Novel door/window profile and mounting method thereof

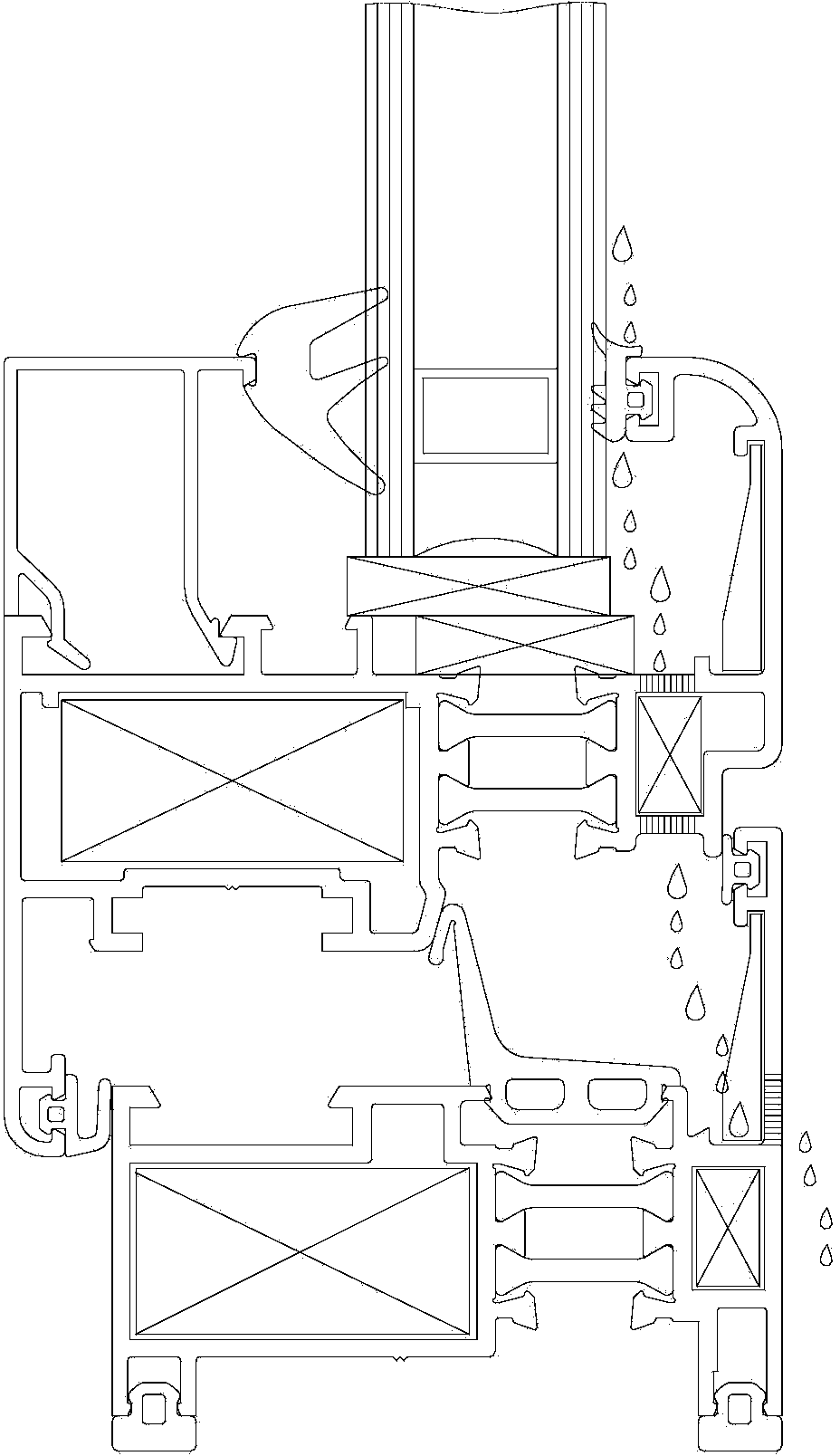

A door and window profile and profile technology, which is applied in the direction of sealing device, window/door frame, base frame, etc., can solve the problems of affecting the aesthetics of doors and windows, easy to produce rainwater intrusion, damp decoration system, etc., to achieve better drainage effect and high popularity High performance, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

