L-shaped non-trace bending die

A technology of bending dies and shaped parts, which is applied in the field of L-shaped parts without trace bending dies, can solve the problems of scratches and other problems of formed parts, and achieve the effect of stable function and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

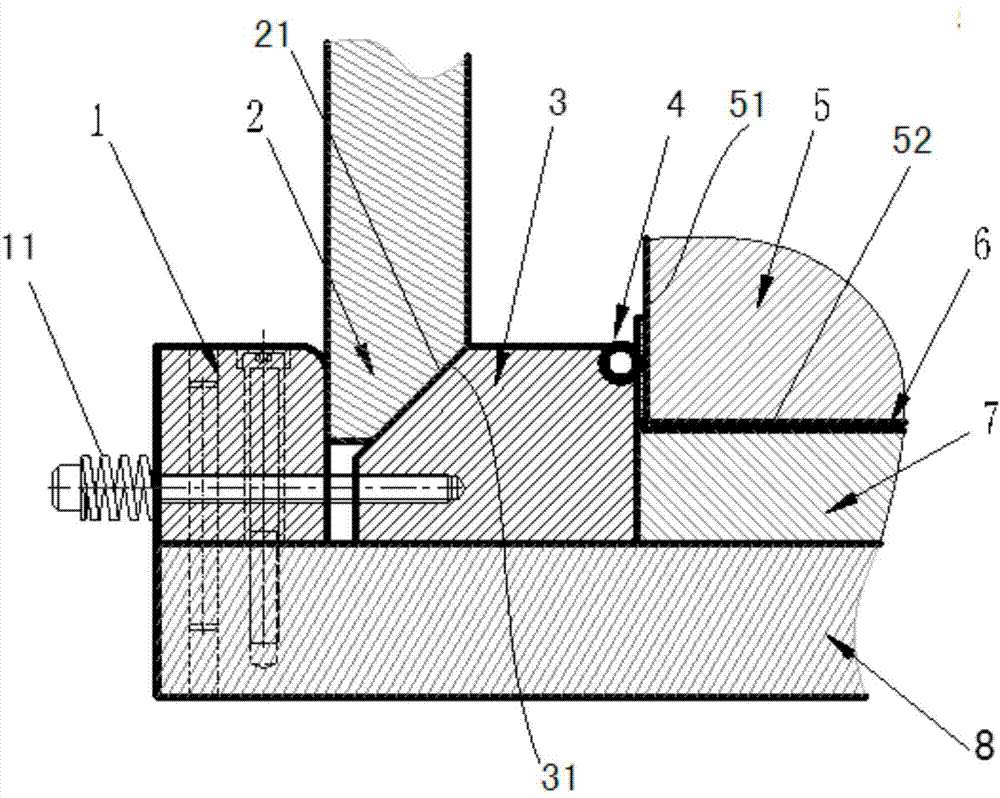

[0020] The no-mark bending mold for L-shaped parts includes an upper template and a lower template 8, and the upper and lower templates are arranged oppositely, and the upper template can move in the up and down direction, and the upper punch 5 is arranged on the upper template, and the upper punch 5 has a second A bending surface 51 and a second bending surface 52, the lower push die 3 is slidably arranged on the lower template 8 in the direction close to the upper punch 5 and away from the upper punch 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com