Track locomotive braking clamp unit brake block gap adjuster

A technology of vehicle brake caliper and gap adjuster, which is applied in the direction of brake wear compensation mechanism, railway braking system, railway car body parts, etc. problems, to achieve the effect of simple structure, small footprint, and high modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

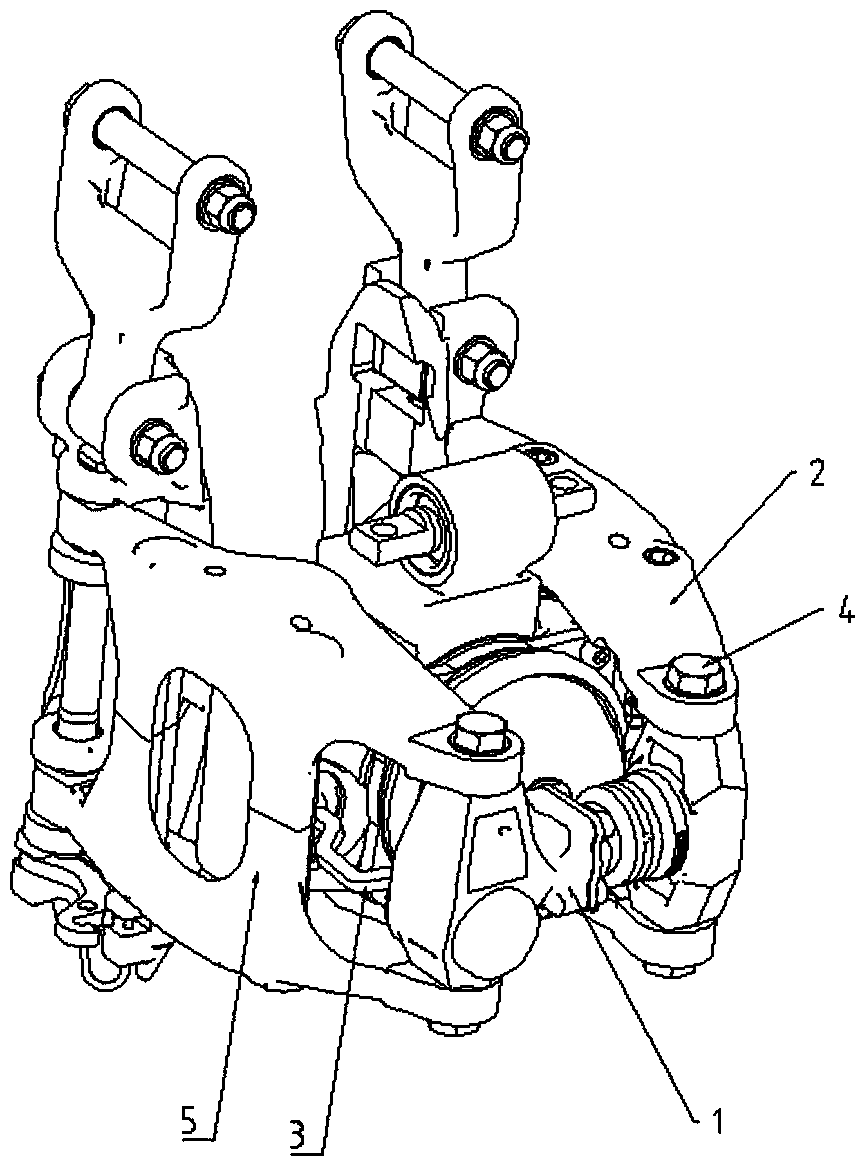

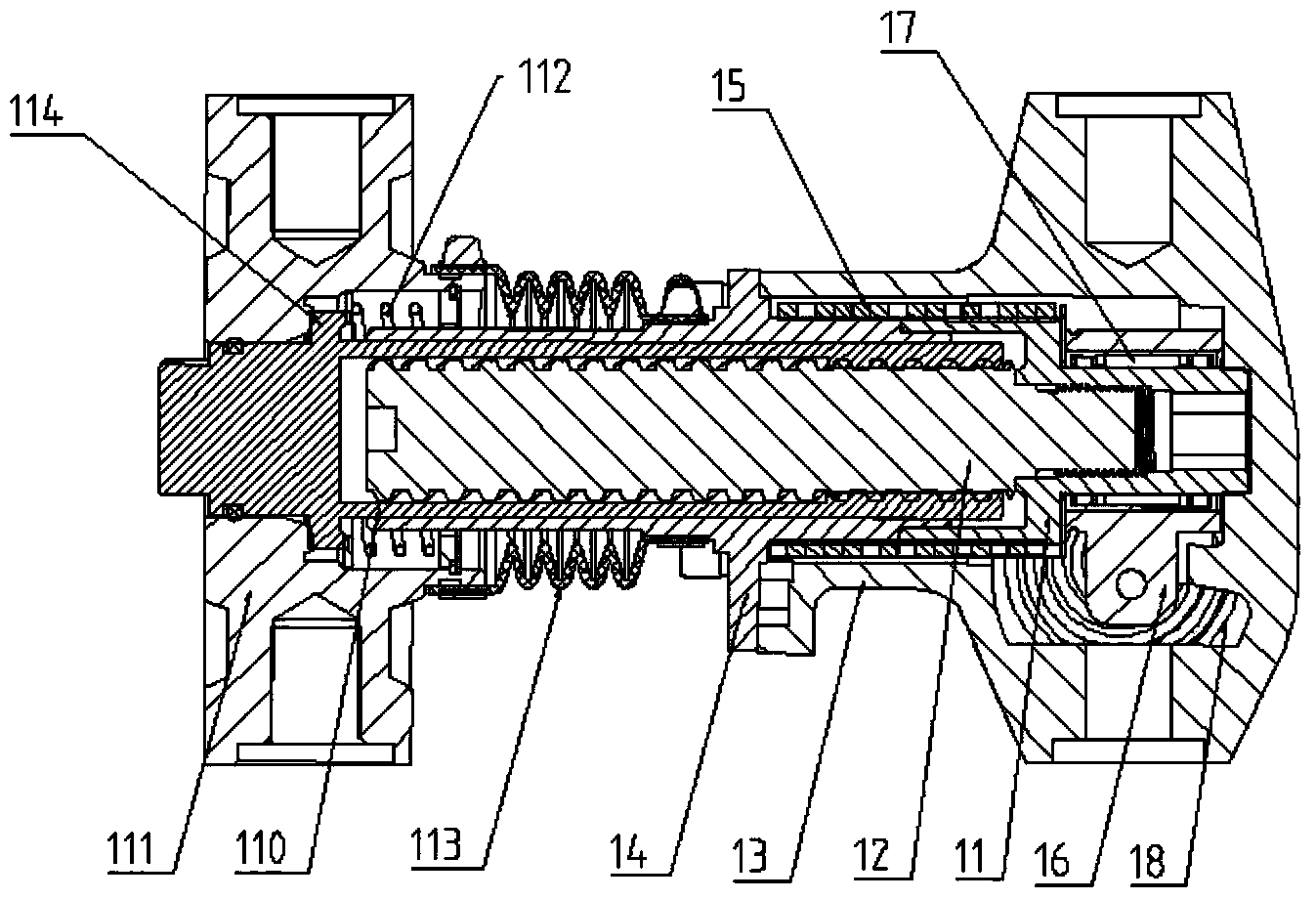

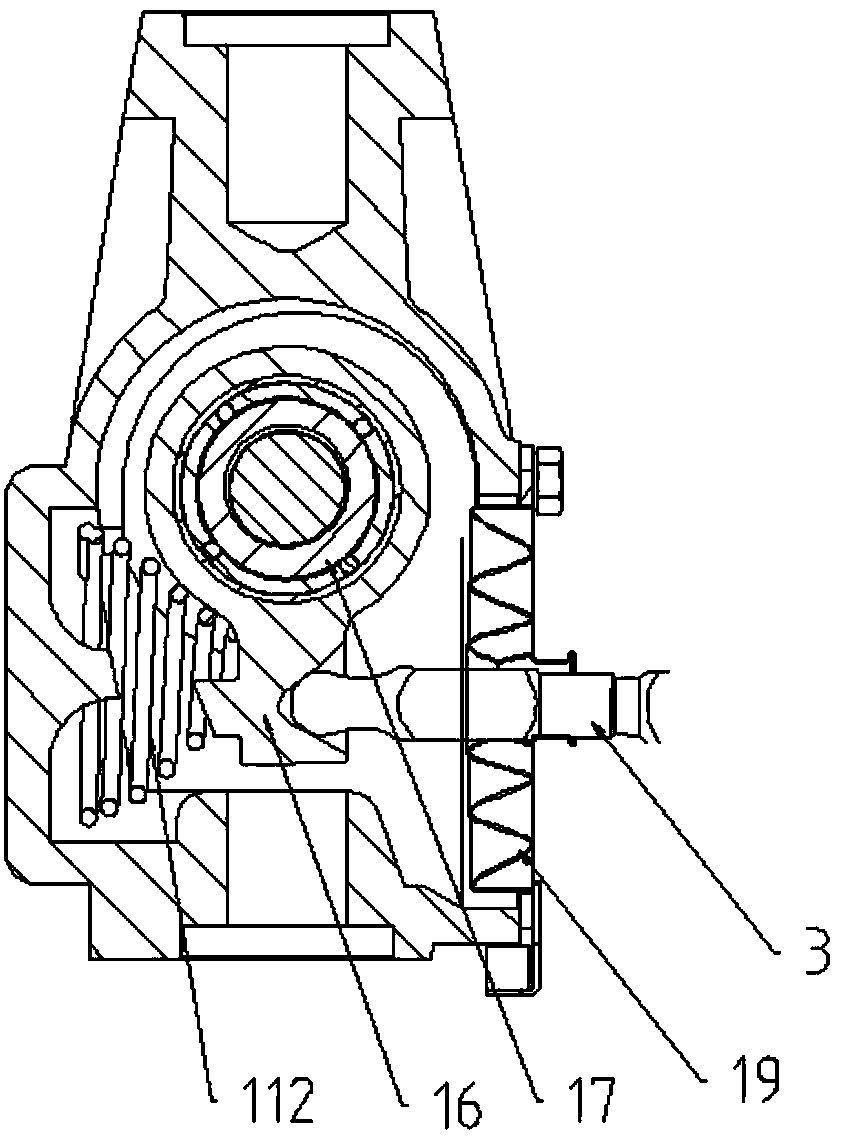

[0018] The rail locomotive vehicle brake caliper unit brake pad gap adjuster 1 of the present embodiment comprises a left box body 13 and a right box body 111, and the upper and lower ends of the left box body 13 and the right box body 111 are respectively provided with connecting ends, and the left box body 13 and the right box body 111 are