Lower knife shaft locking device of aluminum strip splitting machine

A slitting machine and shaft locking technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve problems such as radial runout and affecting the accuracy of slitting aluminum strips, and achieve the elimination of radial runout , simple structure, and the effect of improving the quality of slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

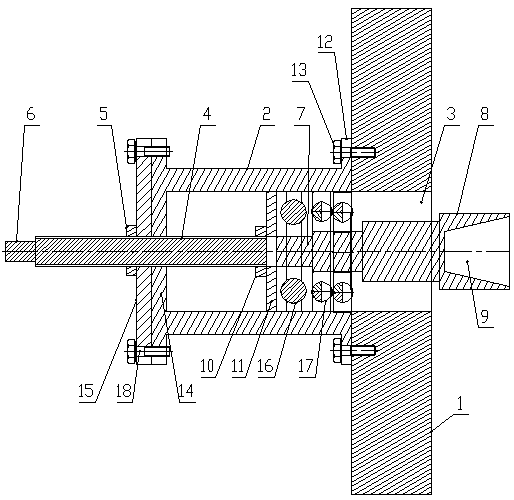

[0011] Such as figure 1 As shown, the lower cutter shaft locking device of the aluminum strip slitting machine of the present invention includes a vertical plate 1, the outer side of the vertical plate 1 is provided with a cylinder 2 arranged horizontally, and the vertical plate 1 is provided with a cylinder connected to the inner end of the cylinder 2. Through hole 3, the inner diameter of the through hole 3 is equal to the inner diameter of the cylinder body 2, the outer end of the cylinder body 2 is provided with a blocking plate, the center of the blocking plate is provided with a threaded hole, the threaded hole is horizontally threaded with a screw 4, and the screw 4 is threaded There is a fixed nut 5 that presses against the outer surface of the blocking plate, an operating head 6 is provided at the outer end of the screw rod 4, a bearing is provided inside the cylinder body 2, and the inner ring of the bearing is connected with a stepped shaft 7 that is small on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com