Analyzing method for quickly and precisely measuring tellurium in tellurium smelting process

A smelting process and accurate measurement technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve problems such as instability and large error in results, and achieve high accuracy , the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

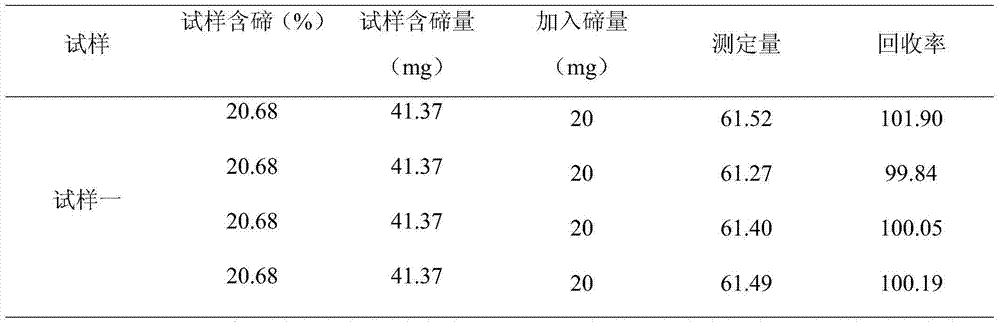

Embodiment 1

[0028] Weigh four parts of the standard management sample (the sample contains 20.36% tellurium), with a weight of 0.2000g, accurate to 0.0001g. Put the sample in a 400ml triangular beaker, slowly add 15ml of concentrated hydrochloric acid, 5ml of concentrated nitric acid, heat at low temperature to dissolve until nearly dry, add 5ml of concentrated hydrochloric acid, add 5ml of bromine water, continue heating and evaporate to dryness, repeat evaporation to dryness with concentrated hydrochloric acid twice , 5ml each time. Add 10ml of concentrated sulfuric acid, heat until thick white smoke comes out, add 100ml of ultrapure water and 10ml of concentrated hydrochloric acid after cooling, heat to boil to dissolve salts, and cool to room temperature. Accurately add 50ml of potassium dichromate standard solution, let it stand for at least 30min, add 20ml of sulfuric acid (1+1), 5ml of concentrated phosphoric acid, add 4 drops of sodium diphenylamine sulfonate indicator, titrate wi...

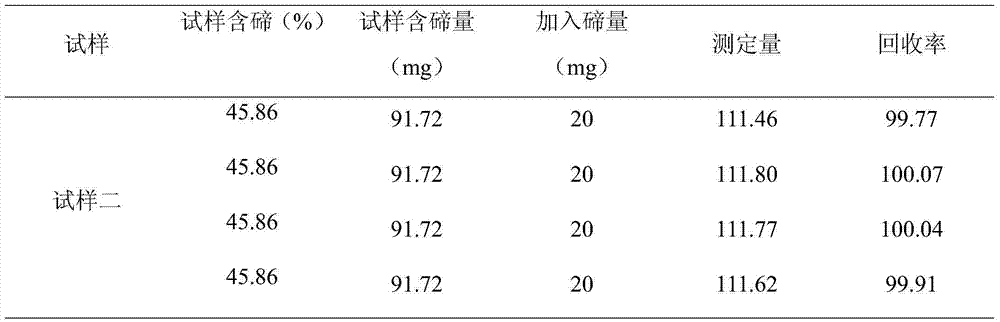

Embodiment 2

[0033] Weigh four parts of the standard management sample (the sample contains 45.86% tellurium), with a weight of 0.2000g, accurate to 0.0001g. Put the sample in a 400ml triangular beaker, slowly add 15ml of concentrated hydrochloric acid, 5ml of concentrated nitric acid, heat at low temperature to dissolve until nearly dry, add 5ml of concentrated hydrochloric acid, add 5ml of bromine water, continue heating and evaporate to dryness, repeat evaporation with hydrochloric acid twice, 5ml each time. Add 10ml of concentrated sulfuric acid, heat until thick white smoke comes out, add 100ml of ultrapure water and 10ml of concentrated hydrochloric acid after cooling, heat to boil to dissolve salts, and cool to room temperature. Accurately add 50ml of potassium dichromate standard solution, let it stand for at least 30min, add 20ml of sulfuric acid (1+1), 5ml of concentrated phosphoric acid, add 4 drops of sodium diphenylamine sulfonate indicator, titrate with ferrous ammonium sulfa...

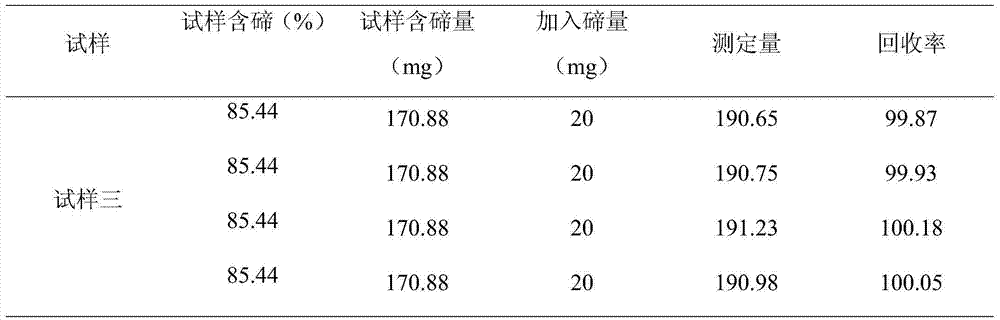

Embodiment 3

[0038] Weigh four parts of the standard management sample (the sample contains 85.44% tellurium), with a weight of 0.2000g, accurate to 0.0001g. Put the sample in a 400ml triangular beaker, slowly add 15ml of hydrochloric acid, 5ml of nitric acid, heat at low temperature to dissolve until nearly dry, add 5ml of concentrated hydrochloric acid, add 5ml of bromine water, continue heating and evaporate to dryness, repeat evaporation with hydrochloric acid twice, each time 5ml. Add 10ml of concentrated sulfuric acid, heat until thick white smoke comes out, add 100ml of ultrapure water and 10ml of concentrated hydrochloric acid after cooling, heat to boil to dissolve salts, and cool to room temperature. Accurately add 50ml of potassium dichromate standard solution, let it stand for at least 30min, add 20ml of sulfuric acid (1+1), 5ml of concentrated phosphoric acid, add 4 drops of sodium diphenylamine sulfonate indicator, titrate with ferrous ammonium sulfate standard solution until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com