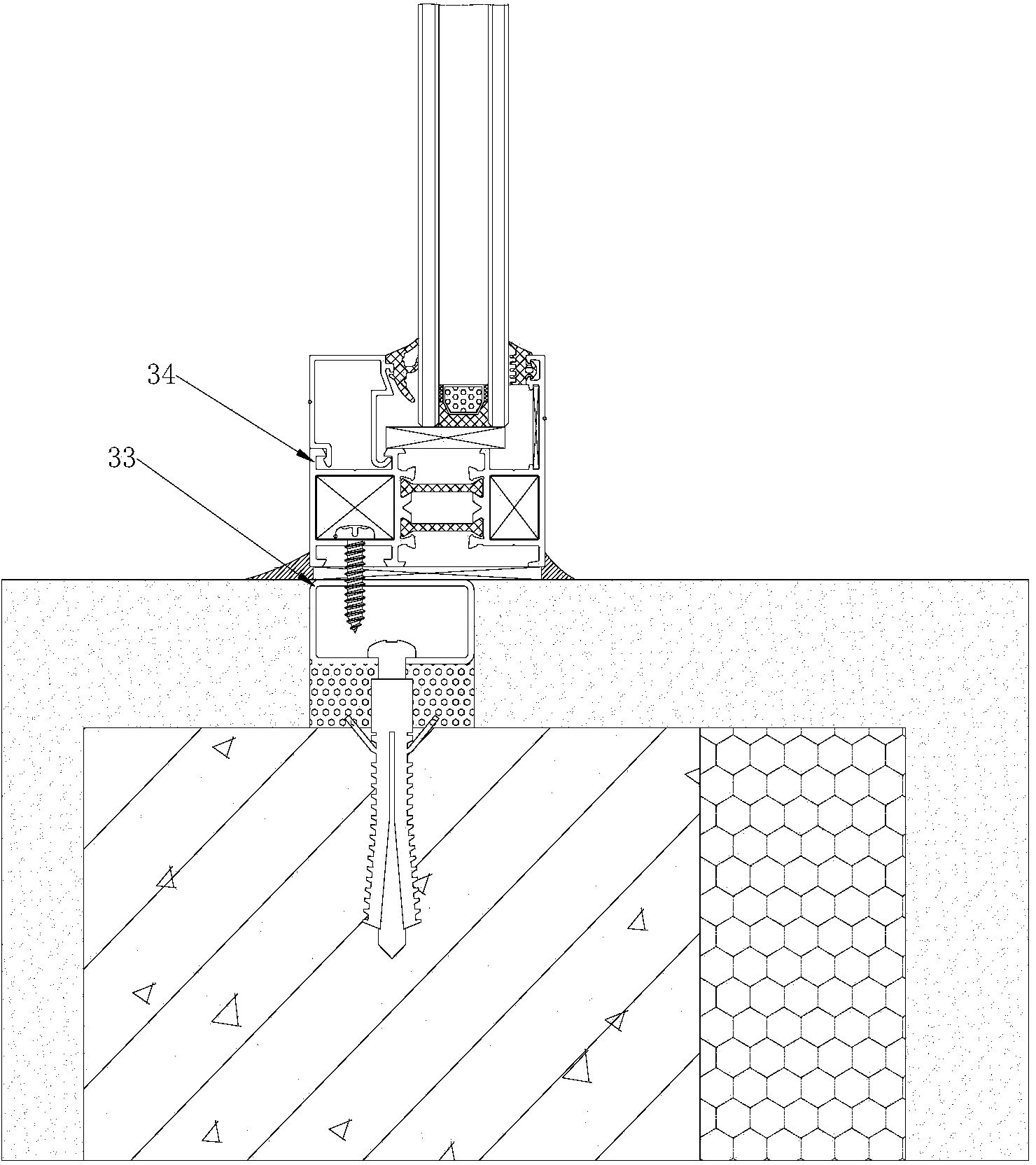

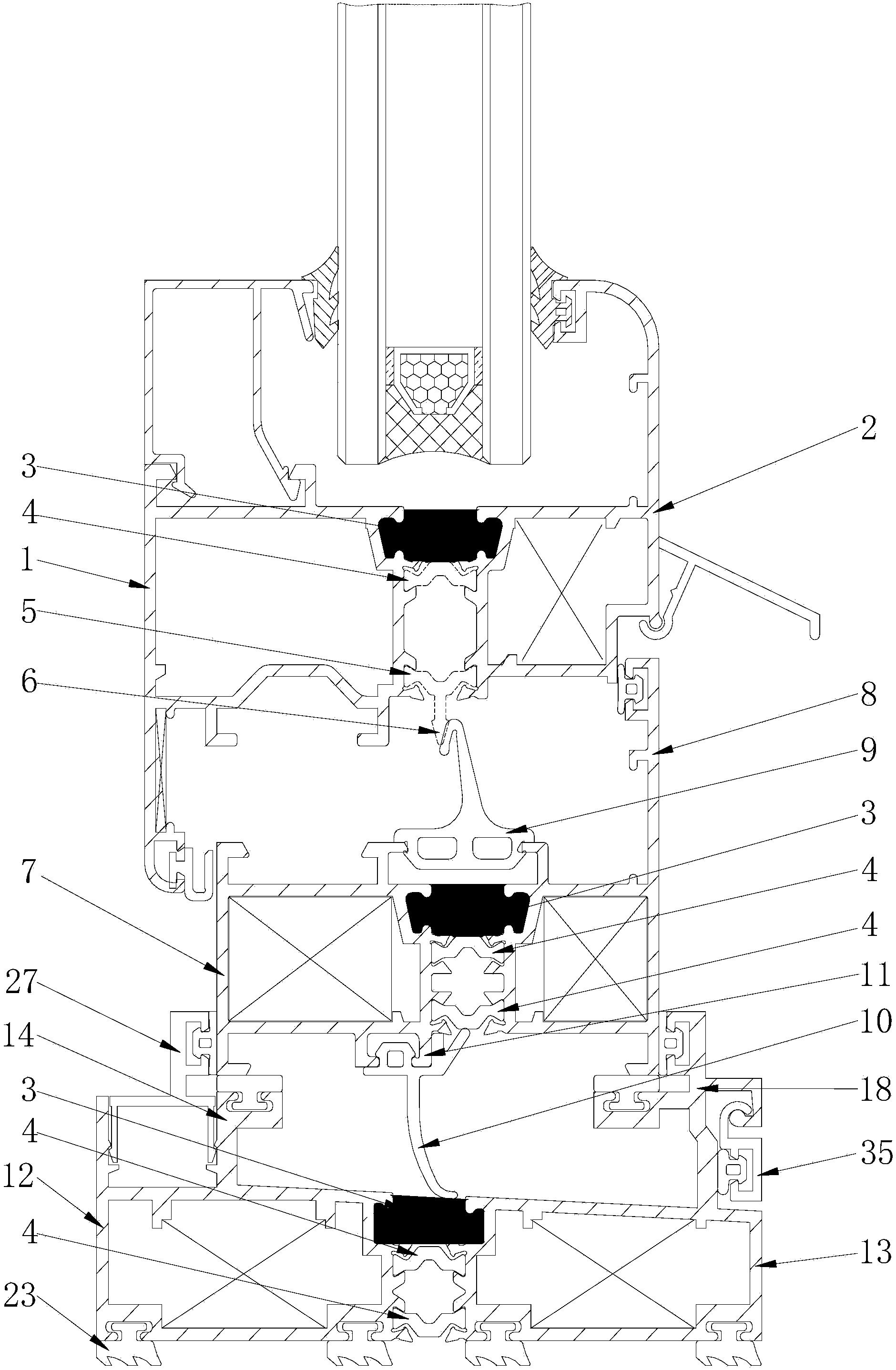

[0046] Such as image 3 As shown, taking the heat-insulating profile as an example, the door and window profile of Embodiment 1 includes:

[0047] 1) Door and window profiles: composed of door and window interior parts 1, door and window exterior parts 2 and door and window heat insulation strips. The door and window heat insulation strips include a pouring heat insulation strip 3 , a first piercing heat insulation strip 4 and a second piercing heat insulation strip 5 . The second piercing heat insulation strip 5 is provided with an overlapping edge 6 arranged along the longitudinal direction of the second piercing heat insulation strip 5 . The cross-section of the overlapping edge 6 in this embodiment is arrow-shaped.

[0048] 2) Door and window frame profiles: composed of door and window frame interior parts 7, door and window frame exterior parts 8 and door and window frame heat insulation strips. The door and window frame heat insulation strip includes a pouring type he...

Embodiment 2

[0066] Such as Figure 14 As shown, the difference between Embodiment 2 and Embodiment 1 lies in that the installation groove 11 for placing the second duckbill strip 10 is locked on the door and window frame inner part 7 by screws.

Embodiment 3

[0068] The door and window profiles of the present invention can also be applied to common aluminum profiles.

[0069] Such as Figure 15 As shown, the door and window sash profiles, door and window frame profiles and attached frame profiles are all integrated structures.

[0070] Similar to the structure of the door and window profiles in Embodiment 1, in Embodiment 3, an indoor positioning member 14 is provided on the indoor side 39 of the framed profile. The indoor positioning member 14 is provided with a first groove 15 , and a rubber pad 16 for sealing is installed in the first groove 15 . At this time, the rubber pad 16 on the indoor positioning member 14 provides a side blocking surface 17 of the indoor member for defining the placement position of the door and window frame profile.

[0071] An outdoor positioning part 18 is arranged on the outdoor side 40 of the framed profile. The outdoor positioning member 18 is provided with a first groove 15 and a second groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com