socket electrical connection structure

A technology of electrical connection and socket, applied in the direction of contact parts, etc., can solve the problem of not being able to have convenient connection at the same time, and achieve the effects of convenient production, good versatility and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

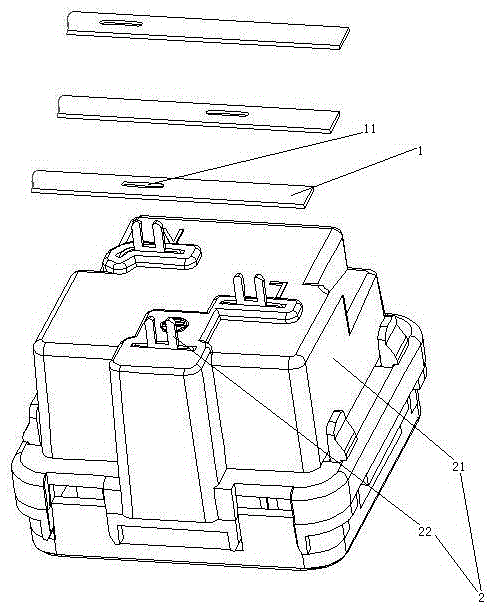

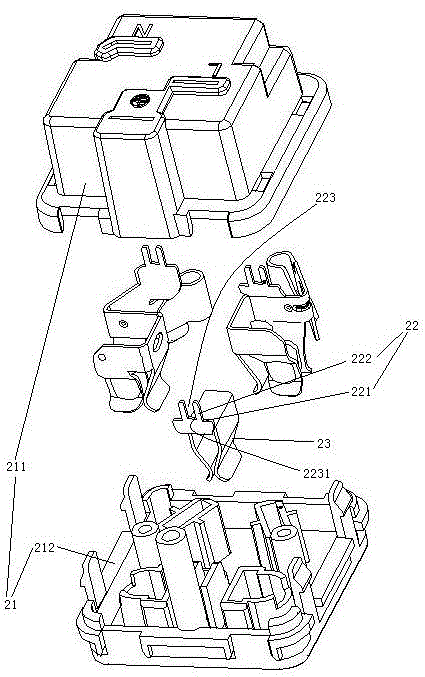

[0026] Embodiment one, see figure 1 , a socket electrical connection structure, comprising a conductive strip 1 and a socket module 2 . The socket module 2 includes an insulating shell 21 and a connector 22 passing through the shell. There are three connectors 22. The three connectors 22 are L-pole connectors, N-pole connectors and E-pole connectors respectively (some two-pole socket modules are not provided with E-pole connectors).

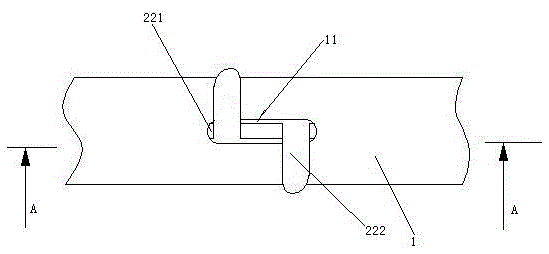

[0027] The conductive strip 1 is a flat structure. The width direction of the conductive strip 1 is parallel to the plane where the bottom surface of the casing 21 is located. The conductive strip 1 is a copper strip. There are three conductive strips 1. The three conductive strips 1 are L pole conductive strips, N pole conductive strips and E pole conductive strips respectively. The conductive strip 1 is provided with a connecting through hole 11 . The connection via hole 11 penetrates the conductive strip 1 along the thickness direction ...

Embodiment 2

[0034] Embodiment two, see Figure 5 , the difference from the first embodiment is that a solder joint 4 is provided between the connecting head 22 and the connecting through hole 11 . The solder joint 4 connects the connection head 22 and the busbar 1 together. The solder joint 4 is located between the two pins 222 .

Embodiment 3

[0035] Embodiment three, see Figure 6 , the difference from Embodiment 1 is that the two prongs 22 are bent in the same direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com