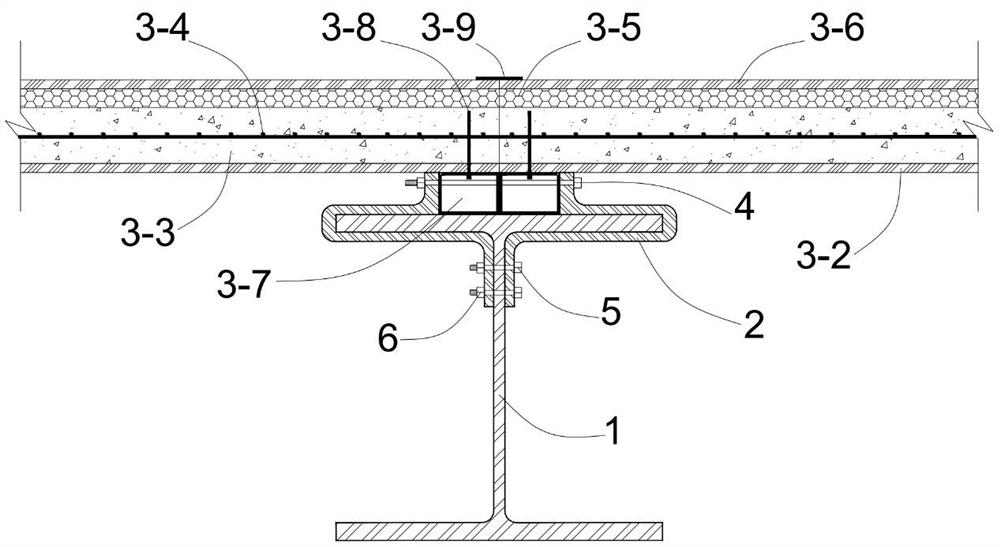

Connecting structure of steel frame light roof panel and H-shaped steel beam

A technology for connecting structures and roof panels, applied in the direction of floors, building components, building structures, etc., can solve the problems of complex stress on roof panels and steel beams, weakening the strength of drilled sections, and failure of roof panel welding, so as to adapt to the main structure. Deformation, saving installation time, simple effect of on-site assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

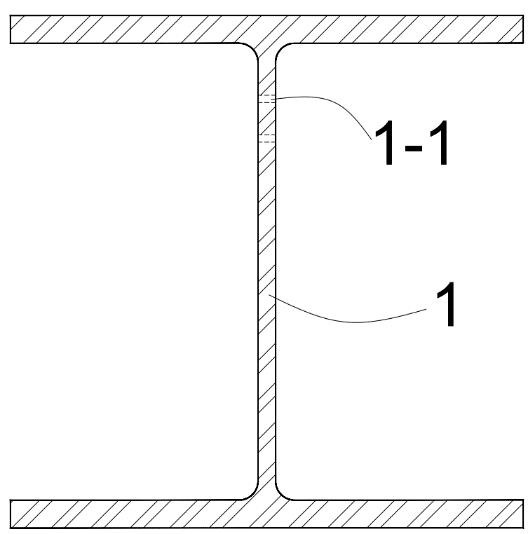

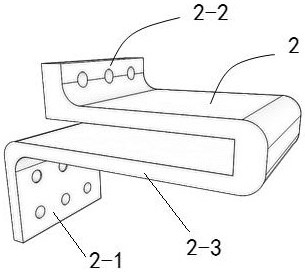

[0051] A connection structure between a steel frame lightweight roof panel and an H-shaped steel beam, including an H-shaped steel beam 1, a connector 2, and a steel frame lightweight roof panel 3, the connector 2 includes a first connecting section 2-1, a second The second connecting section 2-2, the third connecting section 2-3, the first connecting section 2-1, the second connecting section 2-2, and the third connecting section 2-3 enclose a half wing with the H-shaped steel beam 1 The outer edge matches the structure, the first connecting section 2-1 is set vertically upwards, and the two connecting pieces 2 are arranged on both sides of the top flange of the H-shaped steel beam 1, and the first connecting section 2 of the two connecting pieces 2 Two hollow square steel frames 3-7 are arranged between -1 and the two hollow square steel frames 3-7 occupy the area between the two first connecting sections 2-1. The two first connecting sections 2-1 and the hollow square steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com