A wind-coal blowing furnace and a wind-coal blowing furnace smelting method for tin concentrate

A technology of air-coal blowing furnace and smelting method, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of increasing energy, environment, site cost, etc., and achieve the effects of strong material adaptability, low material requirements and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

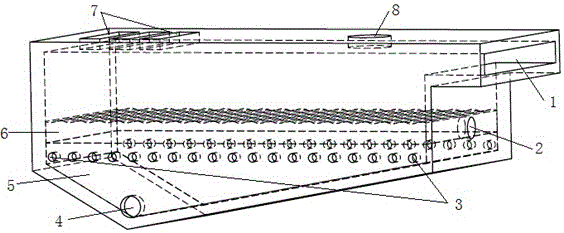

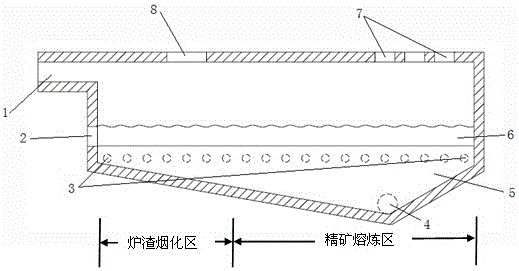

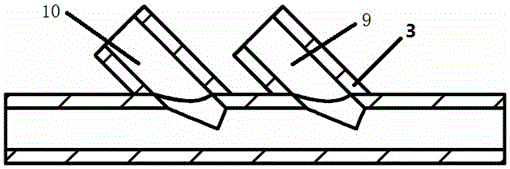

[0023] Such as Figures 1 to 3 As shown, the air-coal blowing furnace includes a furnace body, a flue 1, a slag outlet 2, a tin outlet 5 and a raw material inlet 7, and also includes an air-coal blowpipe 6 and a pyrite inlet 8, and the furnace body is in the form of a column body, the bottom of the furnace body is conical, and the furnace body is divided into a concentrate smelting area and a slag fuming area, and the top of the furnace body is provided with a raw material inlet 7 and a pyrite inlet 8 corresponding to the concentrate smelting area and the slag fuming area, respectively. There is a tin outlet 5 on one side of the cone, and the wind coal blowing pipe 6 is symmetrically located at the lower part of the front and rear sides of the furnace body. A flue 1 is provided on the upper side of the side of the furnace body, and a slag outlet is provided on the same side of the lower end of the flue 1. Mouth 2.

[0024] Among them, the wind coal blowpipe 6 is located betwe...

Embodiment 2

[0029] Such as Figures 1 to 3 As shown, the air-coal blowing furnace includes a furnace body, a flue 1, a slag outlet 2, a tin outlet 5 and a raw material inlet 7, and also includes an air-coal blowpipe 6 and a pyrite inlet 8, and the furnace body is in the form of a column body, the bottom of the furnace body is conical, and the furnace body is divided into a concentrate smelting area and a slag fuming area, and the top of the furnace body is provided with a raw material inlet 7 and a pyrite inlet 8 corresponding to the concentrate smelting area and the slag fuming area, respectively. There is a tin outlet 5 on one side of the cone, and the wind coal blowing pipe 6 is symmetrically located at the lower part of the front and rear sides of the furnace body. A flue 1 is provided on the upper side of the side of the furnace body, and a slag outlet is provided on the same side of the lower end of the flue 1. Mouth 2.

[0030]Among them, the wind coal blowpipe 6 is located betwee...

Embodiment 3

[0035] Such as Figures 1 to 3 As shown, the air-coal blowing furnace includes a furnace body, a flue 1, a slag outlet 2, a tin outlet 5 and a raw material inlet 7, and also includes an air-coal blowpipe 6 and a pyrite inlet 8, and the furnace body is in the form of a column body, the bottom of the furnace body is conical, and the furnace body is divided into a concentrate smelting area and a slag fuming area, and the top of the furnace body is provided with a raw material inlet 7 and a pyrite inlet 8 corresponding to the concentrate smelting area and the slag fuming area, respectively. There is a tin outlet 5 on one side of the cone, and the wind coal blowing pipe 6 is symmetrically located at the lower part of the front and rear sides of the furnace body. A flue 1 is provided on the upper side of the side of the furnace body, and a slag outlet is provided on the same side of the lower end of the flue 1. Mouth 2.

[0036] Among them, the wind coal blowpipe 6 is located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com