respectively provided with connecting ends. The box 13 and the right box 111 are respectively hinged with the left brake caliper arm 5 and the right brake caliper arm 2 of the brake caliper unit through the pin 4, and the left box 13 is provided with a one-way torsion spring friction Clutch, friction shaft 11 and lead screw 12 are fixedly connected by left-handed thread to form a driving shaft; connecting pipe 14 is fastened on the left box body 13, and friction torsion spring 15 is set to hold the connecting pipe 14 and friction shaft 11 tightly; connecting pipe 14 and The outer diameter of the part where the friction shaft 11 is held tigh...

Embodiment 2

[0020] The rail locomotive vehicle brake caliper unit brake pad gap adjuster of this embodiment is the same as Embodiment 1 except for the following differences:

[0021] A corrugated disk-type rubber dustproof cover 19 is provided at the contact opening of the left box body 13 and the push rod 3 . A flexible bellows-type rubber dustproof cover 113 is provided on the outside of the joint between the left box body 13 and the right box body 111, and has a breathing hole.

[0022] During use, the connecting ends of the left box body 13 and the right box body 111 of the rail vehicle brake caliper unit brake pad clearance adjuster 1 are respectively connected with the left brake caliper arm 5 and the right brake caliper of the brake caliper unit. The pliers arm 2 is hinged through the pin shaft 4, and the rotating arm sleeve 16 and the push rod 3 are hinged through a spherical pair.

[0023] When there is a situation or trend that the gap between the brake pads is too large due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com