaporator is provided with a grooved liquid-absorbing wick structure.

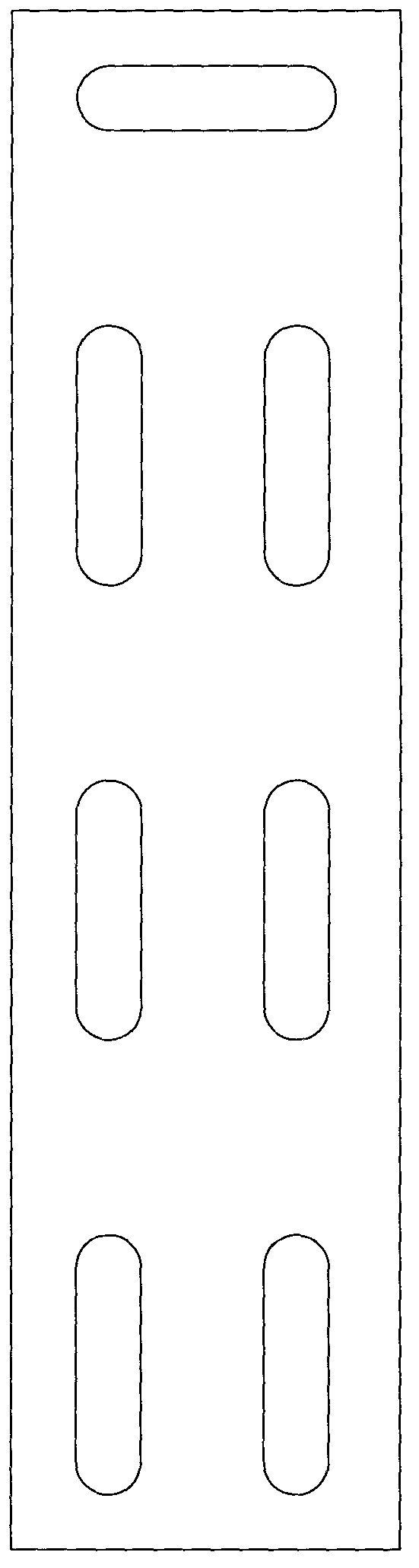

[0022] Such as image 3 or figure 1 As shown, the fixed baffle (4) is provided with longitudinal openings and transverse openings of the same size, which are installed on the curved end of the evaporation coil (2), parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com