Carrying device and carrying platform flatness adjusting method

A technology of a bearing device and an adjustment method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven and stable blowing effect of the air outlet unit, large adjustment error, correction error, etc., to improve the sagging deformation phenomenon, accurate The effect of flatness correction and avoiding false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

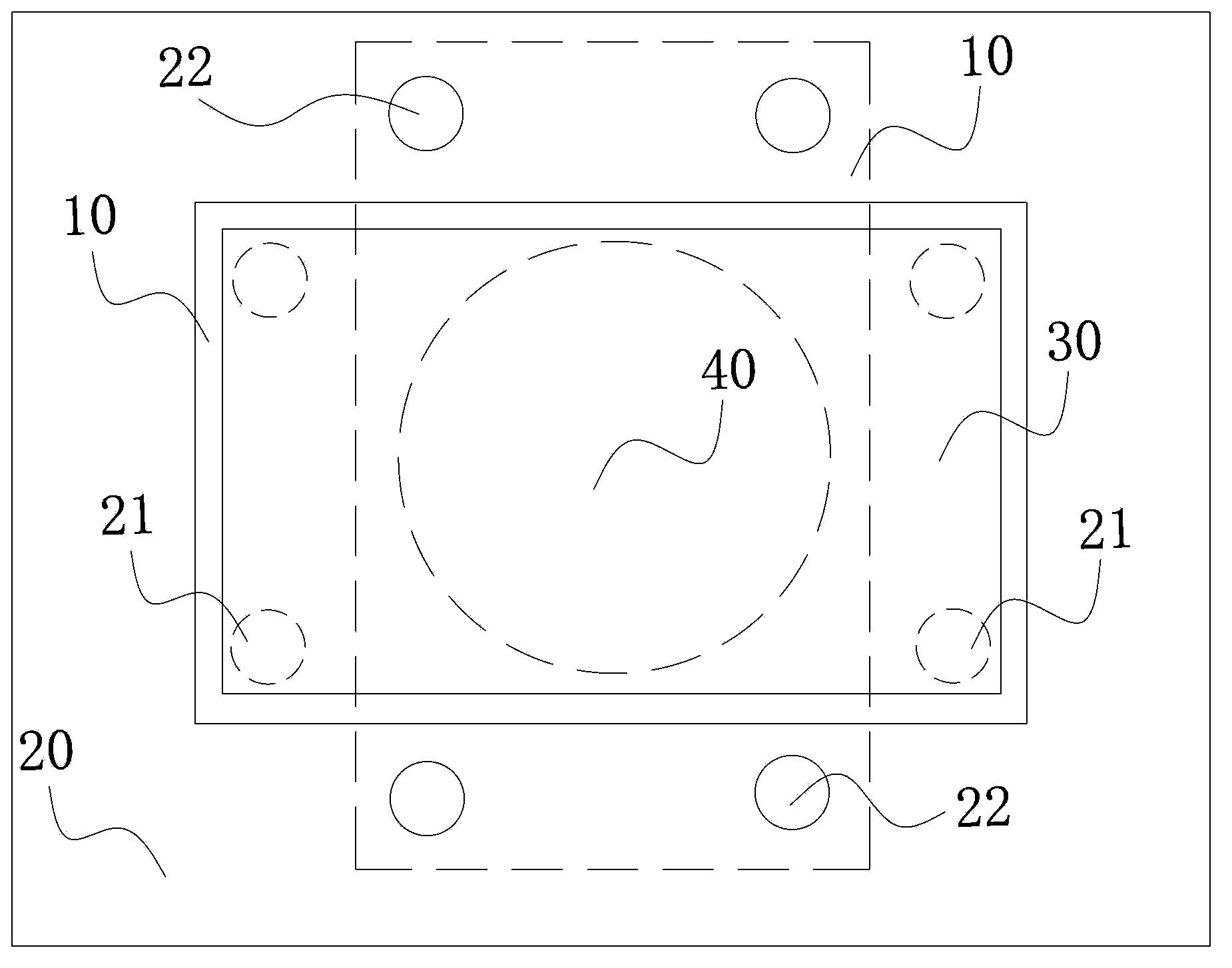

