Small-batch automatic oil injecting process

A small-batch, automatic technology, applied in spraying devices, coatings, devices for coating liquid on surfaces, etc., can solve problems such as poor fuel injection quality, slow fuel injection speed, and manual fuel injection technology that is not suitable for small batch production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

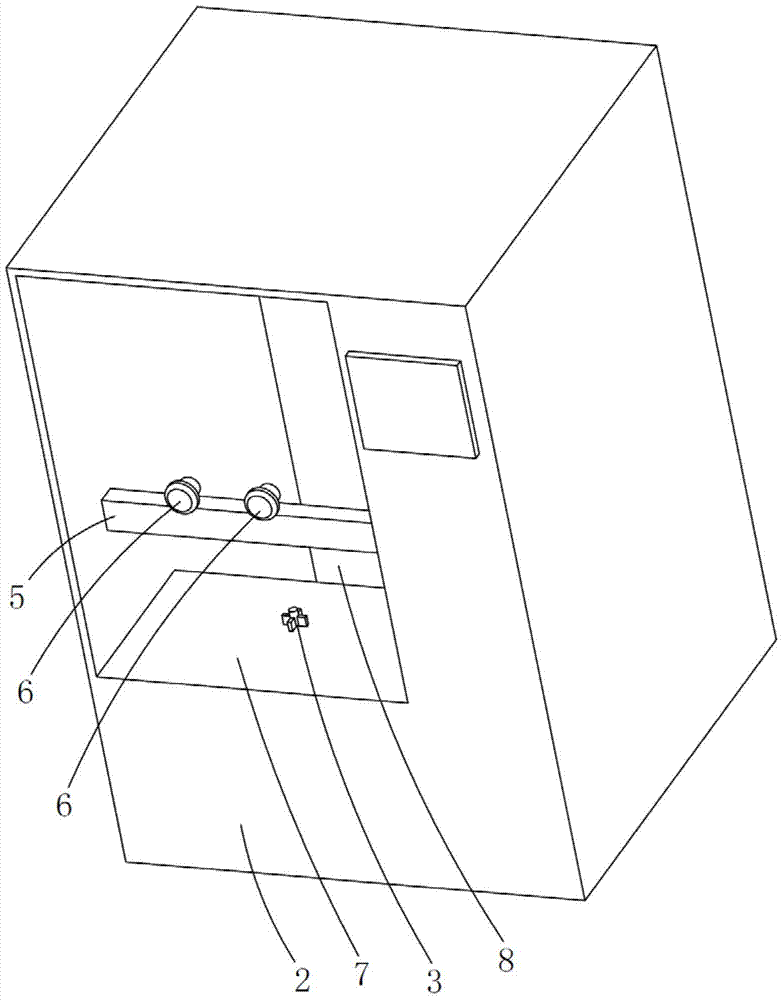

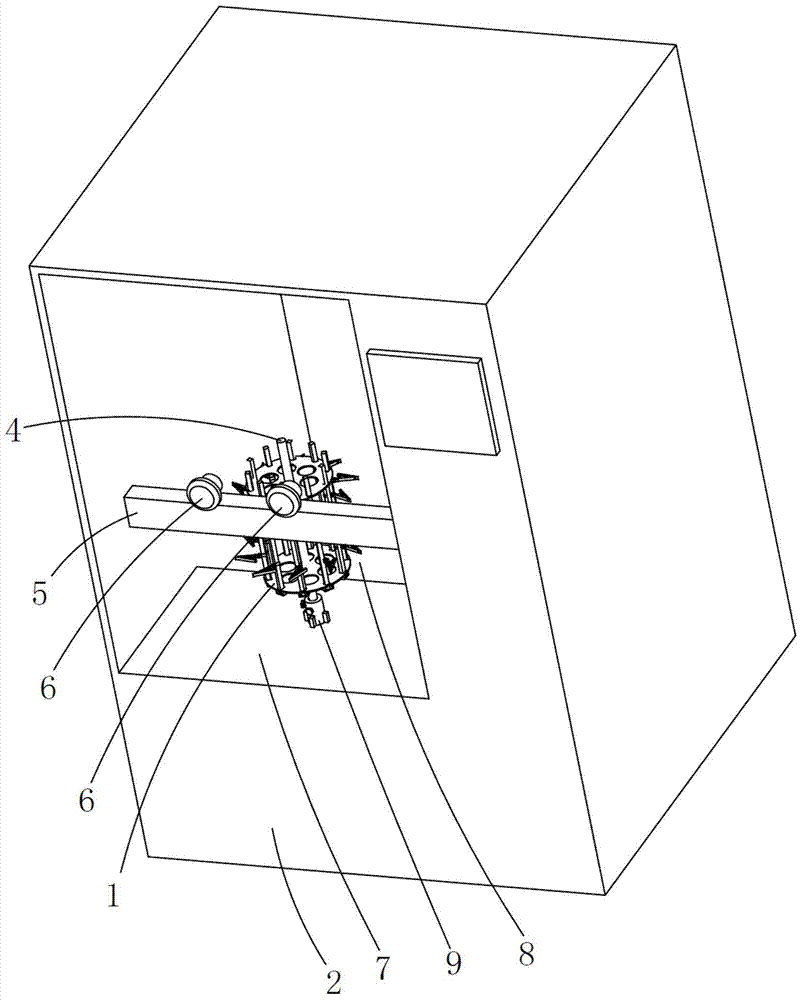

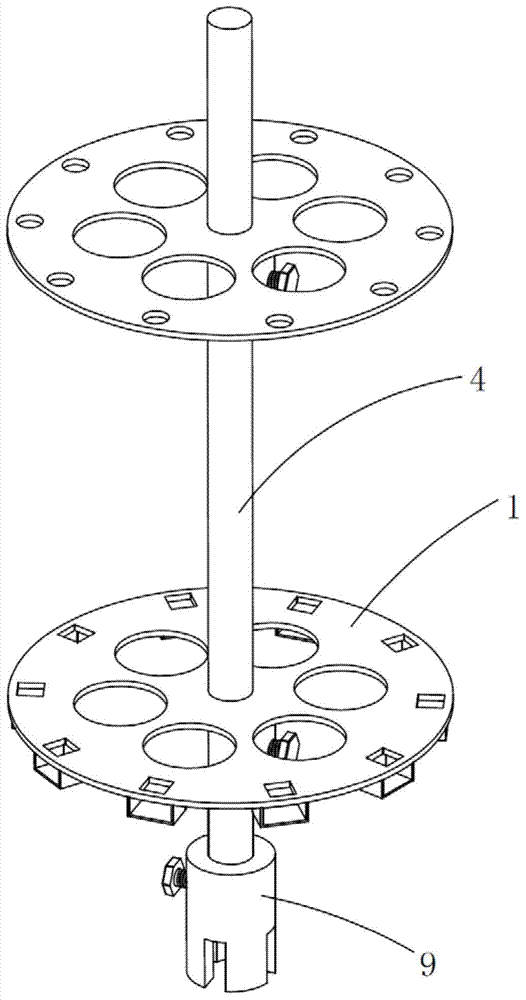

[0031] example, see Figure 1 to Figure 4 shown,

[0032] A small batch automatic fuel injection process, comprising the following steps,

[0033] In the clamping step, several products are respectively clamped in a rotary fixture 1 with a rotating shaft 4 in the middle, and the products are clamped in the annular area of the outer edge of the rotary fixture 1, and arranged along the height direction of the rotary fixture 1. Products with multiple layers; the rotary clamp 1 can be equipped with auxiliary positioning mechanisms or clamps to improve the convenience of clamping and positioning products;

[0034] Use fuel injector 2 for fuel injection;

[0035] The rotating shaft 3 provided on the automatic fuel injection table 7 of the fuel injector 2 provides a rotary motion for the rotary clamp 1, the rotatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap