Tomography-based calibration method of geometric position relationship of X-ray machine and detector

A calibration method and tomographic imaging technology, applied in the field of radiation imaging, can solve problems such as the influence of reconstructed image quality, the inability to accurately know the relative positional relationship between the detector and the X-ray machine, and the inability to obtain reconstructed images, etc., to improve image quality, remove blur effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below according to the drawings in the description and in combination with specific embodiments. For ease of understanding, the specification first describes the X-ray tomography system.

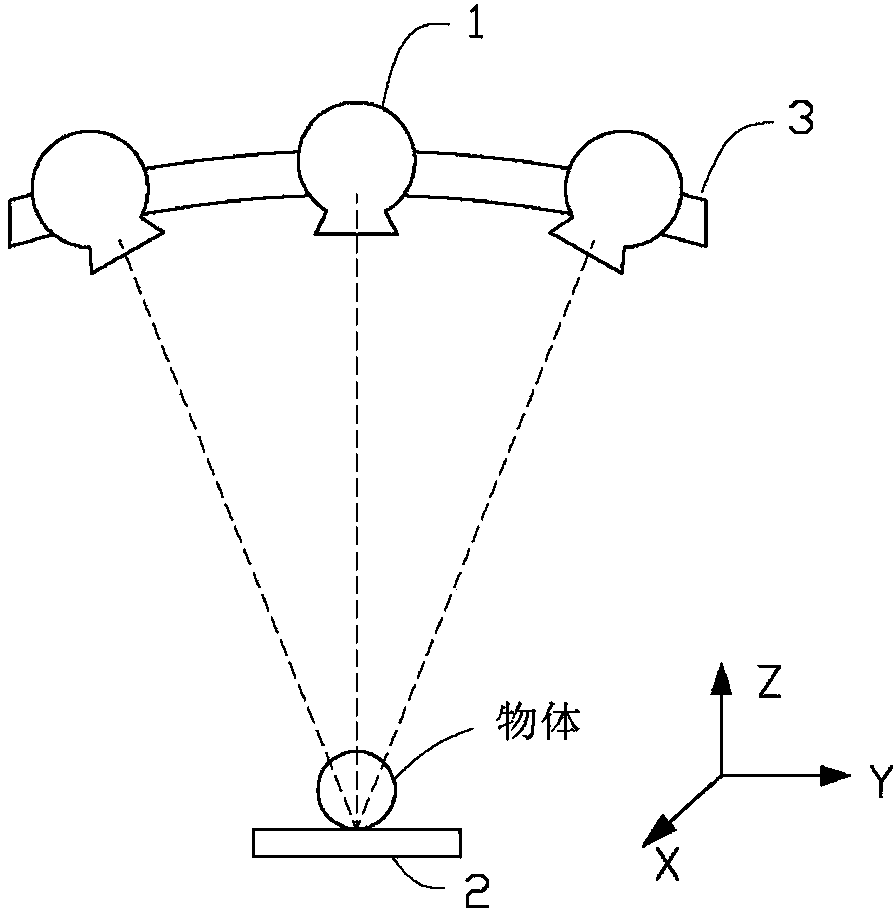

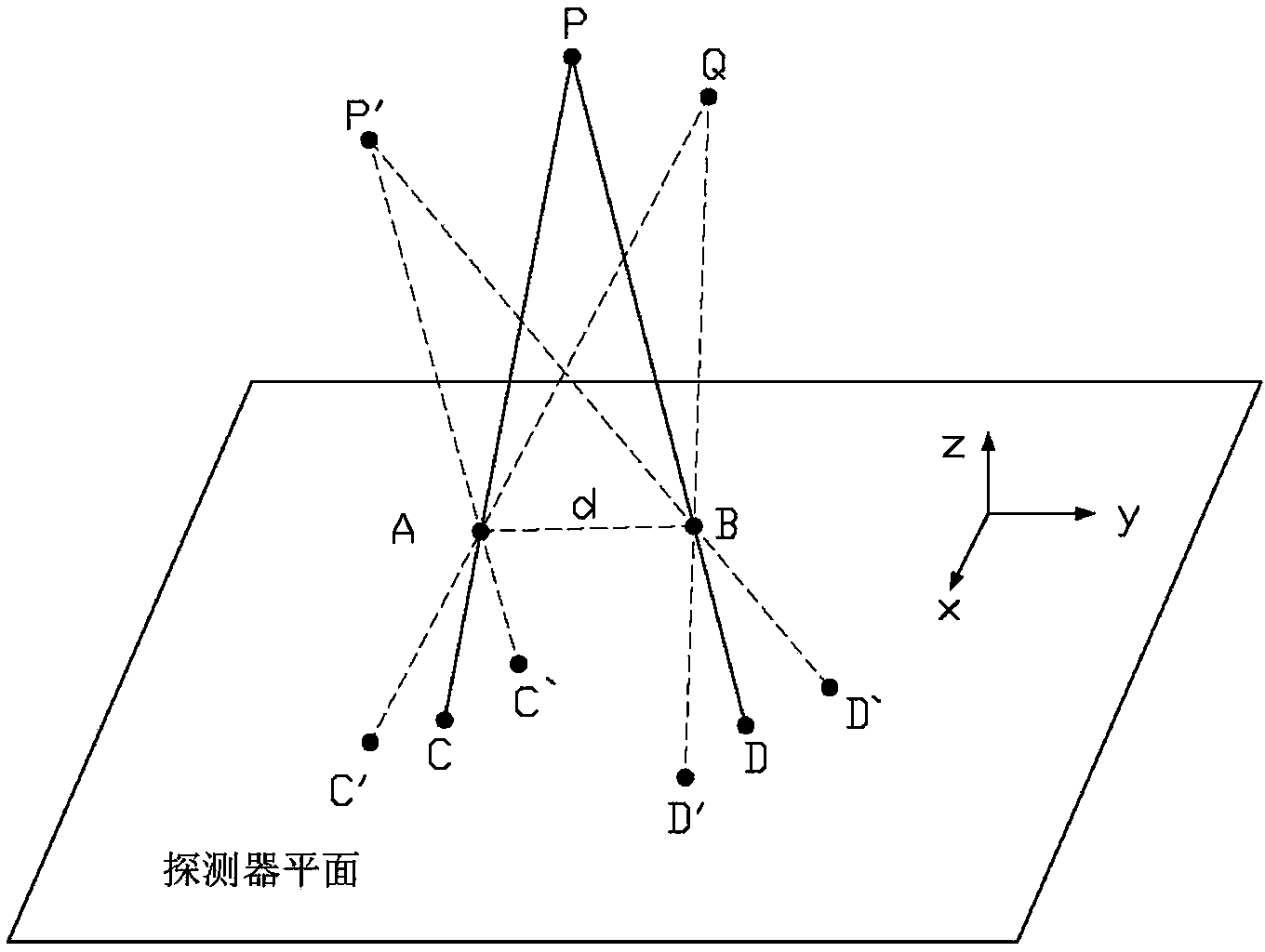

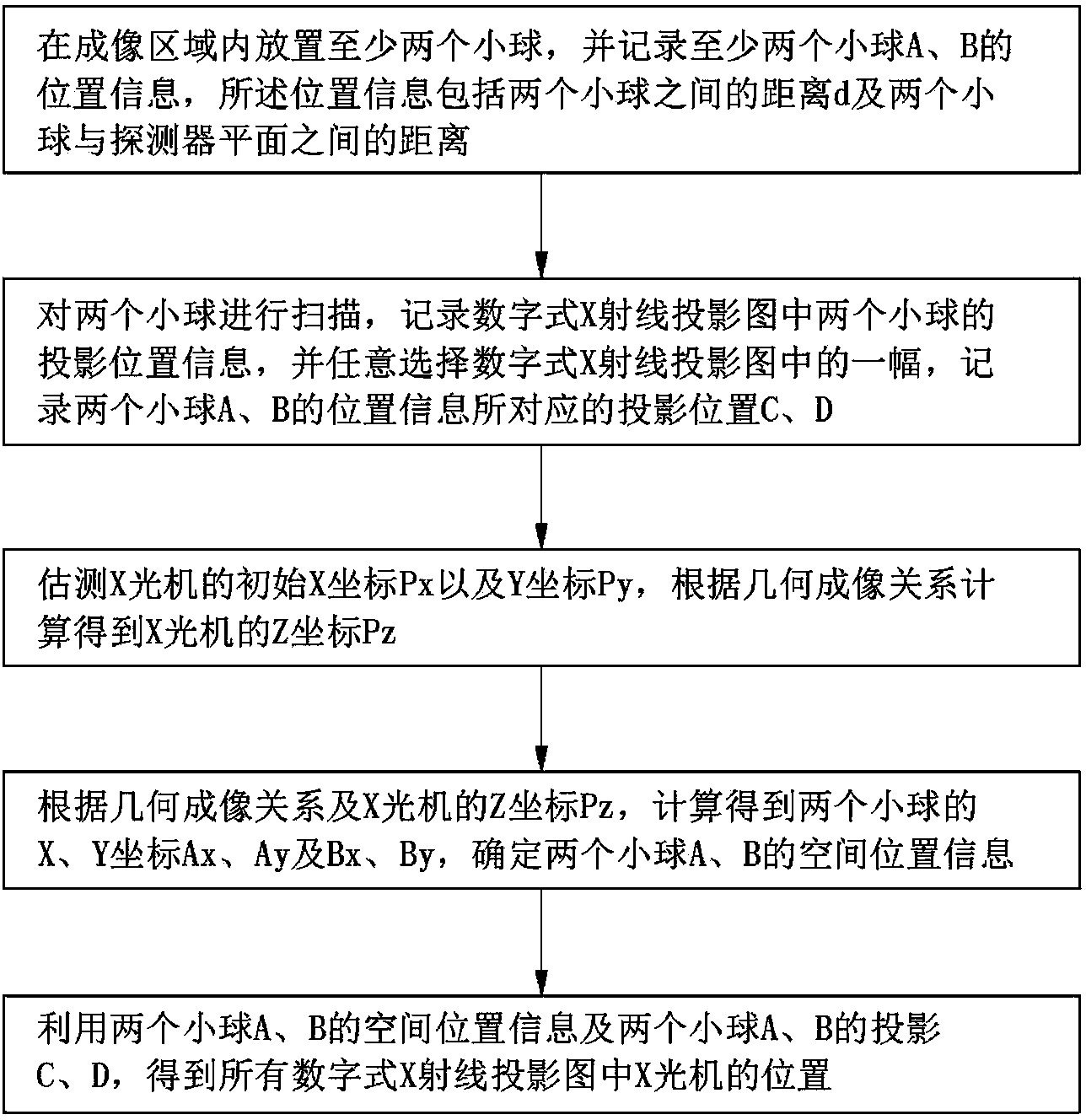

[0020] Please also refer to figure 1 , an embodiment of the present invention provides an X-ray tomography system, which mainly includes an X-ray machine 1 , an X-ray detector 2 and a track 3 . The X-ray machine 1 can move on the track 3, the X-ray detector 2 has a detector plane, the light emitted by the X-ray machine 1 is received by the X-ray detector 2, the X-ray machine 1 and the An imaging region is formed between the detector planes. When imaging, the object to be imaged is set on the detector plane. A coordinate system is established with the position of the X-ray detector 2 as the coordinate origin o, the plane where the detection plane is located as the x-y plane, and the z-axis perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com