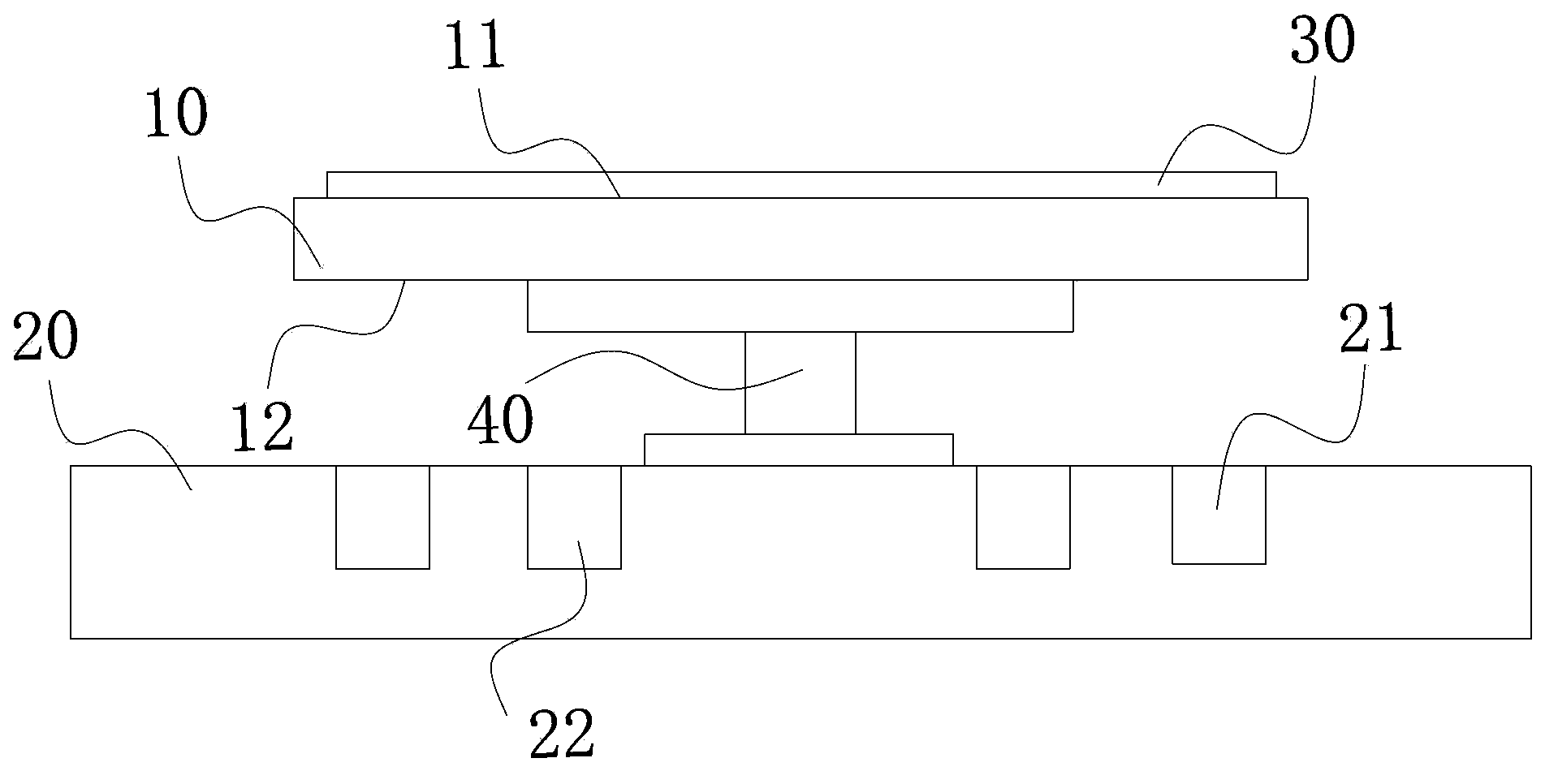

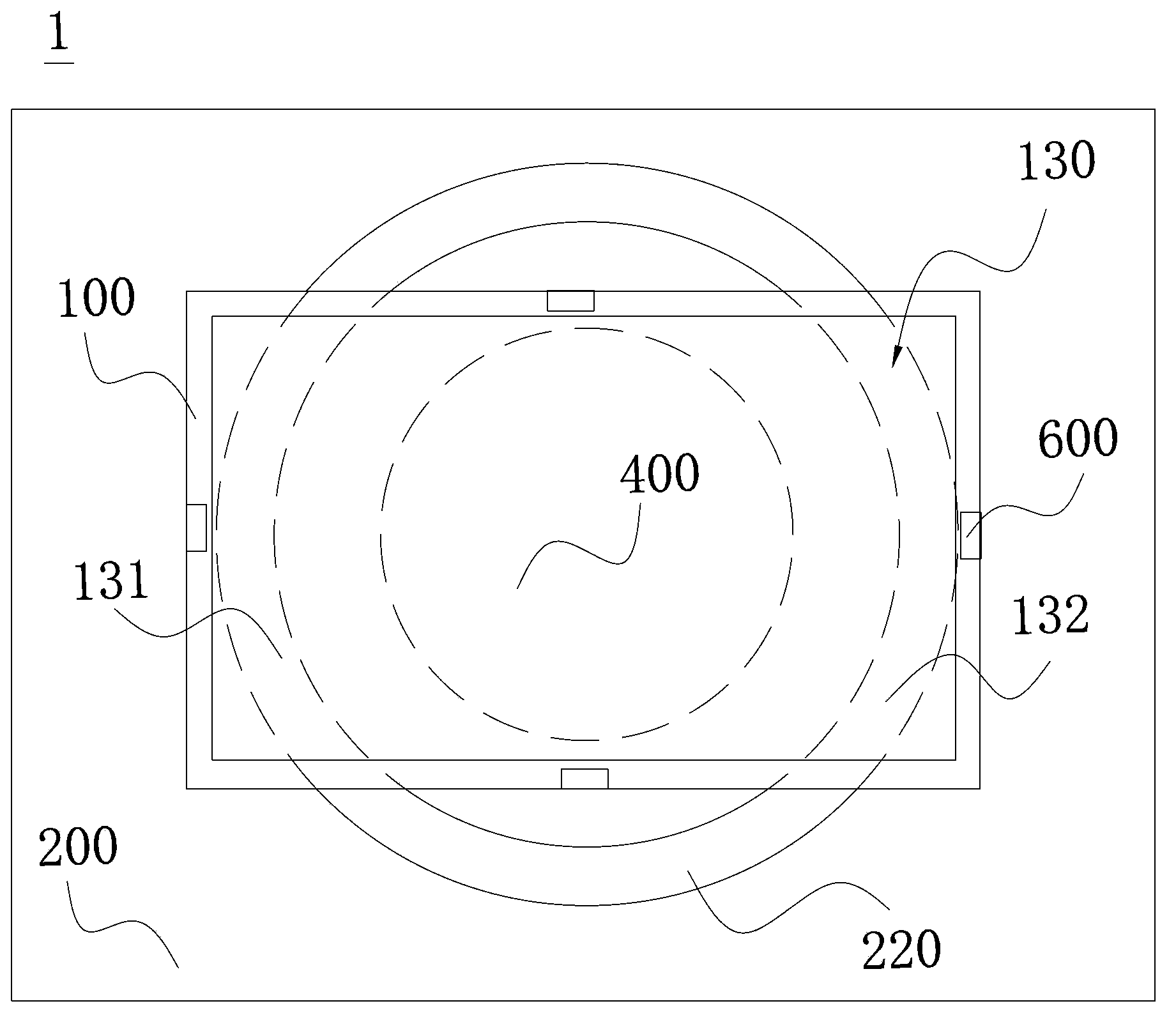

[0030] Please refer to Figure 2A , 2B , are schematic top and side views of the carrier device in the first state, respectively, in an embodiment of the present invention. The carrying device 1 of the present invention is mainly used for carrying the substrate 300, and the substrate can be a liquid crystal display panel or a touch panel, but not limited thereto, and it can also be other boards to be tested. Wherein, the carrying device 1 includes a stage 100 , a base 200 , a driving part 400 , at least one set of electromagnet modules 500 and at least one sensing module 600 . Wherein, in this embodiment, the carrying device 1 has a set of electromagnet modules 500 and four sensing modules 600 as an example for illustration. The stage 100 is arranged on the base 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com