Durable anti-inclination acid-proofing explosive-proof electrolyte-rich starting lead-acid storage battery

A technology for lead-acid batteries and batteries, applied in the direction of lead-acid batteries, lead-acid battery construction, batteries, etc., can solve problems such as safety, battery acid mist escape, hidden dangers, etc., to improve battery capacity and life, and eliminate safety hazards , the effect of preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the specification.

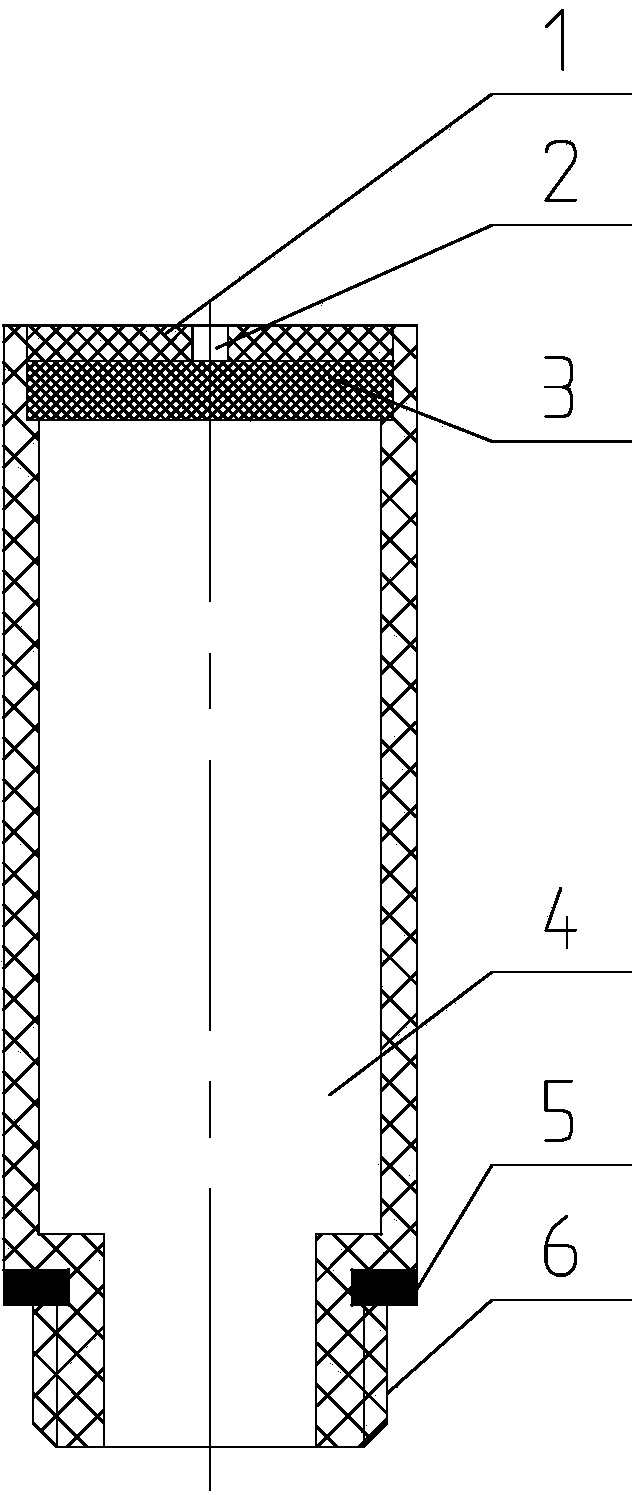

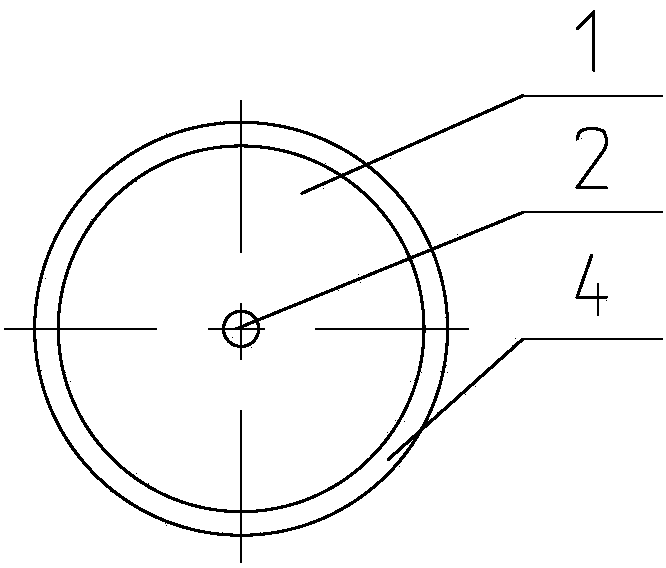

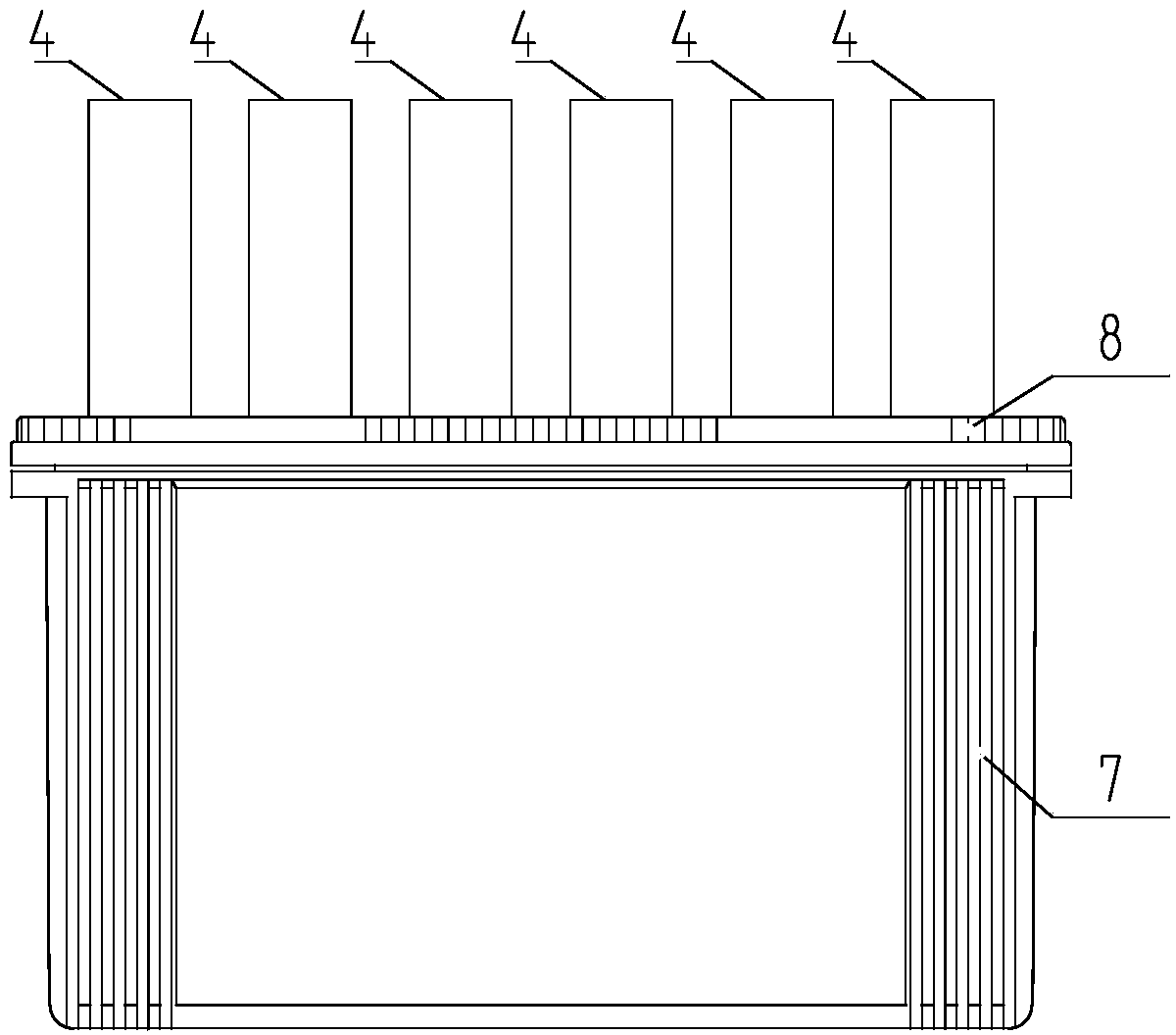

[0018] Such as figure 1 , 2 3. As shown in 3, the present invention includes a battery, a box 7 sheathed on the battery, and an upper cover 8 matching the box 7. The upper cover 8 is provided with a plurality of liquid injection ports, and is characterized in that: The liquid injection port is provided with an anti-overflow component, and the anti-overflow component includes an anti-overflow pipe 4, an explosion-proof acid filter plate 3 arranged on the upper part of the anti-overflow pipe 4, and a small ventilation cover located above the explosion-proof acid filter plate 3. 1. The gasket 5 is located at the lower part of the anti-overflow pipe 4, the vent hole 2 is provided in the middle of the small ventilating cover 1, the inner cavity of the anti-overflow pipe 4 constitutes a liquid chamber, and the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com