Permanent magnet synchronous motor

A permanent magnet synchronous motor and permanent magnet technology, which can be used in motors, electromechanical devices, electric vehicles, etc., can solve the problems of high vehicle cost and large built-in space occupied by the power system, and achieve the effect of reducing occupied space and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

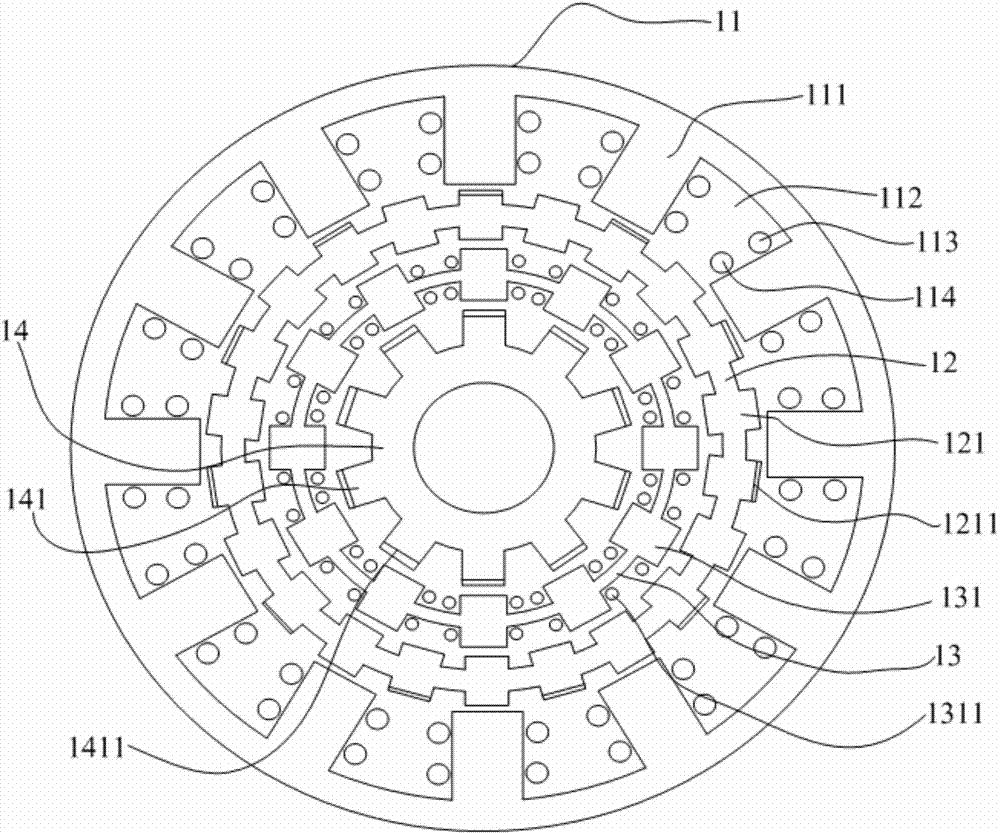

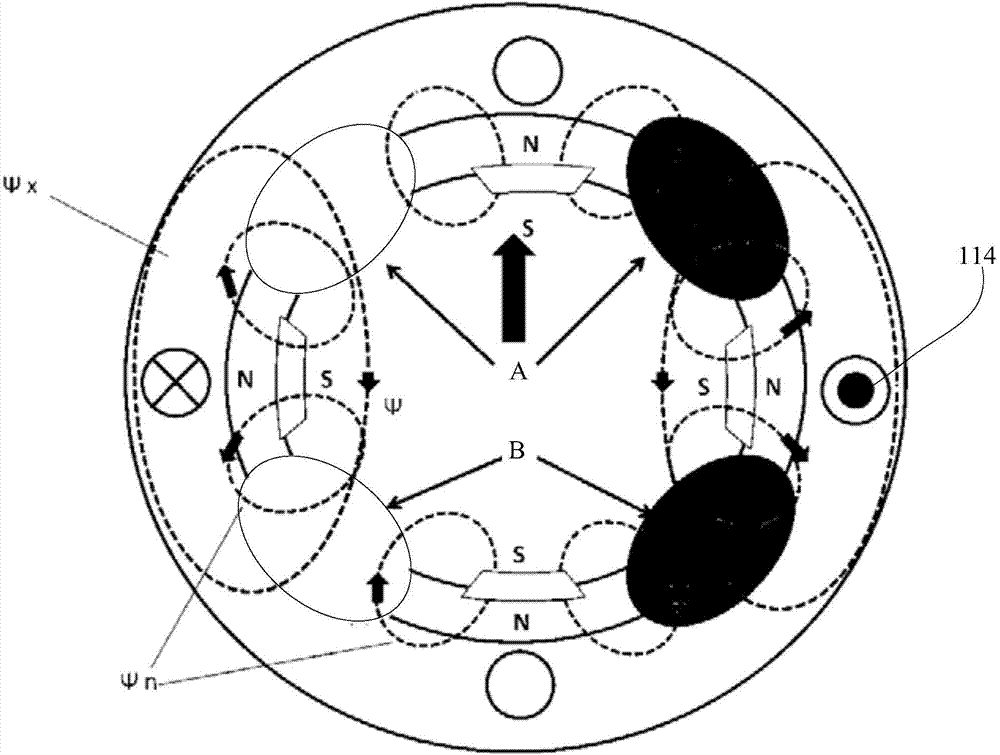

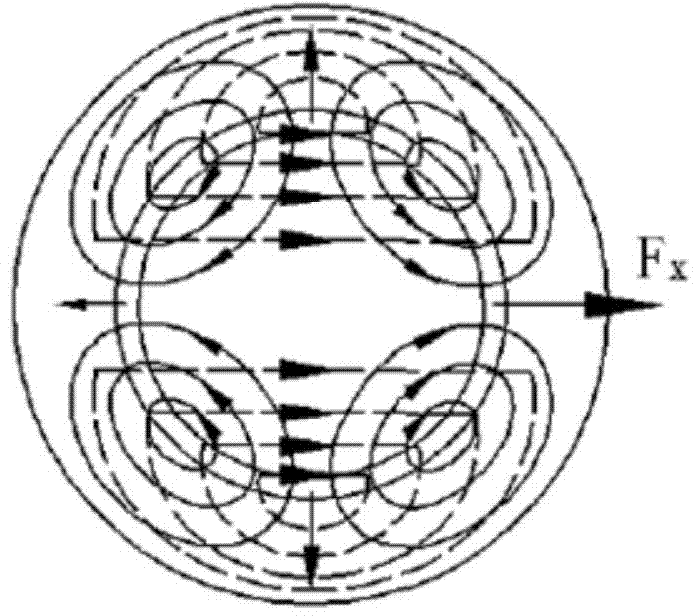

[0035] See figure 1 , The embodiment of the present invention provides a permanent magnet synchronous motor, which includes an annular stator core 11, an intermediate rotor 12, an adjusting rotor 13, an inner rotor 14 and a magnetic suspension bearing (not shown in the figure). The magnetic suspension bearing is used to position the intermediate rotor 12 and adjust the axial direction of the rotor 13. The stator core 11 has a plurality of first teeth 111 and a plurality of first teeth 111 separated by a plurality of first teeth 111 on the circumference of the stator core 11 in the radial inward direction. In the first slot 112, the drive winding 113 and the control winding 114 are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com