Bean vermicelli winding and binding mechanism and processing method thereof

A technology of binding mechanism and vermicelli, applied in the direction of binding materials, paper/cardboard containers, containers, etc., can solve the problems of low work efficiency, affecting product production efficiency, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

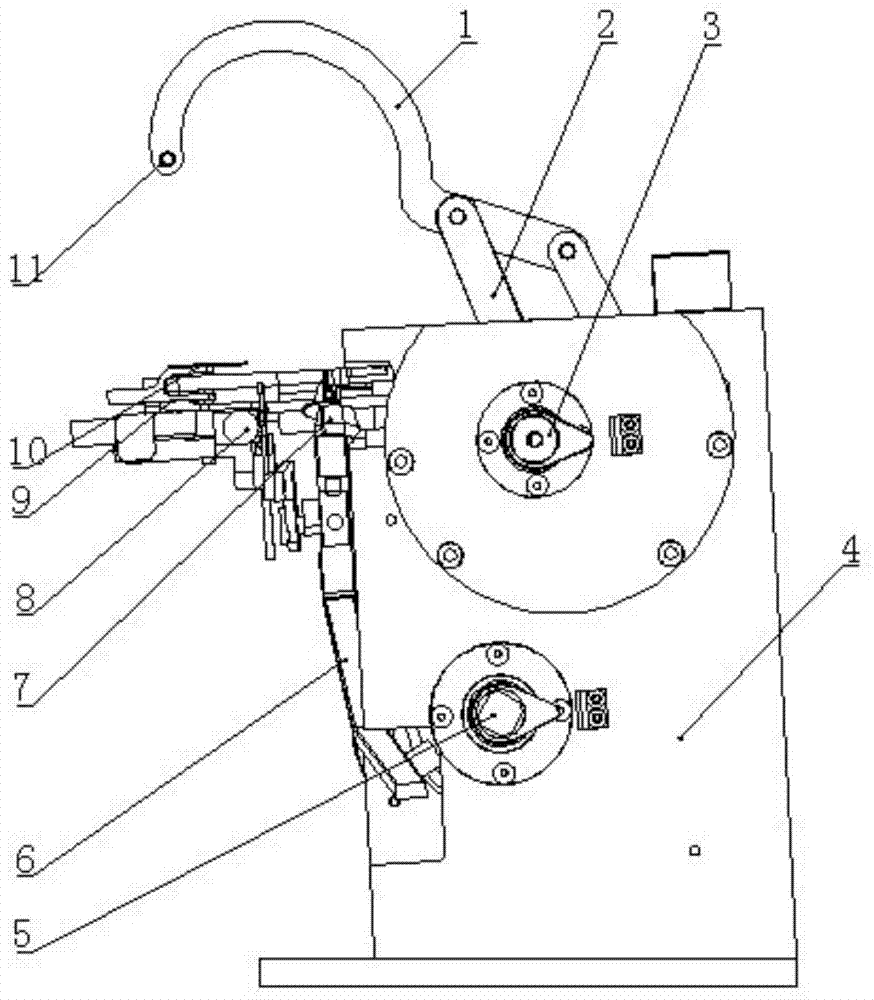

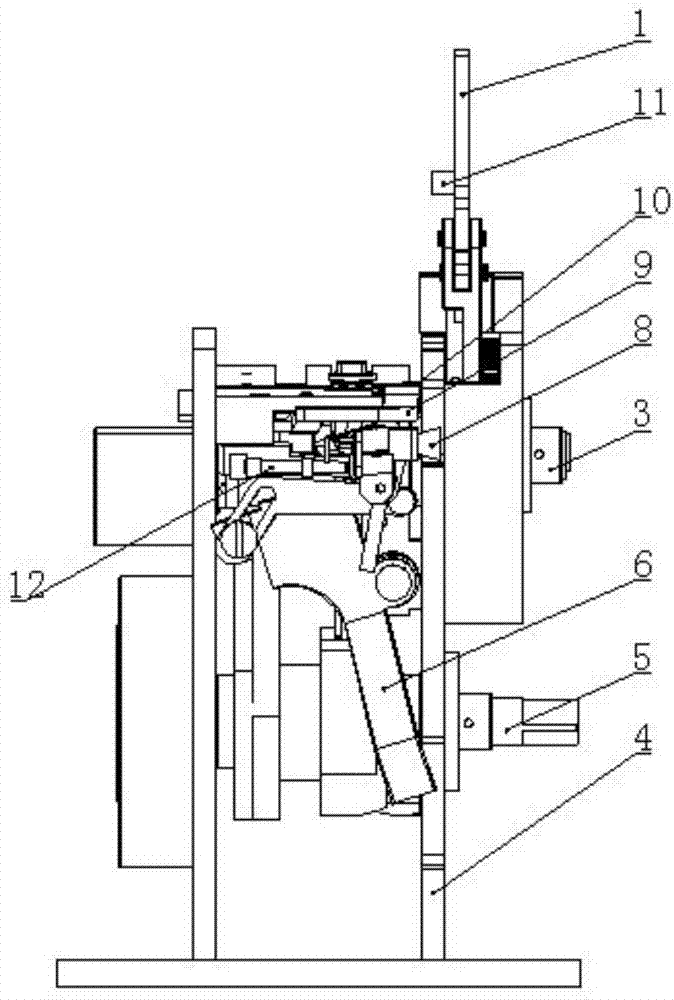

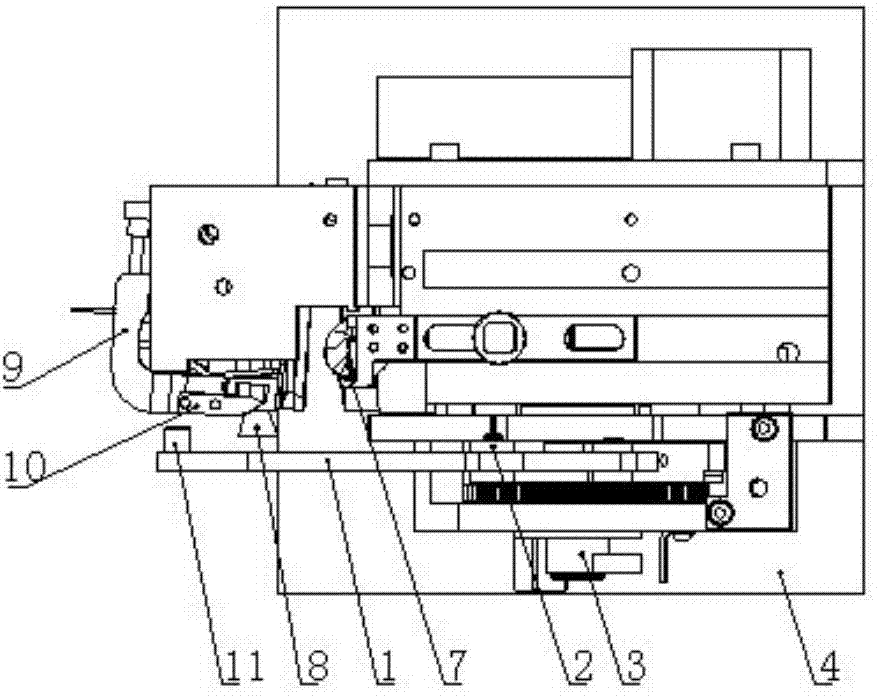

[0021] A vermicelli winding and binding mechanism, comprising a fixed frame 4, a driving shaft 3, a swing lever 1, a hinge four-bar mechanism 2, a wire feeding sleeve 11, a fixed wire clip 8, a twisting and binding device 7, a swing arm 6, and a swing arm drive shaft 5. The driving device 12, the wire-pushing bent plate 9 and the blade 10, the fixed frame is a cubic box structure, the upper part of the fixed frame is horizontally installed with a driving shaft, and the driving shaft is driven and installed with a swing rod. The specific installation structure of this embodiment is Drive the hinge shaft on the driving shaft-a hinge four-bar mechanism arranged on a vertical plane. The upper movable rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com