Fast and Rigorous Simulation Method for Diffraction Spectra of Defective Masks in Extreme Ultraviolet Lithography

A technology of extreme ultraviolet light and simulation method, which is applied to microlithography exposure equipment, photolithography process exposure devices, instruments, etc., can solve the problems of large amount of calculation, slow calculation speed, unfavorable mask simulation calculation and data statistical analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with embodiments and drawings, but this embodiment should not limit the protection scope of the present invention.

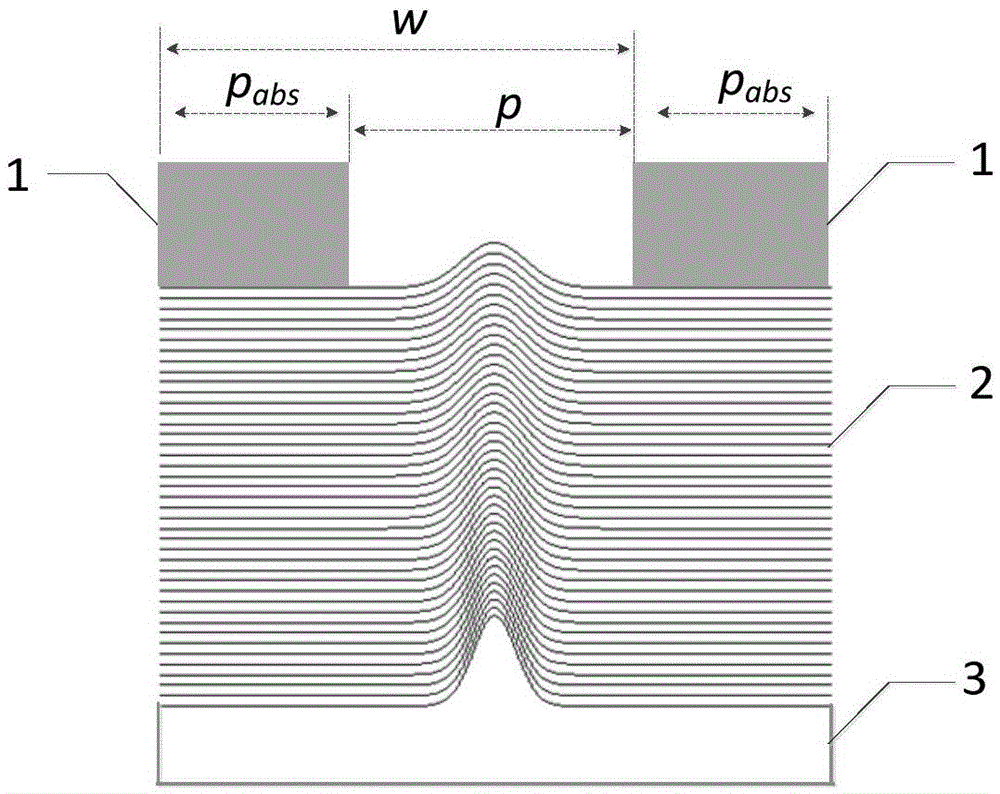

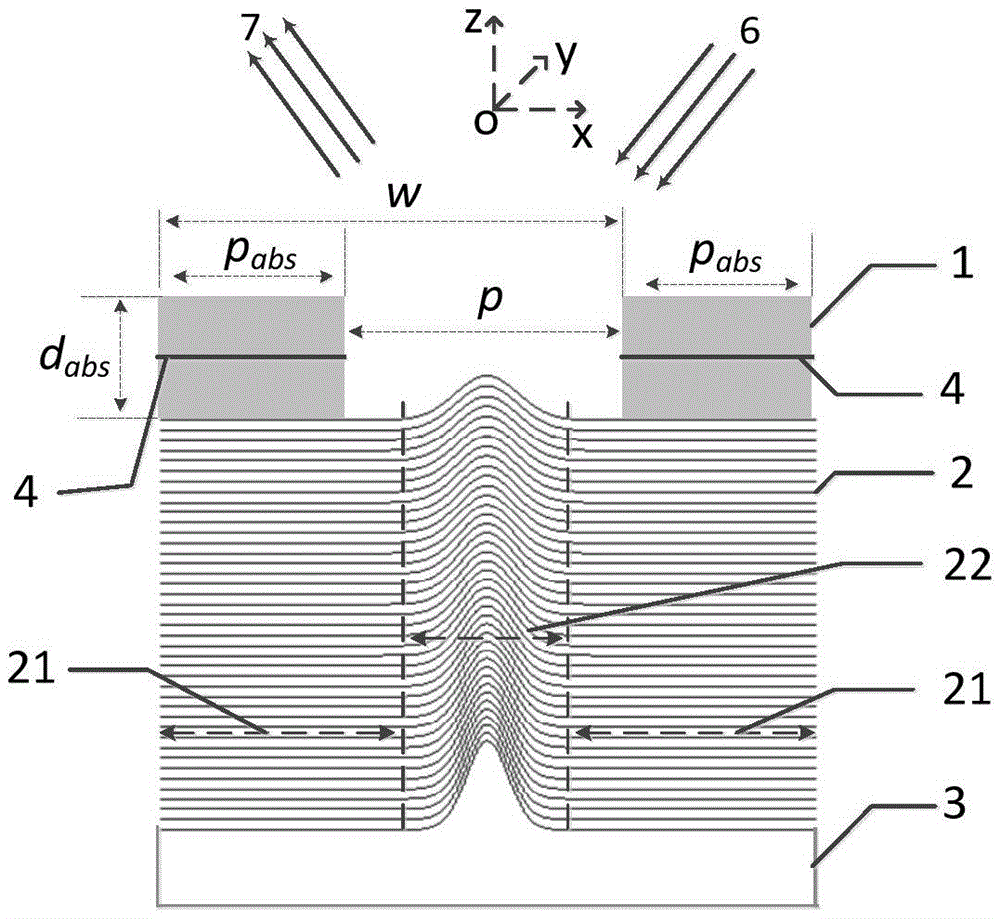

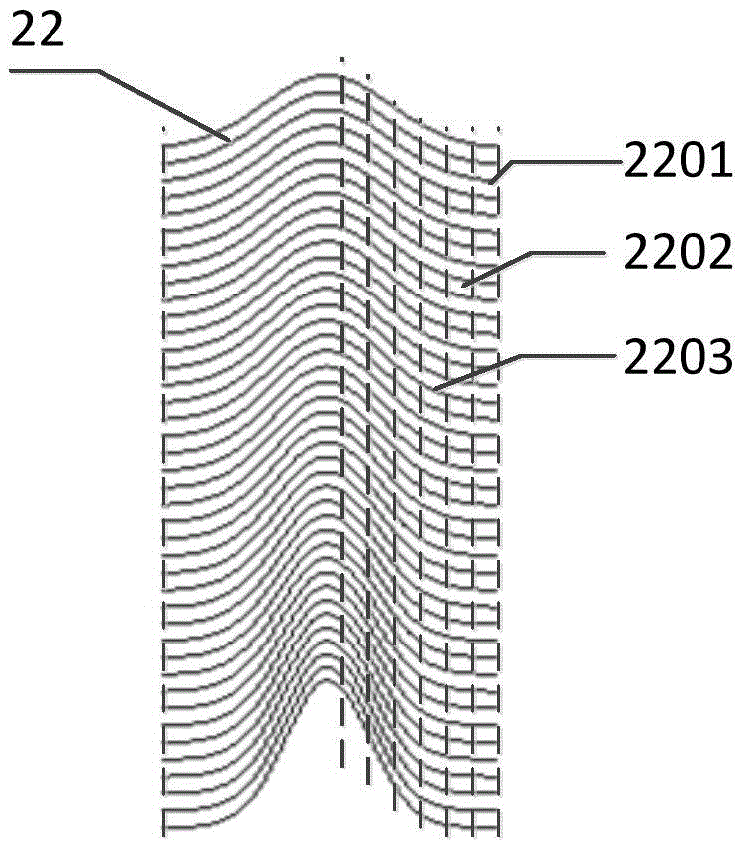

[0056] See first figure 1 with figure 2 , figure 1 It is a schematic diagram of the basic structure of a defect-containing mask for extreme ultraviolet lithography used in the present invention, which mainly includes a mask absorbing layer 1, a defect-containing multilayer film 2 and a substrate 3. figure 2 It is the basic principle and structural schematic diagram of the fast and strict simulation model of the present invention, in which the defects in the defect-containing multilayer film 2 are Gaussian defects, and the substrate defect height is 40nm, the full width at half maximum is 40nm, and the surface defect height is 5nm, half-peak The full width is 90 nm, the mask absorption layer 1 is modeled by the equivalent thin mask model 4, and the defect-containing multilayer film 2 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com