Electronic component installation device and electronic component installation method

An electronic component installation, electronic component technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of no setting, complex structure, inability to properly cut off the empty supply belt with curling, and achieve the effect of eliminating blocking or winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

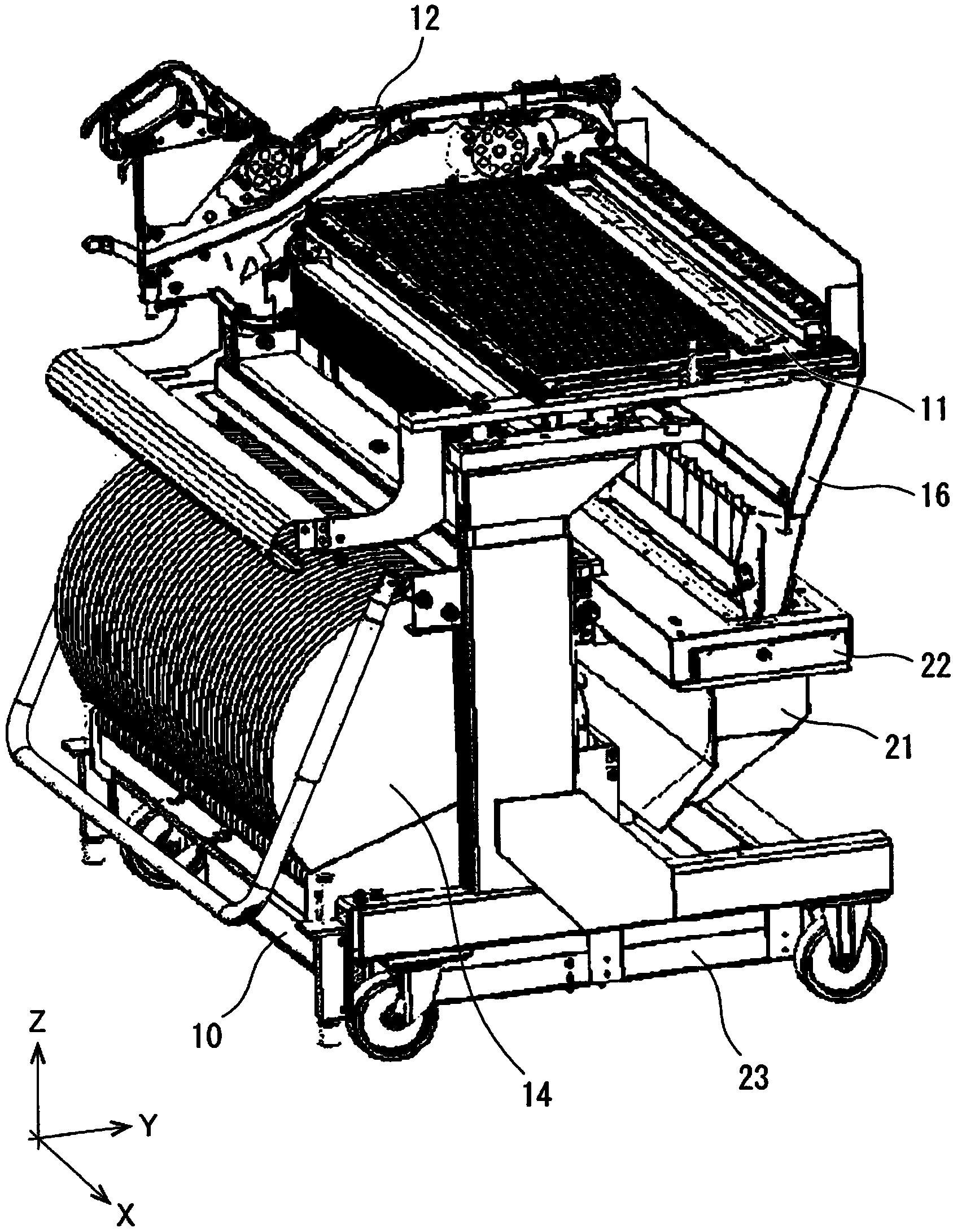

[0030] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a perspective view of the collective exchange stand showing a state mounted on the electronic component mounting device of the present embodiment, omitting a part of the main body of the mounting device.

[0031] The mass exchange stand 10 can be mounted to a predetermined position of the apparatus main body by moving forward in the horizontal direction, and can be removed by moving backward in the horizontal direction. A plurality of tape feeders 12 (in the figure 1 only one is shown).

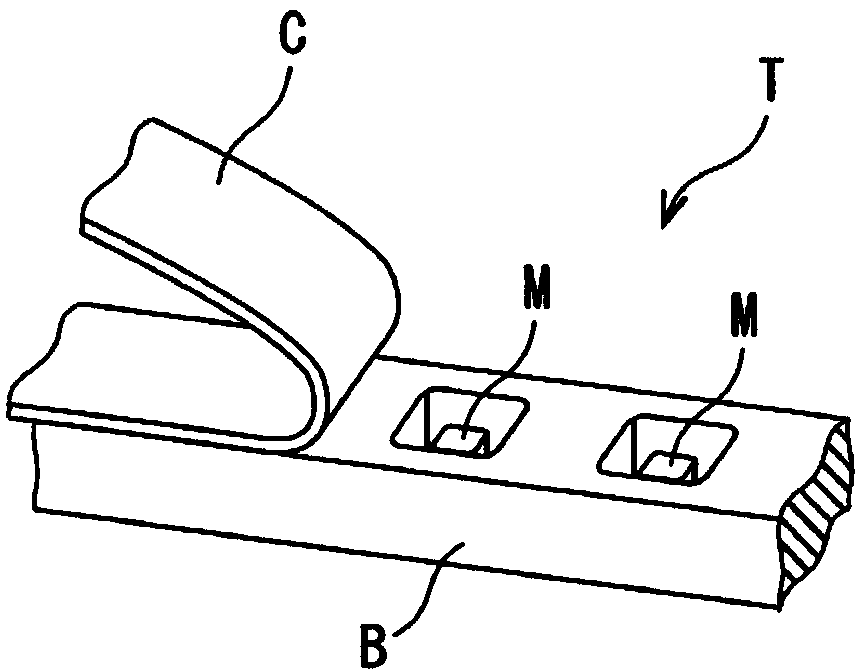

[0032] The tape feeder 12 feeds the carrier tape wound on the lower reel 14 in the downstream direction. like figure 2 As shown, the carrier tape T is composed of a strip-shaped base tape B and an outer cover tape C. A plurality of recesses are provided on the base tape B at intervals, and electronic components M are housed in the respective recesses. In addition, a cover tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com